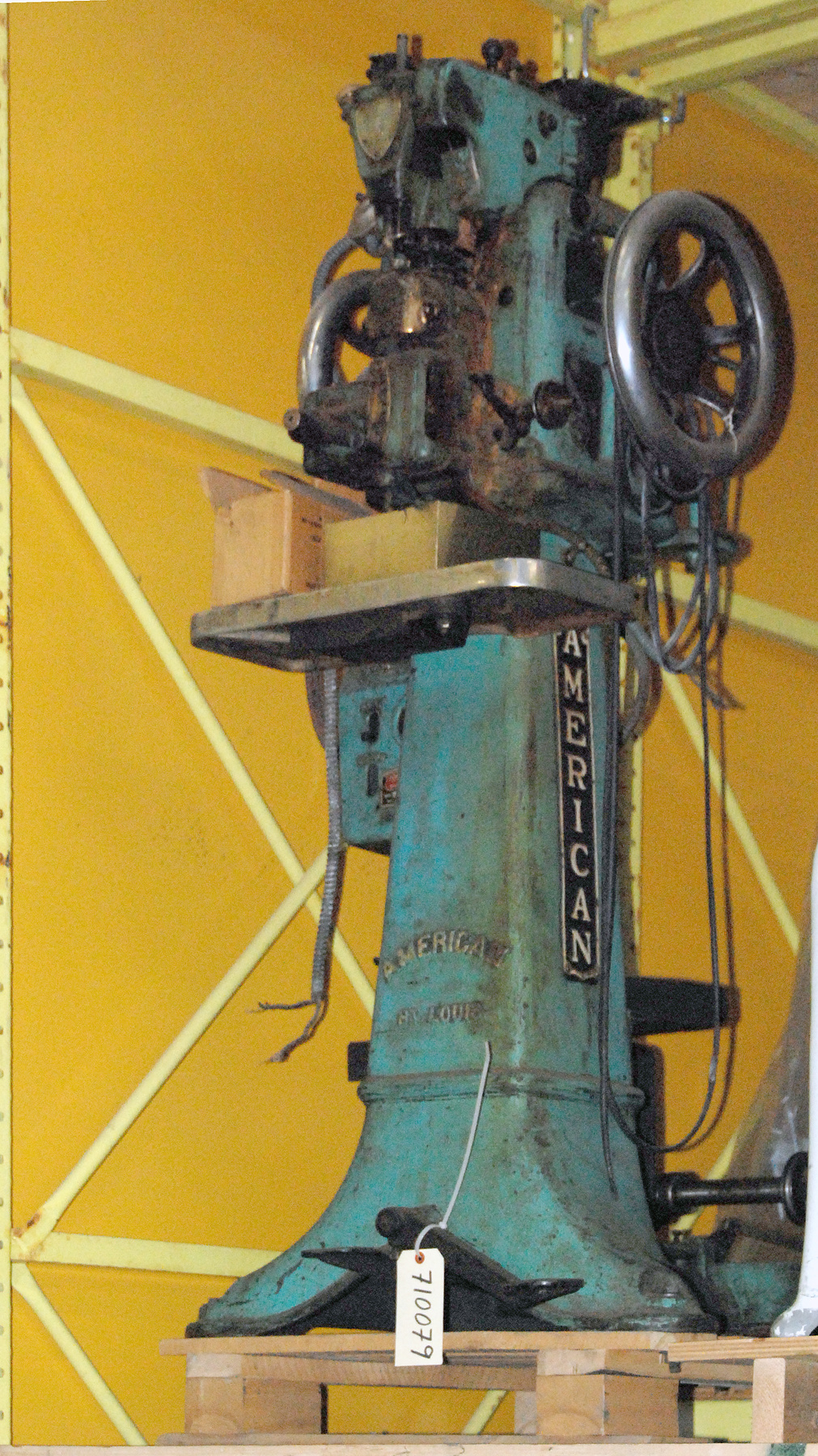

Stitcher

Use this image

Can I reuse this image without permission? Yes

Object images on the Ingenium Collection’s portal have the following Creative Commons license:

Copyright Ingenium / CC BY-NC-ND (Attribution-NonCommercial 4.0 International (CC BY-NC 4.0)

ATTRIBUTE THIS IMAGE

Ingenium,

2008.1637.001

Permalink:

Ingenium is releasing this image under the Creative Commons licensing framework, and encourages downloading and reuse for non-commercial purposes. Please acknowledge Ingenium and cite the artifact number.

DOWNLOAD IMAGEPURCHASE THIS IMAGE

This image is free for non-commercial use.

For commercial use, please consult our Reproduction Fees and contact us to purchase the image.

- OBJECT TYPE

- MOTORIZED

- DATE

- Unknown

- ARTIFACT NUMBER

- 2008.1637.001

- MANUFACTURER

- American Shoe Machinery & Tool Co.

- MODEL

- B

- LOCATION

- St. Louis, Missouri, United States of America

More Information

General Information

- Serial #

- N/A

- Part Number

- 1

- Total Parts

- 3

- AKA

- N/A

- Patents

- N/A

- General Description

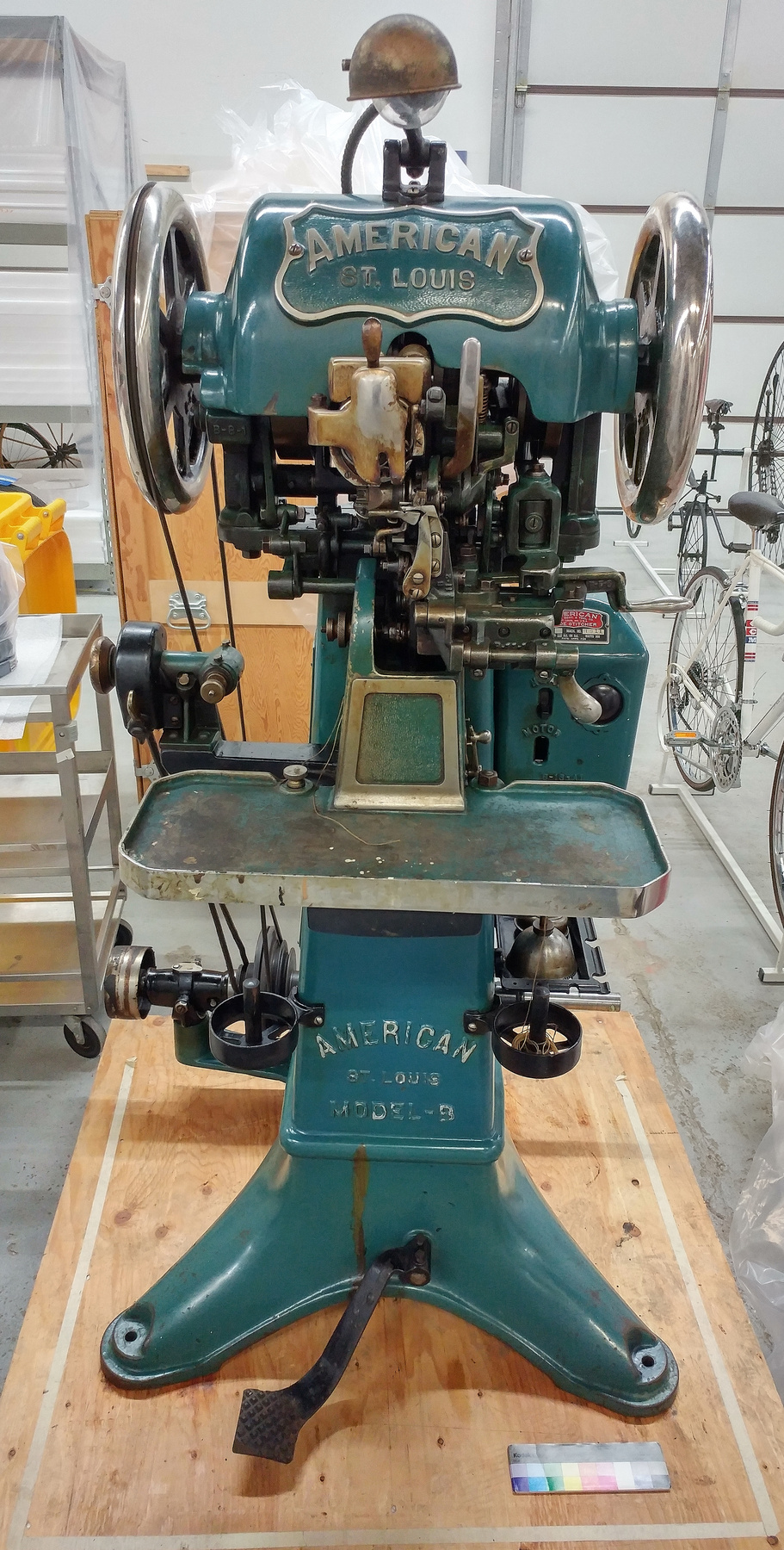

- Metal casing and parts with a glass light bulb and a synthetic cord cover

Dimensions

Note: These reflect the general size for storage and are not necessarily representative of the object's true dimensions.

- Length

- 89.5 cm

- Width

- 85.0 cm

- Height

- 157.0 cm

- Thickness

- N/A

- Weight

- N/A

- Diameter

- N/A

- Volume

- N/A

Lexicon

- Group

- Industrial Technology

- Category

- Tools & equipment-trades

- Sub-Category

- N/A

Manufacturer

- AKA

- American Shoe

- Country

- United States of America

- State/Province

- Missouri

- City

- St. Louis

Context

- Country

- Canada

- State/Province

- Ontario

- Period

- ca. 1932-1999

- Canada

-

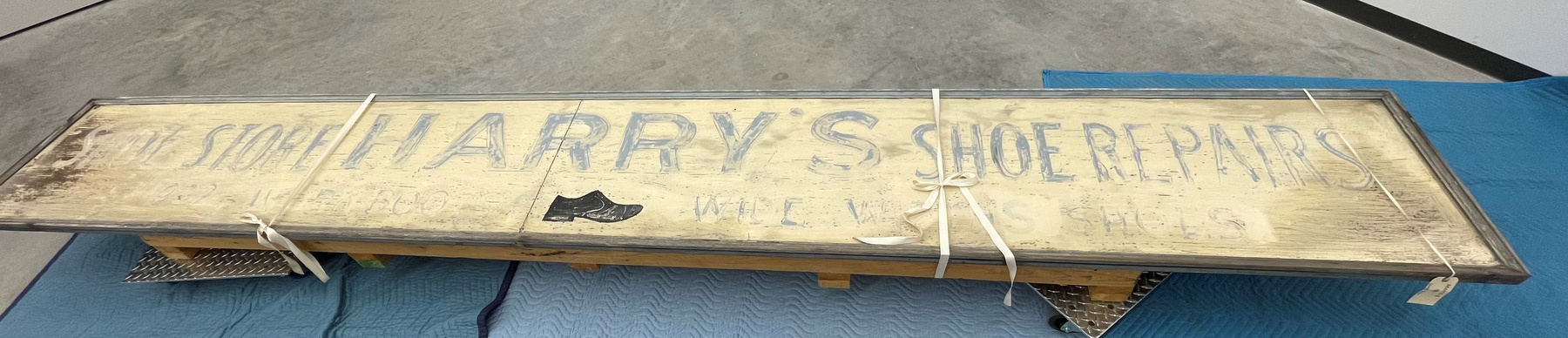

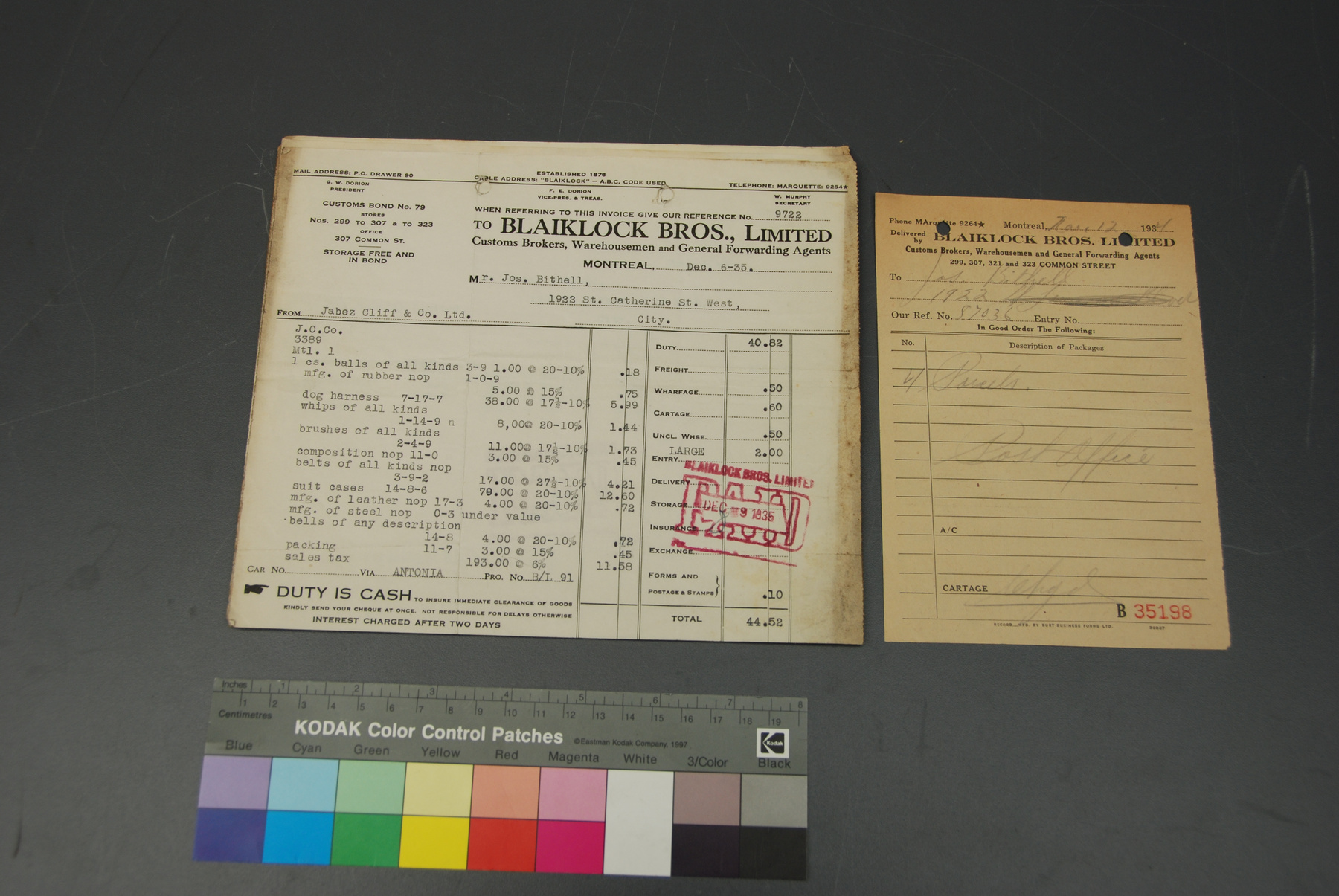

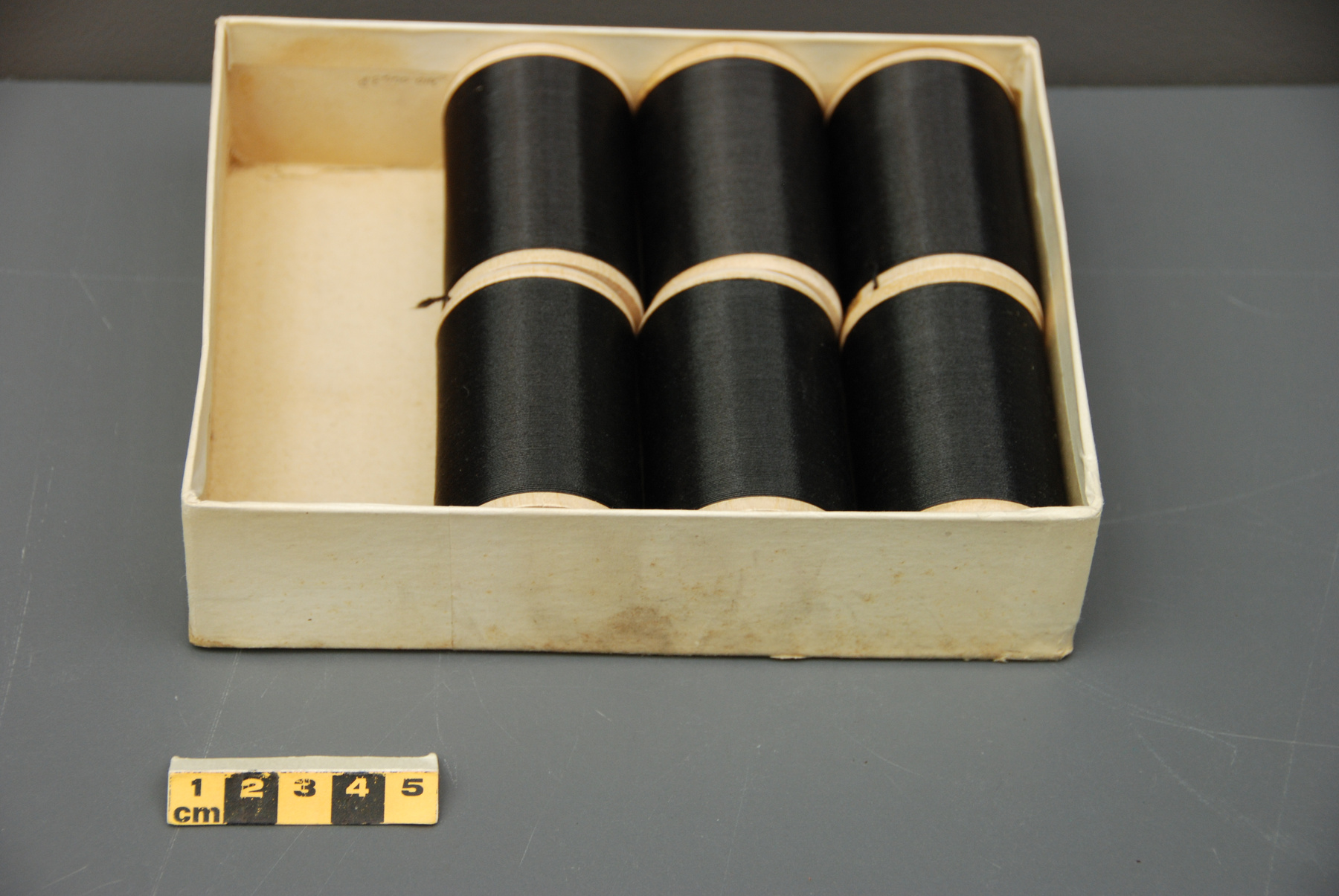

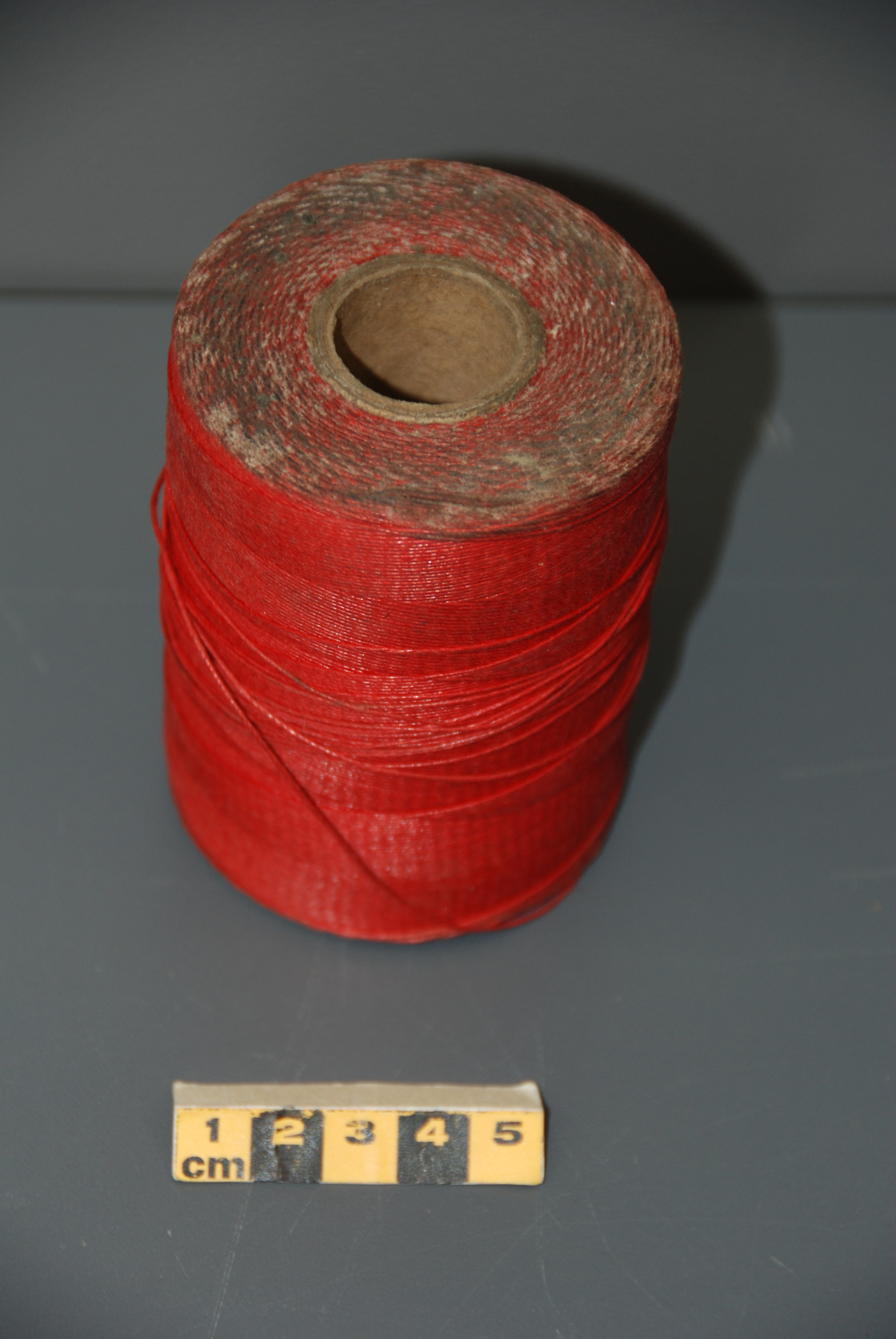

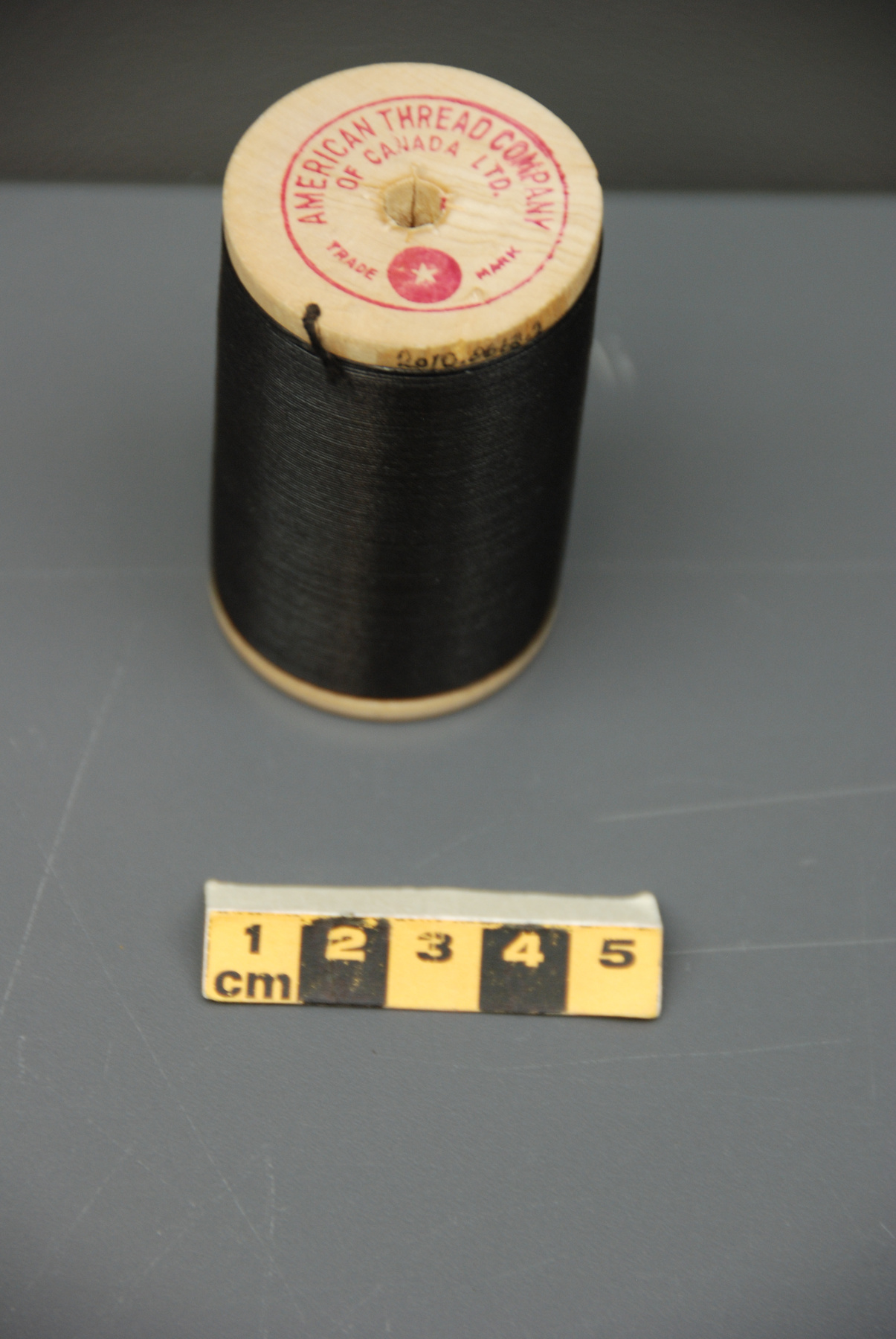

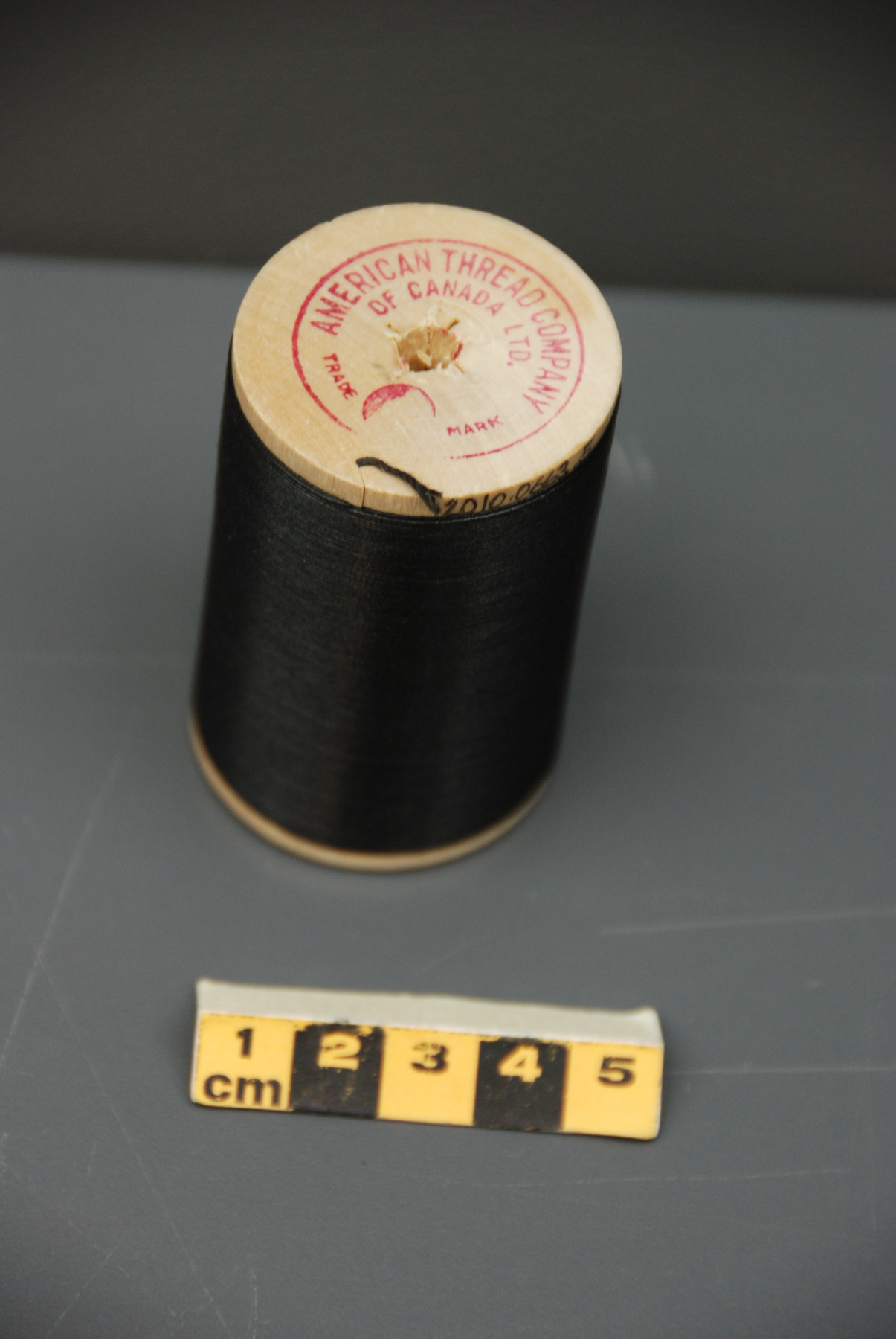

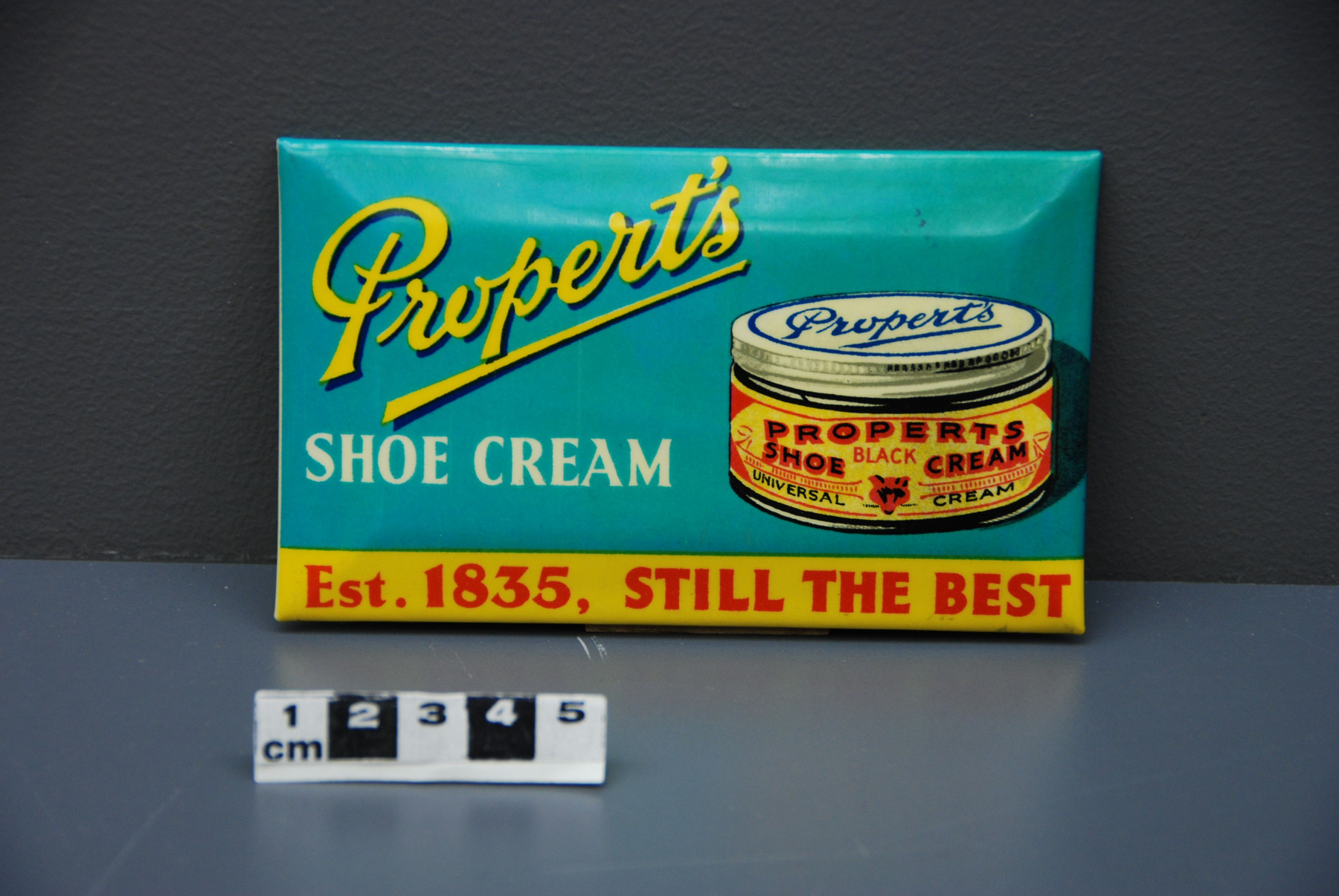

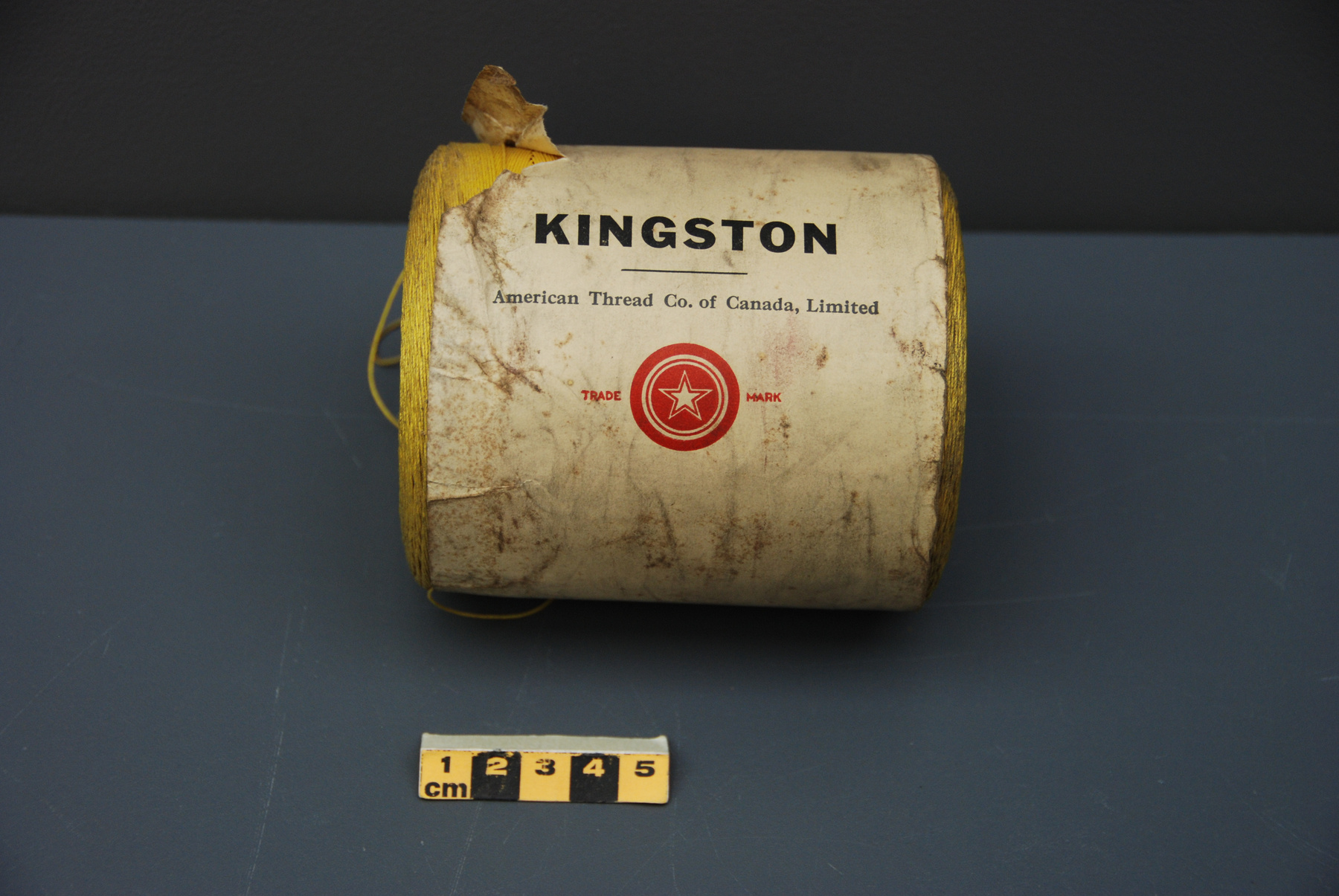

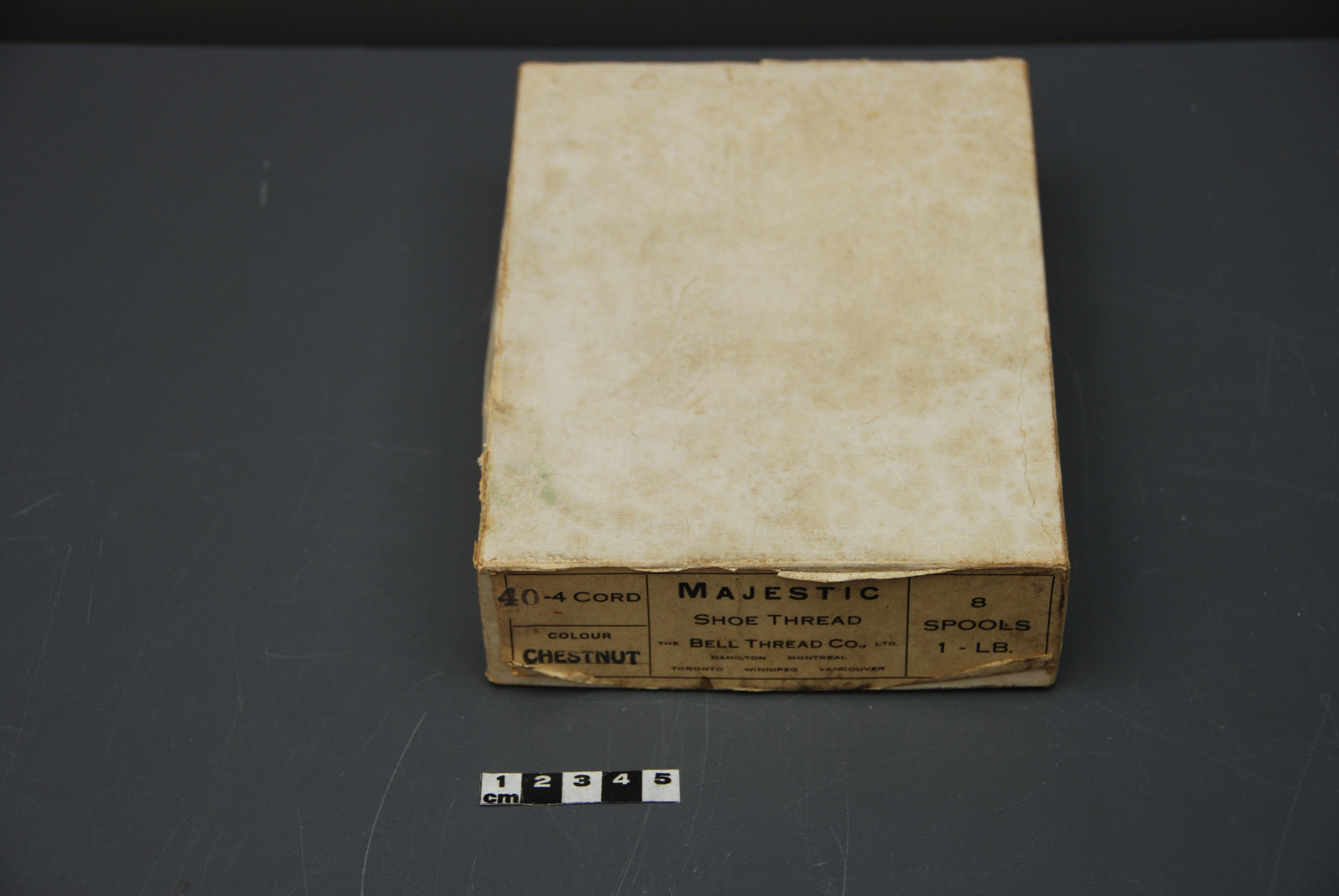

(Taken directly from the Acquisition Proposal. Context is for whole collection) This small shoe repair store was operated by Harry Samatas between 1932 and 1999 at 908 Queen St. in Toronto, Ont. Irakli (Harry) Naum Samatas (anglicized from Shamata) was born in Sinice, Albania on January 17, 1912. He received his high school education in Greece, where he also first learned to make shoes. He moved to Canada when he was 14. Mr. Samatas came to the country with his much older brother and cousins. Irakli started fixing shoes out of necessity in Canada, but was always very proud of the fact that he could actually make shoes. His wanted to establish a shoe making business, but it was very difficult for an immigrant to gather the means to start this kind of manufacturing company in Canada, where most of the shoemaking was done on a mass-production scale. Instead of a manufacturing company, Mr. Samatas opened his shoe repair store in 1932, when he was only 20 years old. In 1939 , Mr. Samatas travelled to Europe to be married; he and his wife, Sofia came back to Canada on board of the Conte di Savoia, on the ship’s last voyage from Italy before the WWII. Sofia Samatas never worked in the store or outside the home. Still, she spent time in the shoe store chatting with customers and keeping her husband company whenever she could. Mr. Samatas passed away on September 25, 1999, shortly after their 60th wedding anniversary. At the time of his death, he was a grandfather of six and a great-grandfather of two. Mr. Samatas kept the store open until his death. He didn't care if he had any customers - as long as the "old people" had a place to come and sit down for a chat, he was happy! The story of this shoe repair business carries interesting social history: it was a ‘replacement’ career - a small business that was less expensive to establish for an immigrant than a manufacturing company; the store was also a good example of a small local business that provided personal service to the local clientele and became a centre for a small community; and finally this donation documents a trade that is now disappearing. - Function

-

Unknown - Technical

-

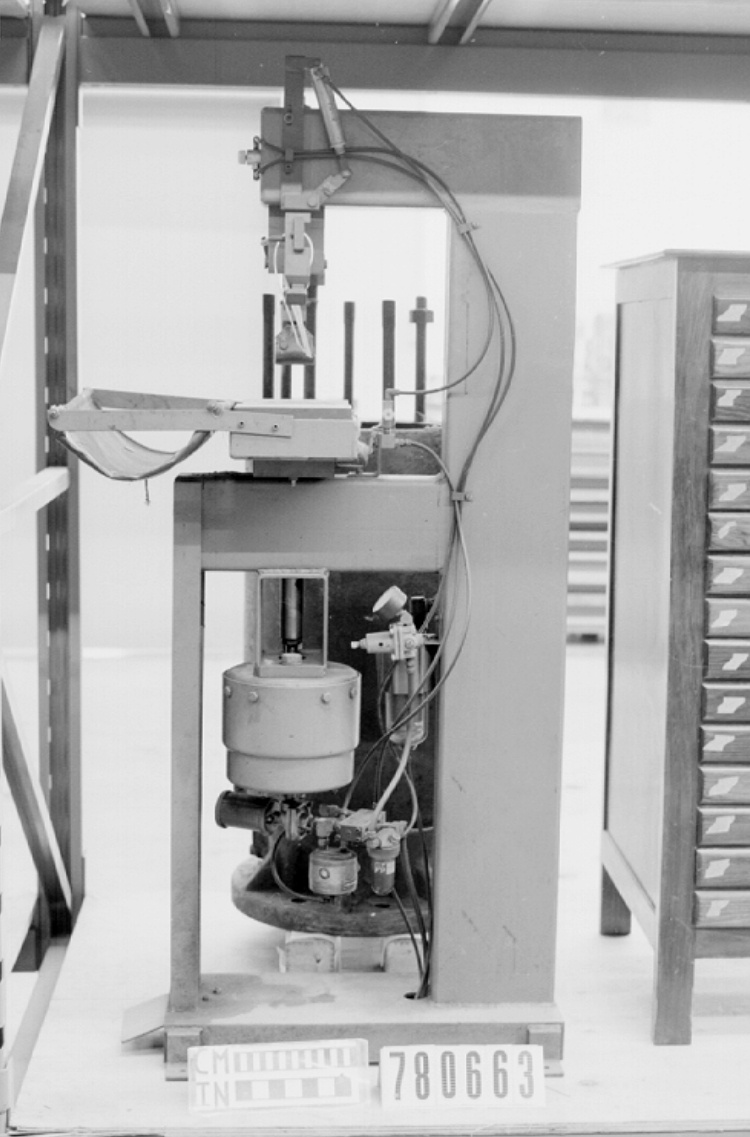

(Taken directly from the Acquisition Proposal. Context is for whole collection) There is very little written on shoe manufacturing and even less on shoe repairing: “The footwear industry is one of the oldest in Canada. The name of the first person in Canada to cobble a pair of shoes has not been recorded, but François Byssot of Pointe-Lévy, Québec, built the first tannery in 1668. Byssot was assisted by Jean TALON, who advanced the sum of 3268 livres from the royal coffers. The Compagnie des Indes occidentales contributed another 1500 livres. The first Canadian census (1666) revealed that 20 shoemakers served a population of 3215 inhabitants. The industry was required not only to look after the needs of the colony but also to equip a regiment of soldiers. Like cobblers all over the world, Canadian shoemakers used an awl, a curved knife, a needle and a wooden last. They set up shop in their own homes, employing 4 or 5 workers. Toward the middle of the 19th century, the introduction of machinery revolutionized the production of footwear. The sewing machine was adapted for stitching footwear components. Other devices were developed for cutting, cementing, nailing and vulcanizing parts of the shoe. Eventually, what had been a cottage craft became a sophisticated, highly mechanized factory industry. The 1871 census reported 4191 footwear-manufacturing establishments in Canada. Most were small shops which also did shoe repairs. With the advent of mechanized shoemaking equipment, many of these small manufacturers were forced out of business by the high capital cost of machinery and plant construction.” (From the Canadian Encyclopeadia) The entire small trade/cottage industry in Canada has been in decline since 1931. Even though the shoe repairing business belonged to the strongest sector within the industry (together with other ‘repair’ industries such as car repair, dressmaking, upholstery, etc.), it also declined from constituting 74% of cottage industries in 1931 to 58% in 1941. The trade rate was steady until 1951, and has been again in decline since that year. Arguably, the ‘repair’ occupations have been the strongest among the cottage industries because they involved personal contact between the service provider and the customer. The face-to-face encounter between the provider and the customer, so evident in the story of Harry’s Shoe Repairing, is necessary for the survival of a small trade. The industries that did not require such a contact had the fastest rate of decline, and were often taken over by large manufacturers. The mechanization of the footwear industry took place between the 1850 and 1900s. The processes were transferred to the footwear industry from sewing and leatherwork, for example sewing machines were adapted into stitchers; skiving machines that bevel edges of shoe parts to prevent ridges at stitched, cemented, or folded edges are very similar to machines used in leatherwork. After 1900 almost all shoes in North America were mass-produced. Small, family owned businesses within the footwear industry focused on shoe repairing. The repair work involved a combination of hand tools and machine tools. Individual pieces of equipment offered to the Museum represent the tools and the machinery, which persisted with little changes from 1930s till 1990s. The equipment presents all phases of shoe repair from stitching to finishing. - Area Notes

-

Unknown

Details

- Markings

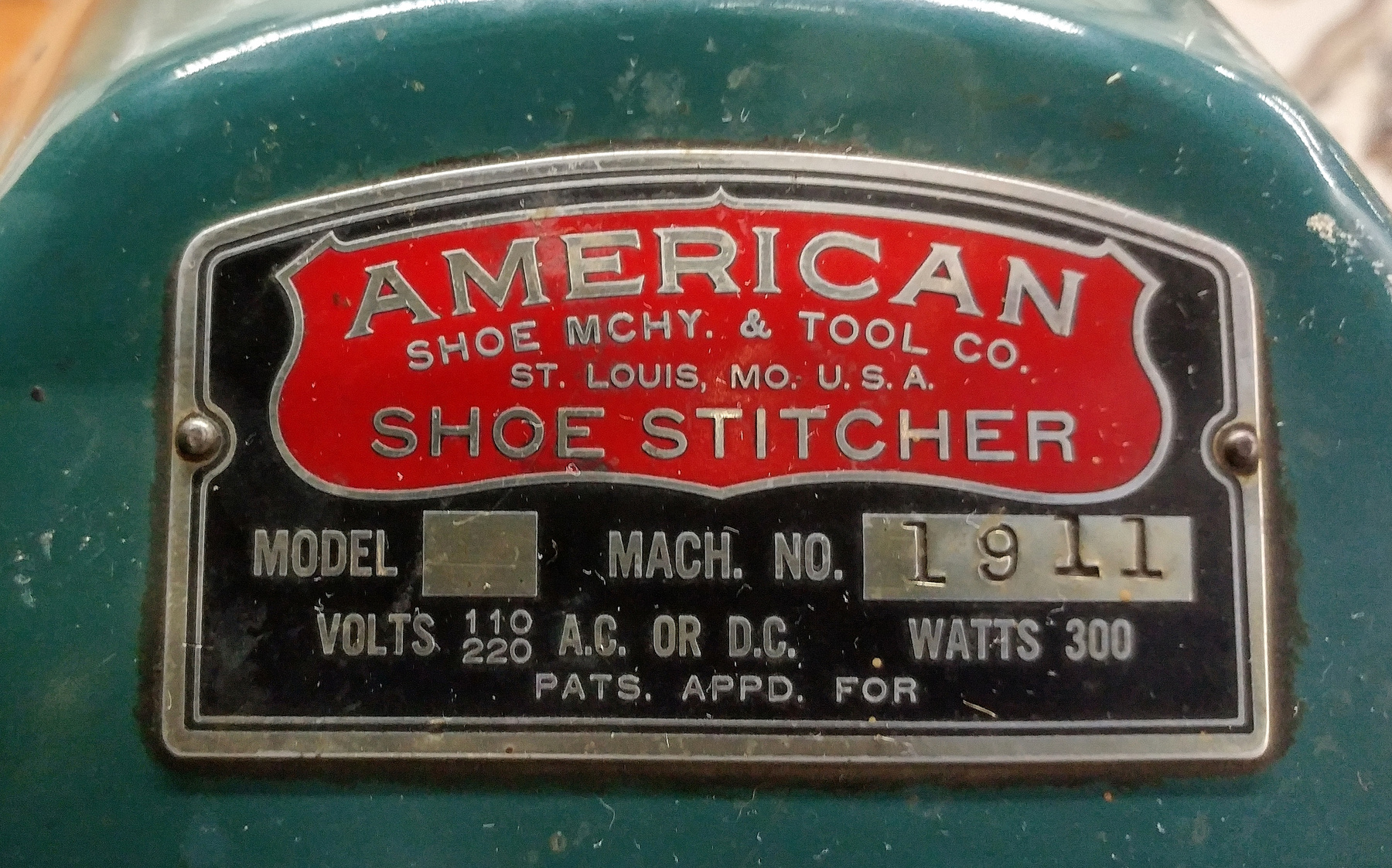

- On the proper front, on a large metal cover at the proper top: "AMERICAN/ ST. LOUIS"/ On the body of the base on the proper front: "MADE IN USA/ AMERICAN/ ST. LOUIS/ MODEL-B"/ Down the proper right side: "AMERICAN"/ On the control panel on the proper left: "HEAT/ MOTOR/ B-13-A1"/ On the mfr. plate on top of the control panel: "AMERICAN/ SHOE MCHY. & TOOL CO./ ST. LOUIS, MO. U.S.A./ SHOE STITCHER/ MODEL/ MACH. NO. 1911/ VOLTS 110/ 220 A.C. OR D.C./ WATTS 300/ PATS. APPD. FOR"/ On a small switch on the proper left side: "HIGH/ LOW/ THERMOSTAT CONTROL"/ On various points on the proper back: "B-13-A2"/ "B-12-14"/ "B-12-13"

- Missing

- Appears complete

- Finish

- Predominantly green finished metal machine with silver-coloured metal wheels and parts, a brown coloured metal lamp cover, black finshed panels on the proper back and some black parts on the proper front.

- Decoration

- N/A

CITE THIS OBJECT

If you choose to share our information about this collection object, please cite:

American Shoe Machinery & Tool Co., Stitcher, Unknown Date, Artifact no. 2008.1637, Ingenium – Canada’s Museums of Science and Innovation, http://collection.ingeniumcanada.org/en/id/2008.1637.001/

FEEDBACK

Submit a question or comment about this artifact.

More Like This