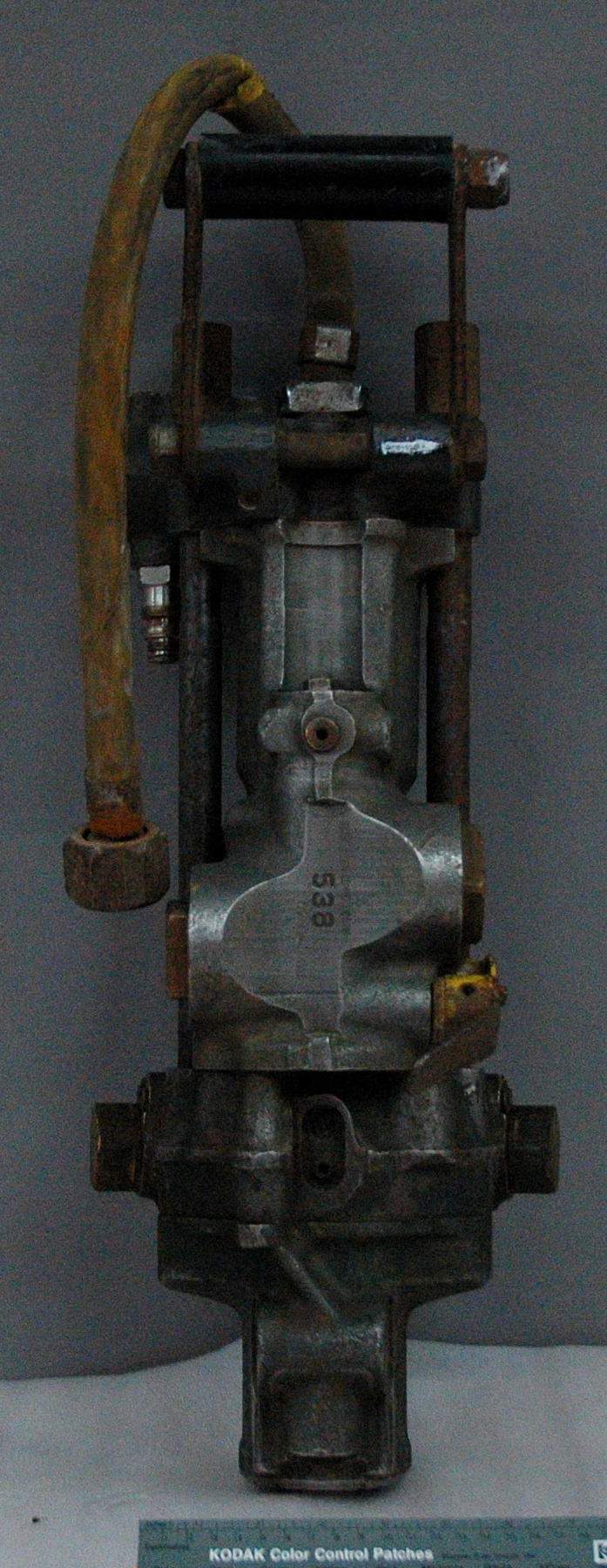

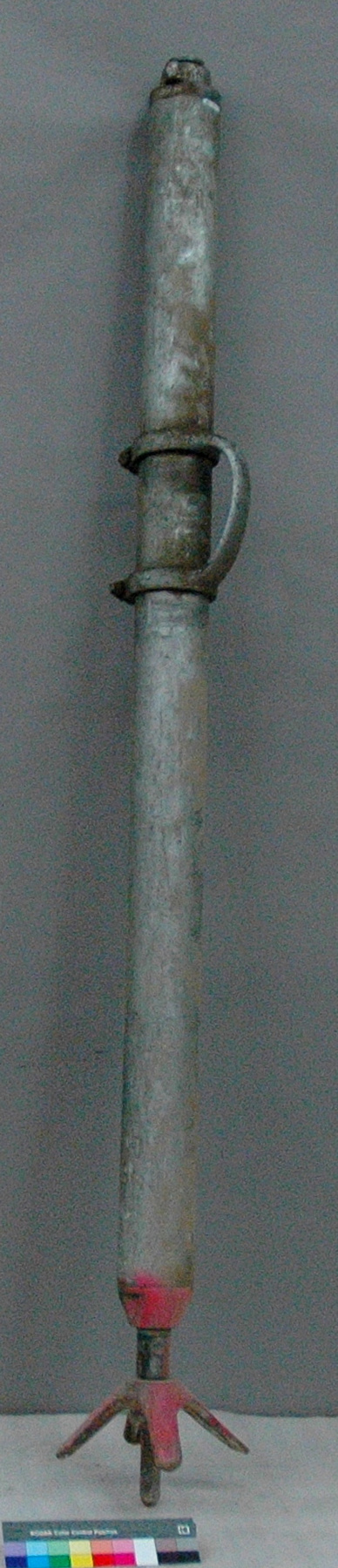

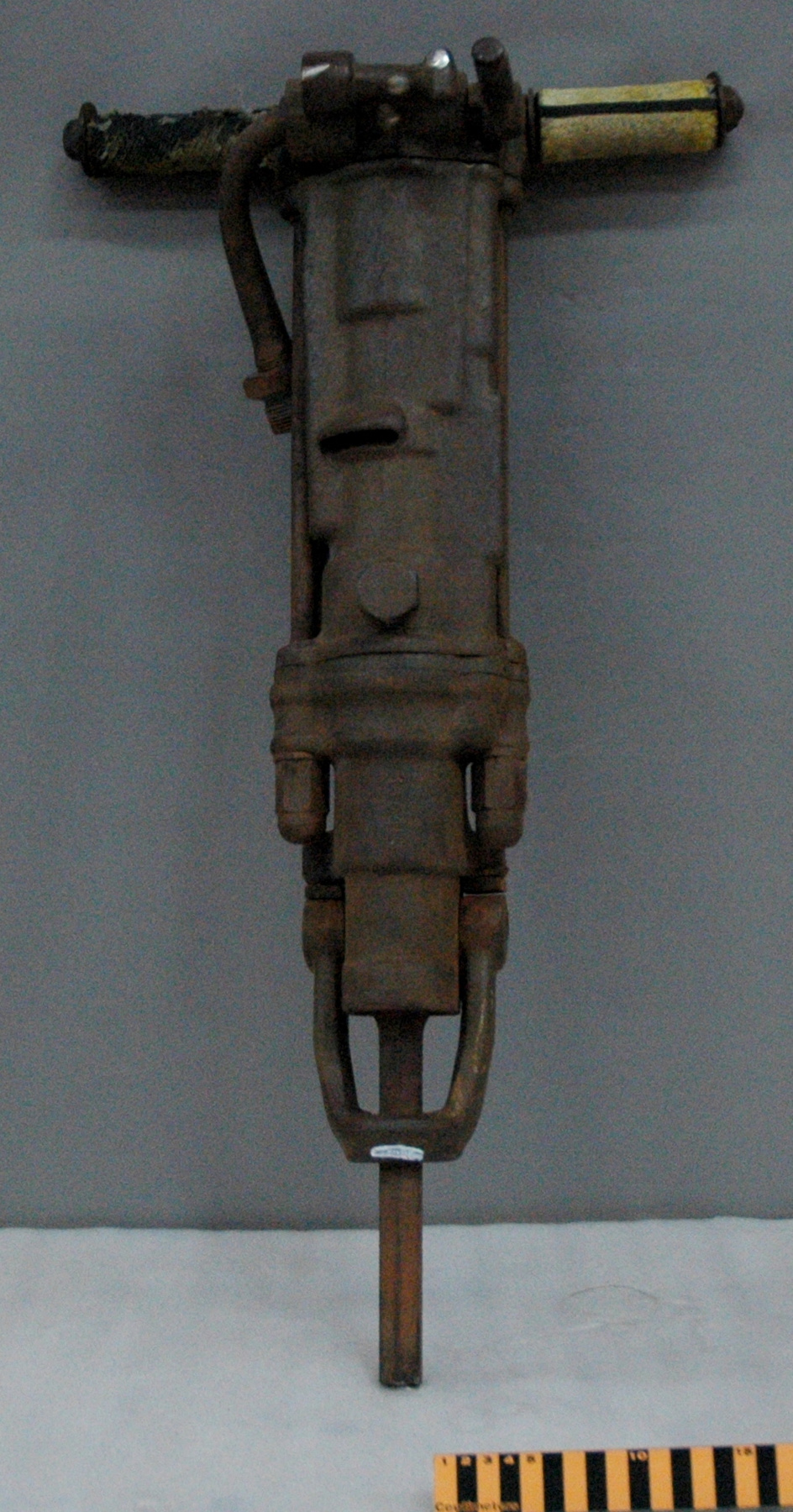

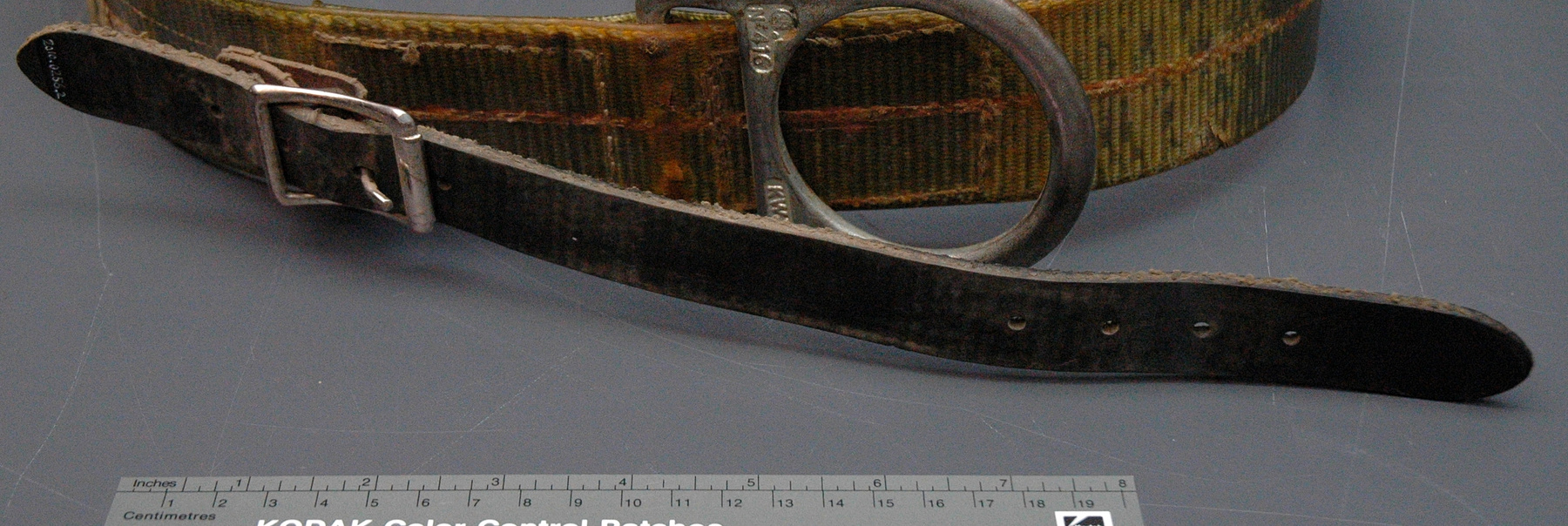

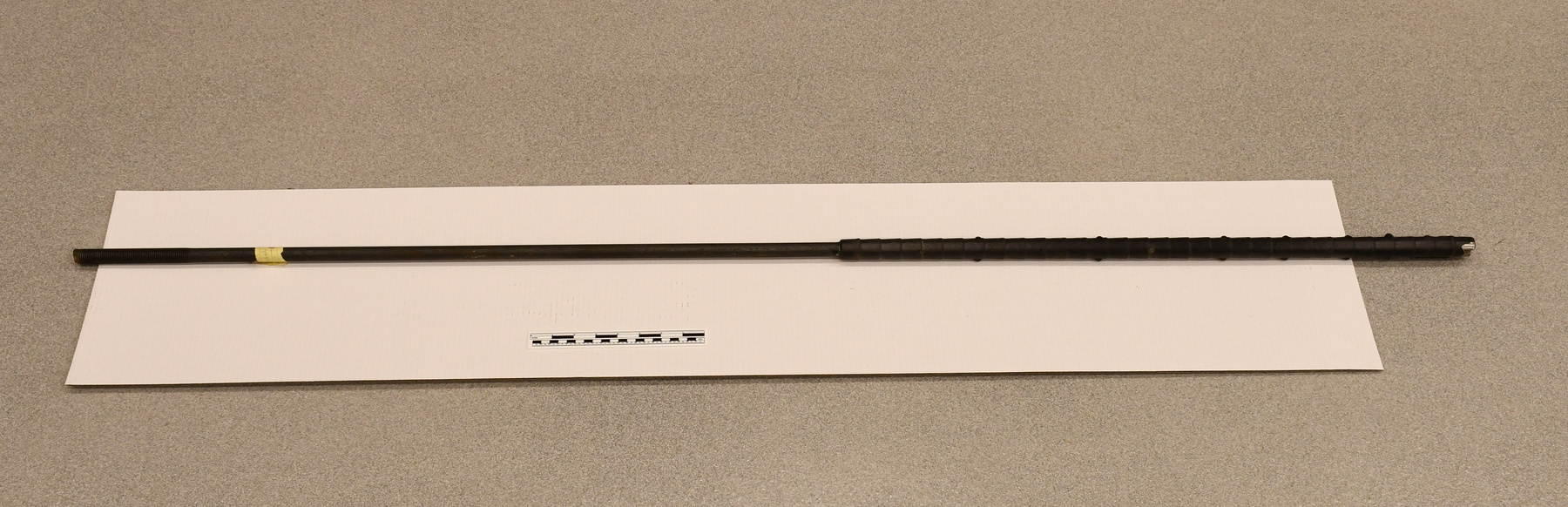

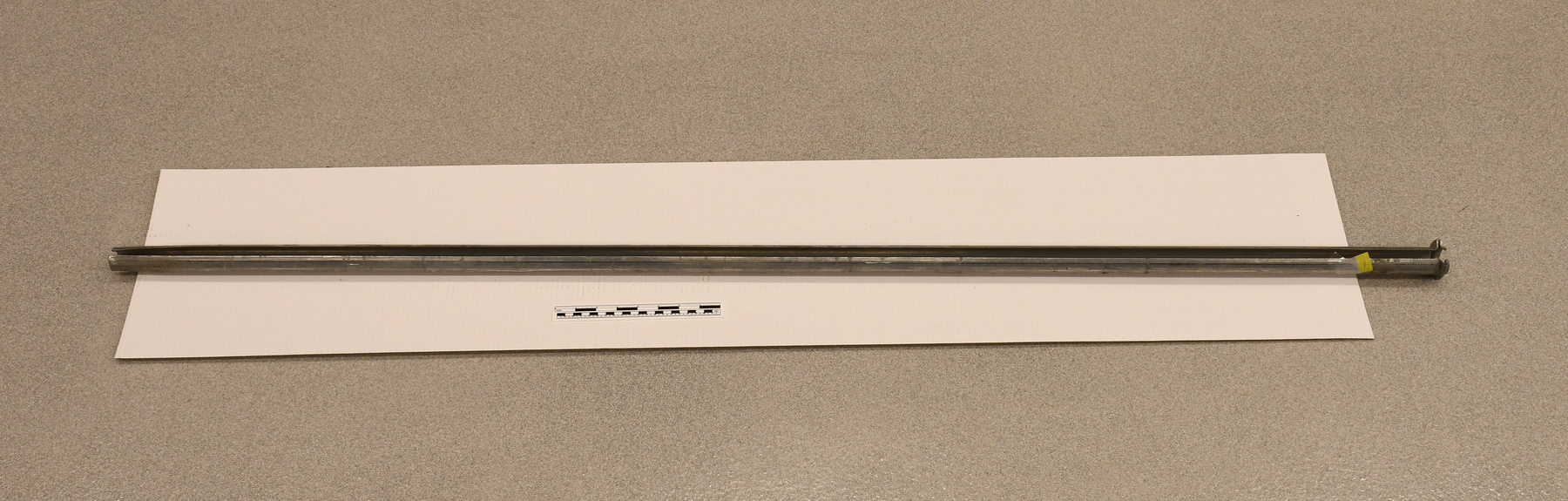

Bit, mining drill & rod

Use this image

Can I reuse this image without permission? Yes

Object images on the Ingenium Collection’s portal have the following Creative Commons license:

Copyright Ingenium / CC BY-NC-ND (Attribution-NonCommercial 4.0 International (CC BY-NC 4.0)

ATTRIBUTE THIS IMAGE

Ingenium,

2010.0269.004

Permalink:

Ingenium is releasing this image under the Creative Commons licensing framework, and encourages downloading and reuse for non-commercial purposes. Please acknowledge Ingenium and cite the artifact number.

DOWNLOAD IMAGEPURCHASE THIS IMAGE

This image is free for non-commercial use.

For commercial use, please consult our Reproduction Fees and contact us to purchase the image.

- OBJECT TYPE

- N/A

- DATE

- 1976

- ARTIFACT NUMBER

- 2010.0269.004

- MANUFACTURER

- Ingersoll Rand

- MODEL

- Unknown

- LOCATION

- South Africa

More Information

General Information

- Serial #

- N/A

- Part Number

- 4

- Total Parts

- 4

- AKA

- N/A

- Patents

- N/A

- General Description

- Dull silver metal [steel ?].

Dimensions

Note: These reflect the general size for storage and are not necessarily representative of the object's true dimensions.

- Length

- 172.0 cm

- Width

- N/A

- Height

- N/A

- Thickness

- N/A

- Weight

- N/A

- Diameter

- 4.0 cm

- Volume

- N/A

Lexicon

- Group

- Mining and Metallurgy

- Category

- Mineral extraction

- Sub-Category

- N/A

Manufacturer

- AKA

- Ingersoll Rand

- Country

- South Africa

- State/Province

- Unknown

- City

- Unknown

Context

- Country

- Canada

- State/Province

- Quebec

- Period

- This drill was used 1995+; possibly used as early as 1976.

- Canada

-

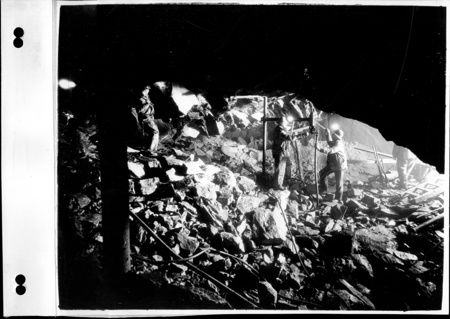

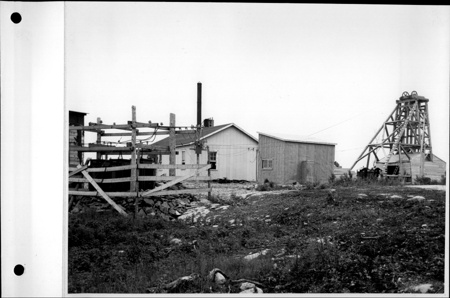

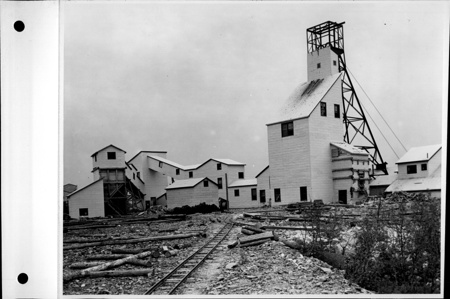

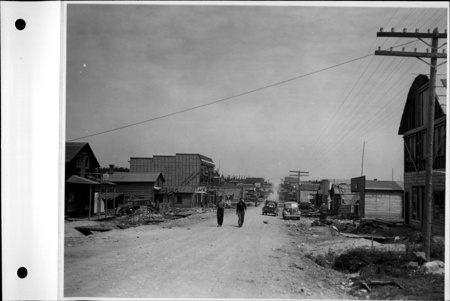

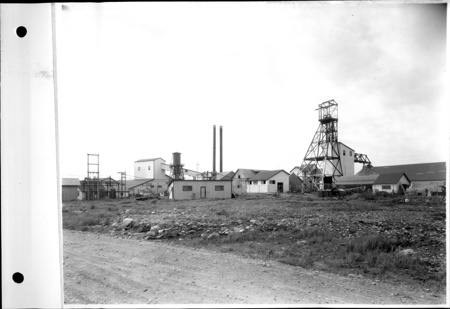

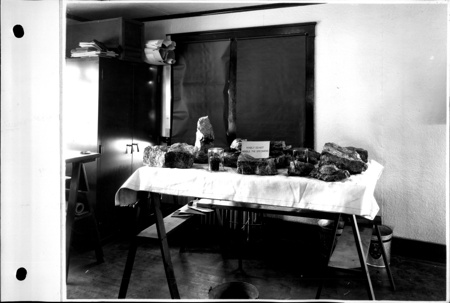

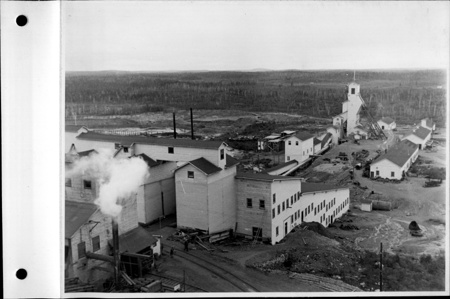

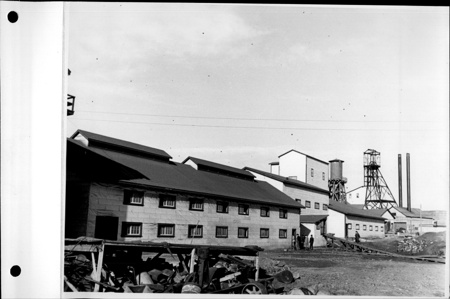

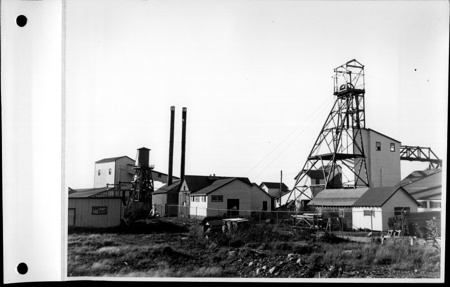

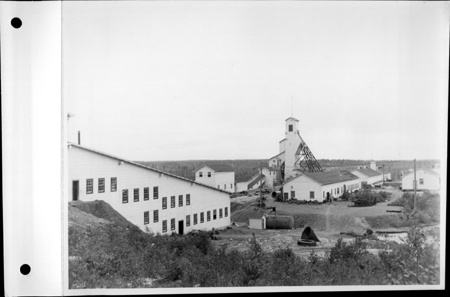

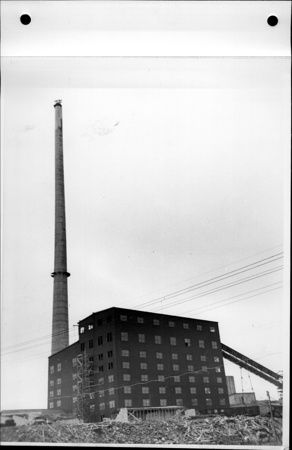

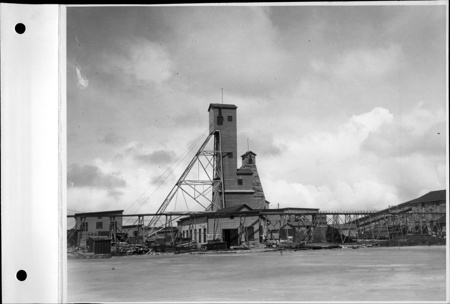

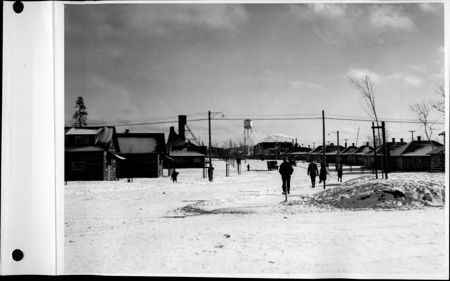

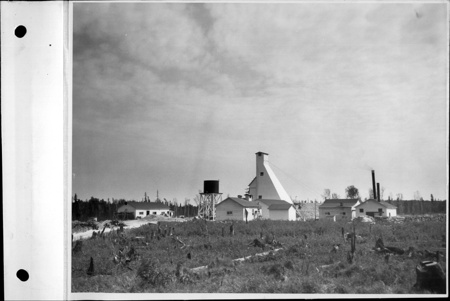

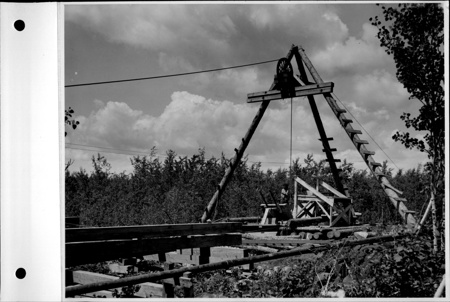

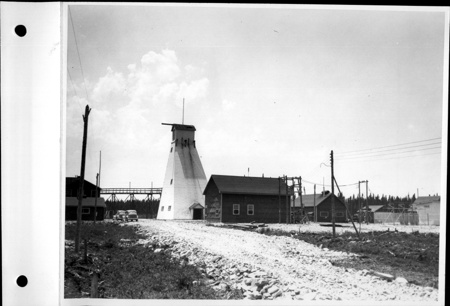

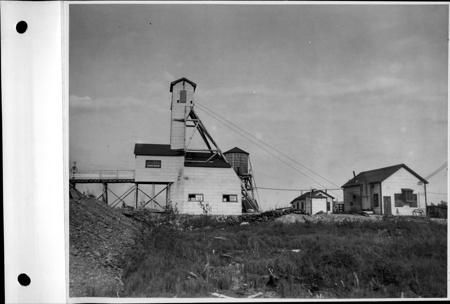

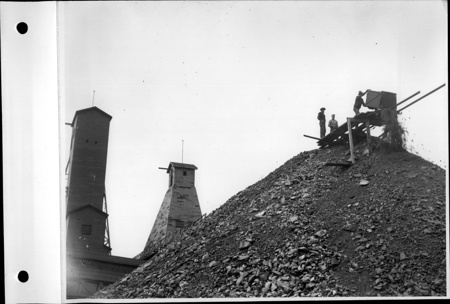

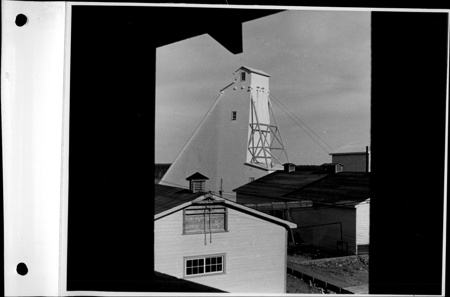

The CANMET-MMSL EXPERIMENTAL MINE in Val-d'Or, Quebec, was established in 1991 in response to Canadian and local mining industry needs for an increased emphasis on applied research. The former Beacon Gold Mine is an underground facility for in-situ testing and research in a true mining environment. The Experimental Mine is also available for individual companies to test equipment or for training purposes on a contract basis. CANMET-MMSL scientists at the Experimental Mine also offer a range of services to the local mining industry. The equipment suggested for acquisition represents the testing done by CANMET scientists. The mine comprises a unique underground hard rock testing site with an access ramp and five underground levels. There are two interconnected gold mines at this site. The earlier mine, Le Roy was opened from 1931-1932. It was operated by Le Roy Gold Mines Ltd. The Beacon II was open in mid-1980s and was owned by Mines Aurizon Ltd. There are over 2500 metres of drifts, plus raises and secondary openings and shrinkage stopes. Val d’Or area is very important to Canadian mining since gold was discovered there in 1923. Gold, copper, zinc and lead are still mined there today. Val d’Or had been and home to many mining companies such as Bourlamaque, Siscoe, Sigma, Sullivan, Lamaque, Osisco and Northern Star Mining. The history of the town reflects the region’s economic dependence on mining. [Ref. 1] - Function

-

Cutting head, used to drill through rock surface. - Technical

-

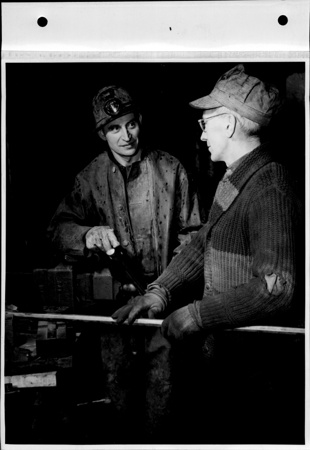

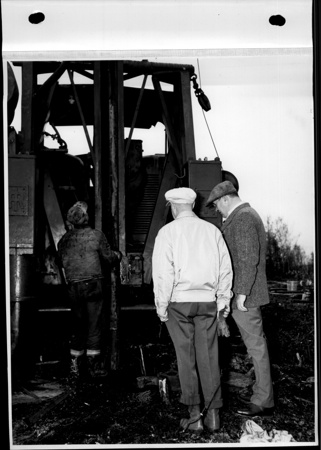

This drill was used in one of the South African platinum mines (most likely belonging to Anglo American Co.). Ingersoll Rand dominates the market for drilling technologies. The history of the company goes back to 1871. Canmet purchased the drill from South Africa to experiment in adaptation of water drill technologies to Canadian conditions. This is the 1st prototype of the hydraulic rock drill that led to the development of Candrill. The hydraulic drill is better in many ways than the pneumatic drill. It can double the penetration rate of the air drill; reduces noise by at least 10 - 15 decibels; vibrations are also reduced. Fumes are eliminated – a considerable improvement for an underground operation; dust is reduced. Also the energy efficiency is increased by 30 to 40 percent. Canmet looked at the ergonomics of that machine. The drill has sharp features that may hurt a miner. In SA three miners operated the drill: two controlled a bar attached to the front of the drill, and the third miner held the leg. In Canada, only one miner operates a drill for greater workforce efficiency. Slopes in SA mines are much smaller (3 feet) than in Canadian mines (8 feet) and exploitation is done at a different angle. A Canadian miner holds the drill in a very different way than SA miners. Canmet experimented with the controls, the attachments, and the centre of gravity of the machine to make it operable by one person at an appropriate angle. In SA water from the drill was sprayed to cool the mine, in Canada mines are not as hot, and the water was recycled. The drill operates at 3000 psi (pounds per square inch) and uses 6 liters of water per minute. SA mines are deeper then Canadian and the drill used water head, but in Canada it had to be connected to a water pump. This specific drill did not work well in Canadian conditions. It was too heavy, but it led the way to the second prototype and finally to the Candrill. [Ref. 1] - Area Notes

-

Unknown

Details

- Markings

- None evident.

- Missing

- Unknown.

- Finish

- Dull silver metal [steel ?].

- Decoration

- N/A

CITE THIS OBJECT

If you choose to share our information about this collection object, please cite:

Ingersoll Rand, Bit, mining drill & rod, circa 1976, Artifact no. 2010.0269, Ingenium – Canada’s Museums of Science and Innovation, http://collection.ingeniumcanada.org/en/id/2010.0269.004/

FEEDBACK

Submit a question or comment about this artifact.

More Like This