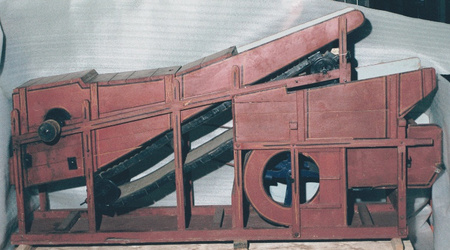

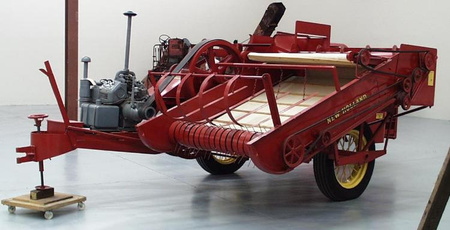

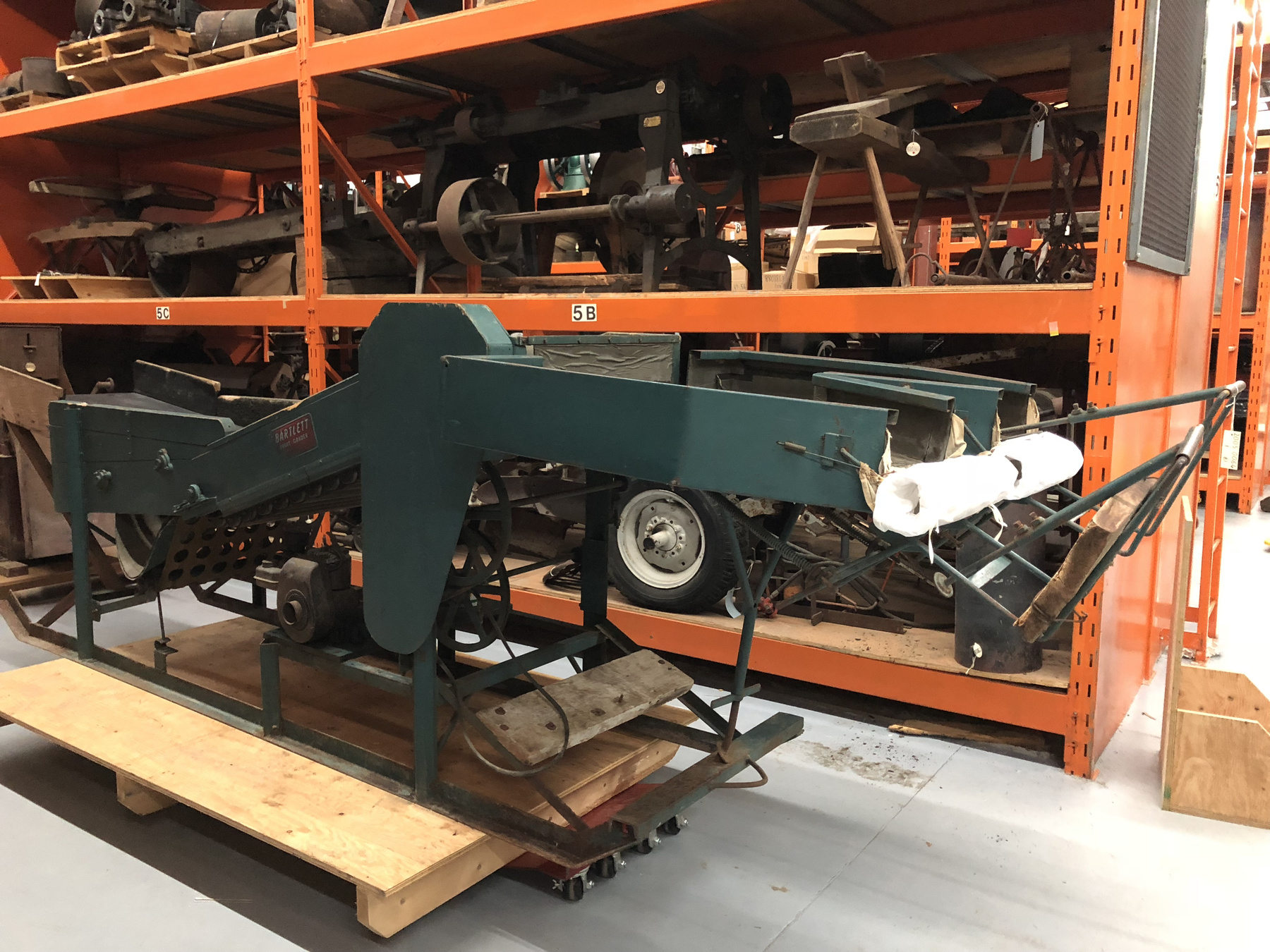

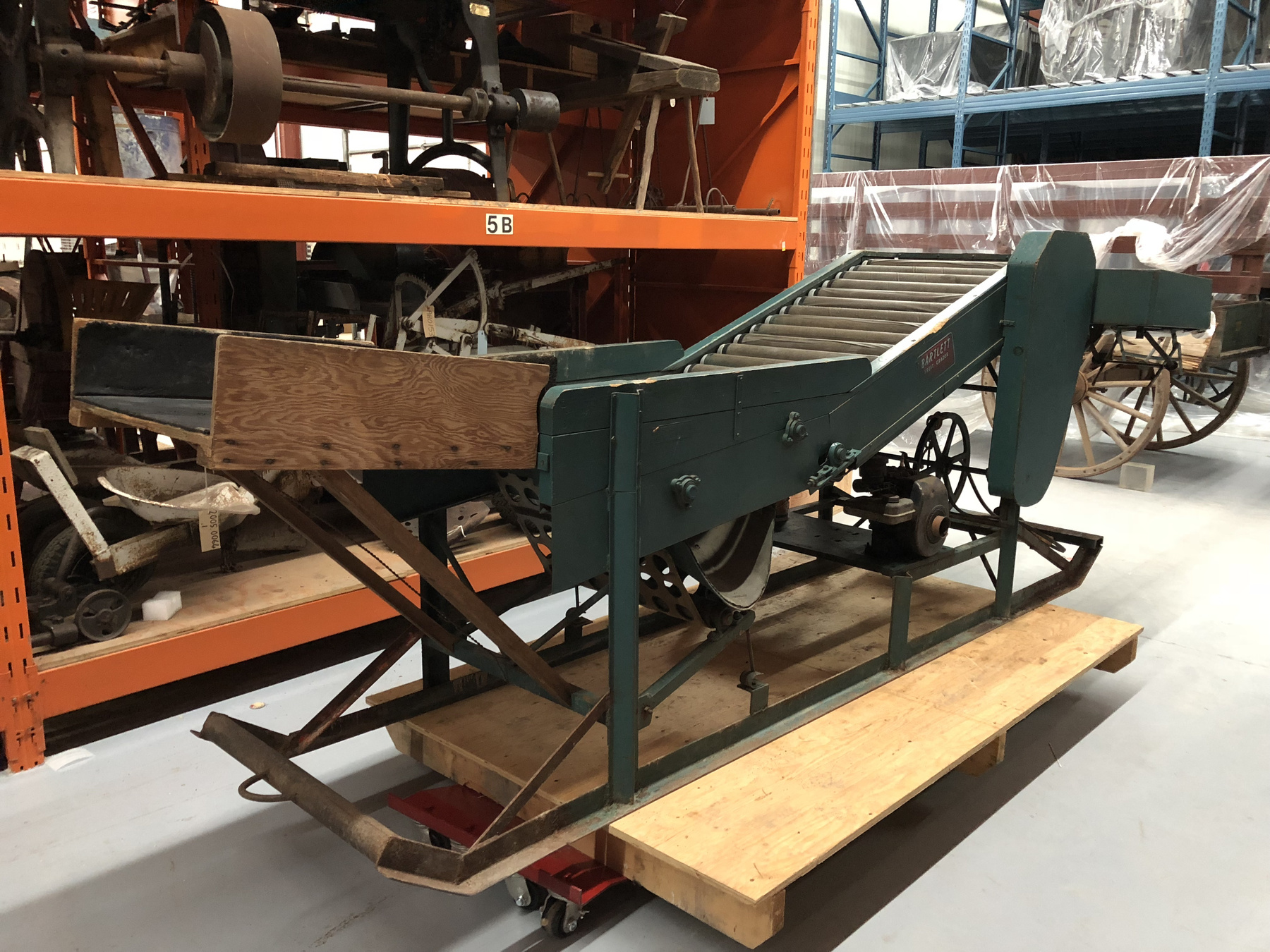

Trieur de fruit

Utiliser cette image

Puis-je réutiliser cette image sans autorisation? Oui

Les images sur le portail de la collection d’Ingenium ont la licence Creative Commons suivante :

Copyright Ingenium / CC BY-NC-ND (Attribution-NonCommercial 4.0 International (CC BY-NC 4.0)

ATTRIBUER CETTE IMAGE

Ingenium,

2005.0064.001

Permalien: https://files.ingeniumcanada.org/items/coll/253/050/2005-0064-001-aa-cs_thumb.jpeg

Ingenium diffuse cette image sous le cadre de licence Creative Commons et encourage son téléchargement et sa réutilisation à des fins non commerciales. Veuillez mentionner Ingenium et citer le numéro de l’artefact.

TÉLÉCHARGER L’IMAGEACHETER CETTE IMAGE

Cette image peut être utilisée gratuitement pour des fins non commerciales.

Pour un usage commercial, veuillez consulter nos frais de reproduction et communiquer avec nous pour acheter l’image.

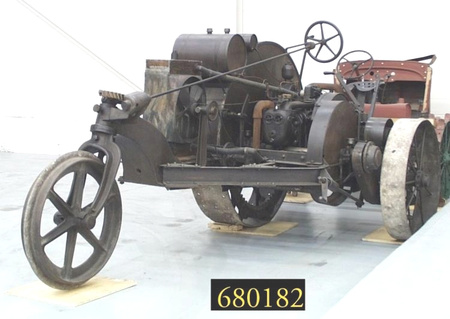

- TYPE D’OBJET

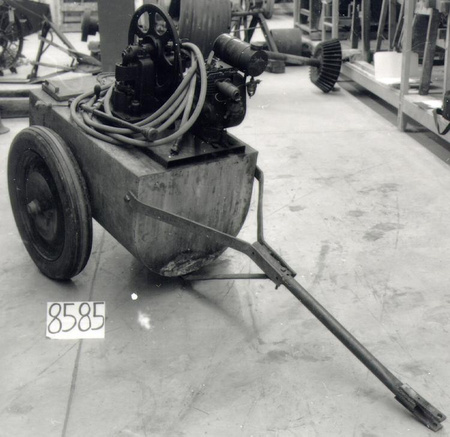

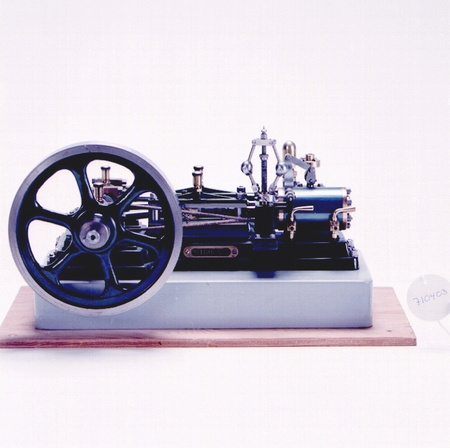

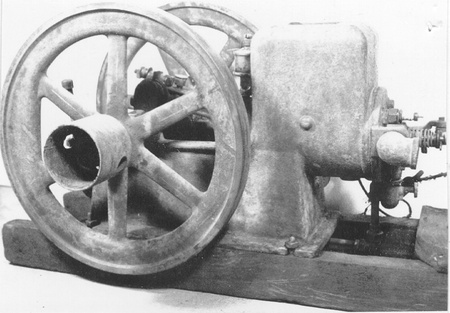

- apple/gasoline engine powered

- DATE

- 1948–1950

- NUMÉRO DE L’ARTEFACT

- 2005.0064.001

- FABRICANT

- Bartlett Mfg. Co. Ltd.

- MODÈLE

- Inconnu

- EMPLACEMENT

- Beamsville, Ontario, Canada

Plus d’information

Renseignements généraux

- Nº de série

- S/O

- Nº de partie

- 1

- Nombre total de parties

- 1

- Ou

- S/O

- Brevets

- S/O

- Description générale

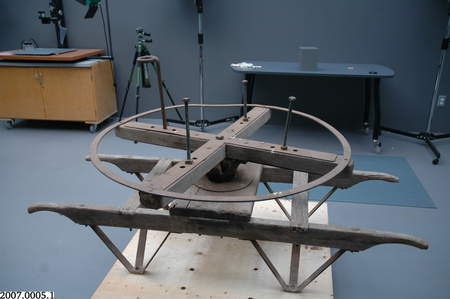

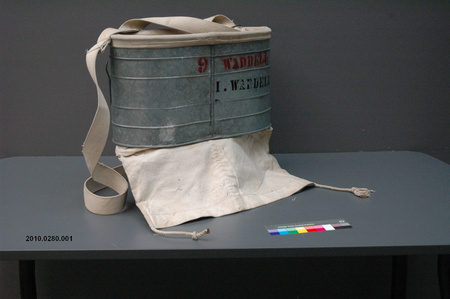

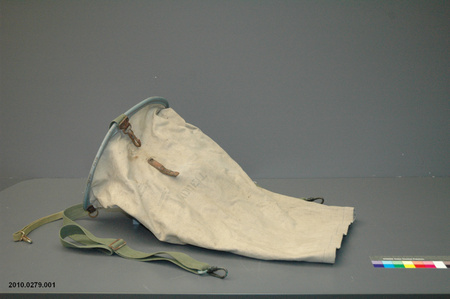

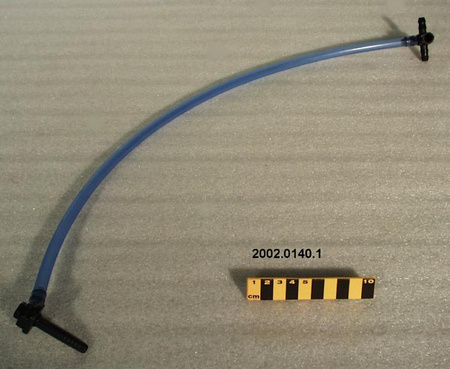

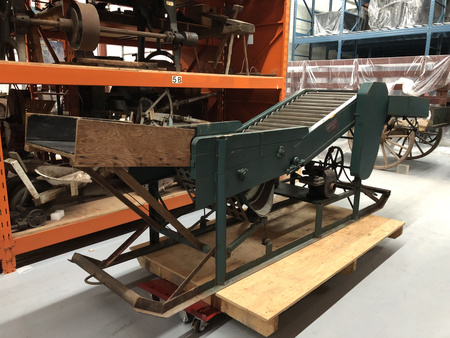

- wood and metal frame on metal runners (not original)/ wood and metal working parts/ synthetic and/or rubber conveyor belts, rollers, parts/ two fabric sacks attached to chutes at back end

Dimensions

Remarque : Cette information reflète la taille générale pour l’entreposage et ne représente pas nécessairement les véritables dimensions de l’objet.

- Longueur

- 332,0 cm

- Largeur

- 121,0 cm

- Hauteur

- 128,0 cm

- Épaisseur

- S/O

- Poids

- S/O

- Diamètre

- S/O

- Volume

- S/O

Lexique

- Groupe

- Agriculture

- Catégorie

- Traitement de récolte

- Sous-catégorie

- S/O

Fabricant

- Ou

- Bartlett

- Pays

- Canada

- État/province

- Ontario

- Ville

- Beamsville

Contexte

- Pays

- Canada

- État/province

- Ontario

- Période

- circa 1950+

- Canada

-

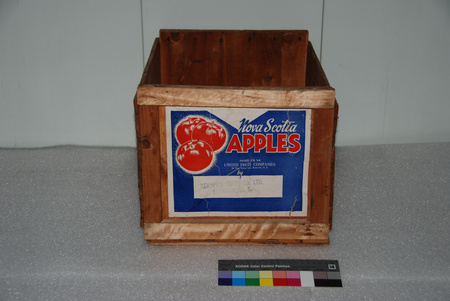

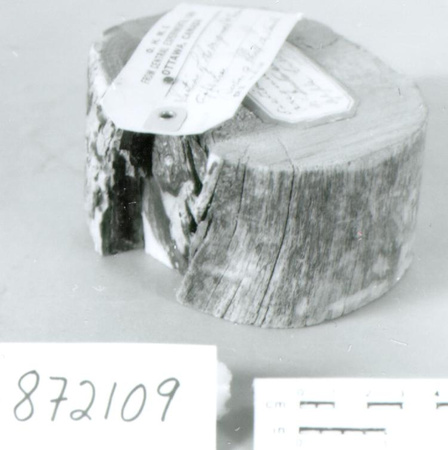

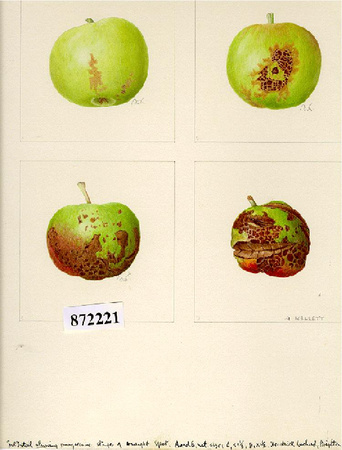

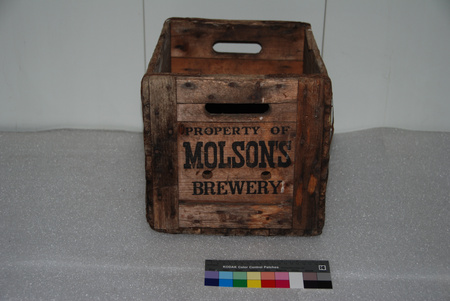

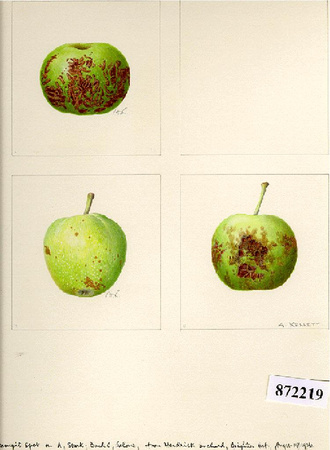

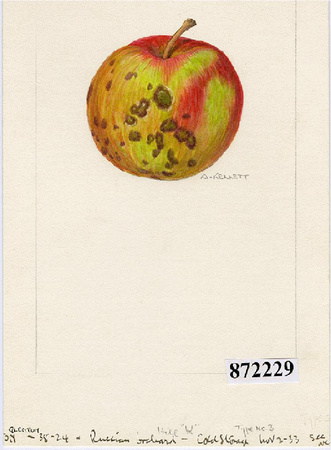

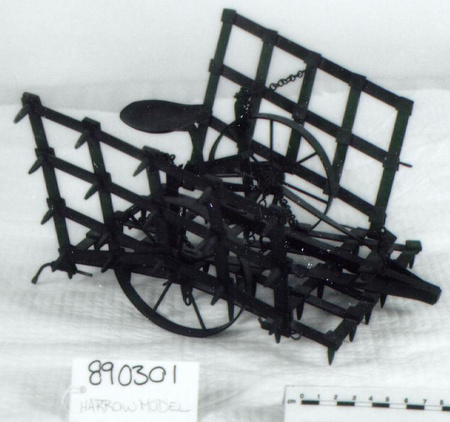

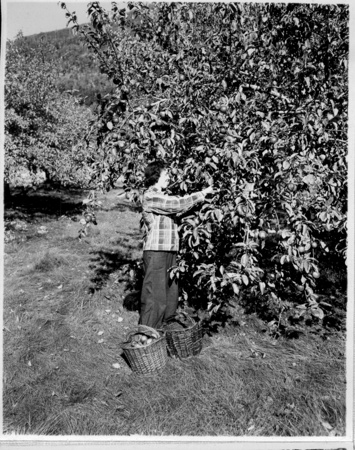

This piece of equipment was acquired from the Estate of Mr. Keith Clancy. Of Stirling, ON. The Clancy family has farmed outside Stirling since 1880 and according to Karen Atkinson, Mr. Clancy's daughter, they put in an orchard around 1900. From that time until the early 1990s the family grew apples and Pears as well as running a mixed farming operation. From about 1900 to 1930 they hauled their apples into the railway station in Stirling for shipping to markets in Toronto. After that point, they sold apples at the farmer's market in Stirling as well as at the farm gate. By the 1940s, they had three acres in apples and one acre in pears, growing mostly Macs, Spys and Bartletts. As the eldest male, Keith Clancy took over the farm from his parents and lived on the property until his death in 2003. His children decided to sell the farm equipment and to rent the land to a neighbouring farmer. Geographically the Clancy farm is located in the same soil belt that extends away from Lake Ontario, but at the extreme north end of the belt for commercial orchard agriculture. The moderating effect is also a factor in orchard development. The farm's relative remoteness has meant that farm gate sales and bulk sales to cider mills closer to the 401 are the only means of selling the year's crop. According to Mrs. Atkinson, by late in her father's life the majority of the Clancy`s apples were being eliminated during the grading process and fated to be made into cider rather than sold for eating. The cost of sprays and labour to pick what were only cider apples did not make economic sense. According to Mrs. Atkinson, her father bought this grader sometime between the end of WWII and 1950. Each year it was brought out of storage in a shed where it was stored with the rest of the orchard equipment to an area between the orchard and the farm lane so it could be close to the picking, sorting and packing operation. In the mid 1960s the grader was mounted on a metal skid base so it could be moved by tractor. Sometime in the last twenty years, it was given a coat of green spray paint and a plywood extension was built for the feed end. En savoir plus - Fonction

-

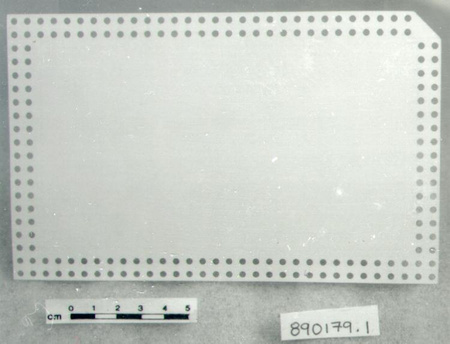

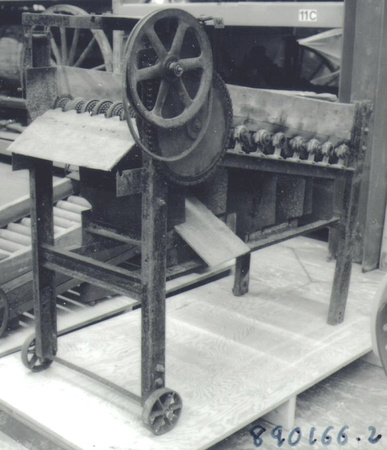

A device for sorting or grading apples by size. - Technique

-

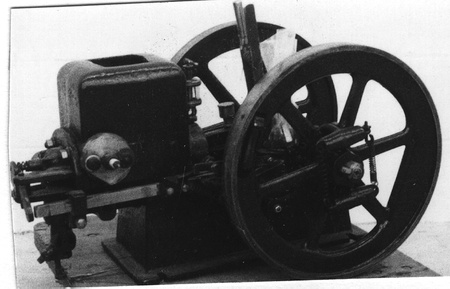

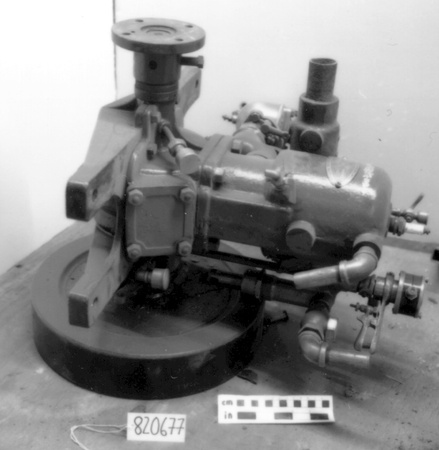

An example of a mechanical apple sorter or eliminator. The size of an apple is affected by a number of factors including variety, pollination levels, rainfall, position on the tree and pests. When marketing eating apples, orchardists need a means of sorting the produce to eliminate fruit that does not meet the accepted standards of size. In small operations of the late 19th century, apples were placed on a table and sorted by size, a labour intensive operation. Manual apple eliminators first came into use in Ontario (and probably Quebec, the Maritimes and BC) about 1900. The apples were placed on a slightly inclined surface and rolled down over an area perforated with holes; the size of these holes. The size of these holes was determined by orchardist association standards and apples that were too small fell through the holes and were eliminated. That fruit was usually ground and crushed to make cider. The development of small gasoline engines made it possible to mechanize and speed the sorting process, exemplified by this Bartlett fruit grader. Apples removed from bulk boxes are placed on the lower end of the grader, a series of pulleys under the table drive the moveable belt that brings the apples to the sorting belt which has wholes through which the cull apples would fall. The good apples proceeded up a series of padded rollers and were placed in the appropriate baskets. This device could process a larger quantity of apples than its manual predecessor and only required semi-skilled labour to fill the apple baskets. In the 1950`s orchardists would have set up a number of graders in a row in the orchard or near the packing house. Today large aluminum units powered by electric motors that sort and wash the apples are the industry standard. Bartlett Manufacturing Company established a manufacturing and supply facility in Detroit, MI in 1914 and shortly thereafter set up a manufacturing and distribution warehouse in Vineland to supply Ontario`s orchard industry with all types of orchard and vineyard equipment. In the early 1980s, the company moved its facilities to Detroit and changed its name slightly. En savoir plus - Notes sur la région

-

Inconnu

Détails

- Marques

- partially over-painted red label on side reads ‘BARTLETT/ FRUIT GRADER/ Manufactured By/ BARTLETT MANUFACTURING CO., LTD./ BEAMSVILLE - ONTARIO - CANADA'/ label on engine reads ‘4/ CYCLE/ BRIGGS & STRATTON/ MILWAUKEE, WIS, USA/ GASOLINE ENGINE

- Manque

- unknown

- Fini

- body painted teal blue (not original/ some unfinished wood and metal pieces and some with finish obscured by weathering or corrosion

- Décoration

- S/O

FAIRE RÉFÉRENCE À CET OBJET

Si vous souhaitez publier de l’information sur cet objet de collection, veuillez indiquer ce qui suit :

Bartlett Mfg. Co. Ltd., Trieur de fruit, vers 1948–1950, Numéro de l'artefact 2005.0064, Ingenium - Musées des sciences et de l'innovation du Canada, http://collection.ingeniumcanada.org/fr/id/2005.0064.001/

RÉTROACTION

Envoyer une question ou un commentaire sur cet artefact.

Plus comme ceci