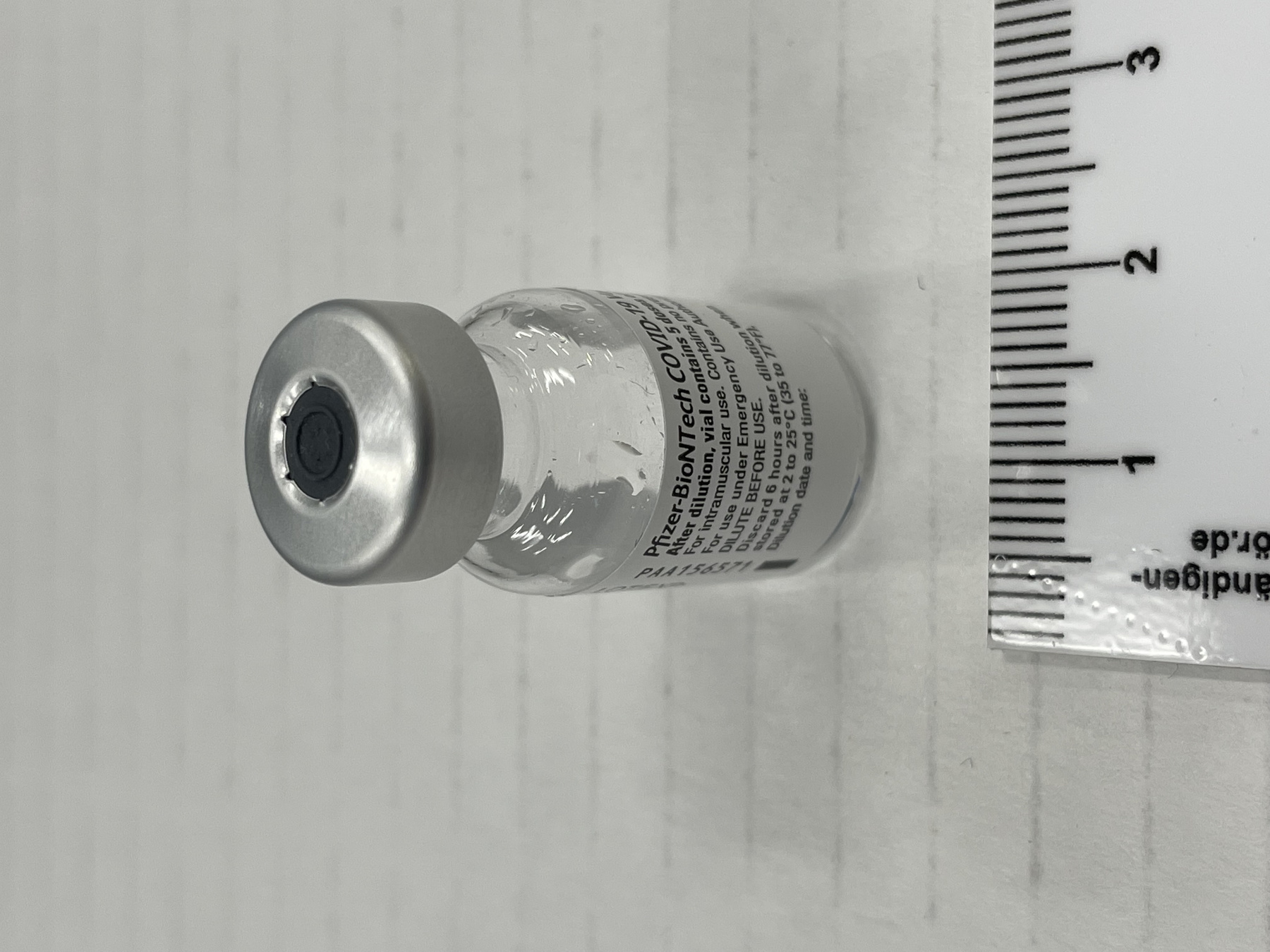

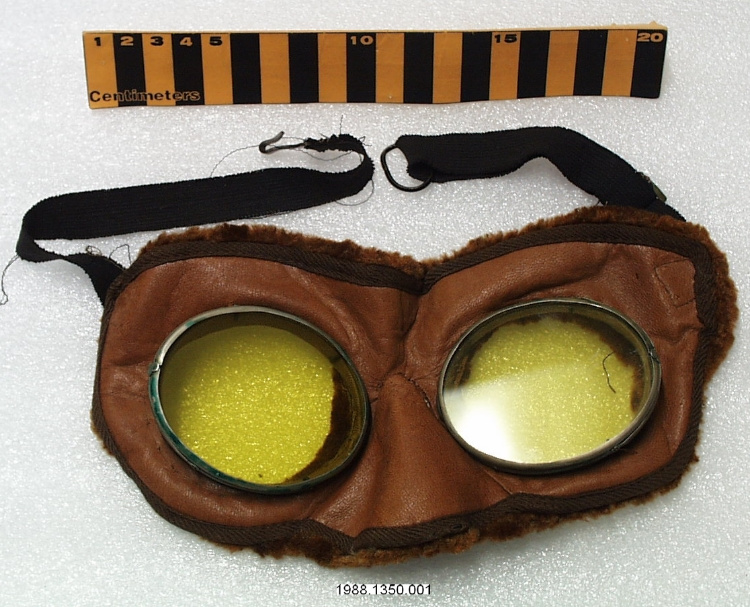

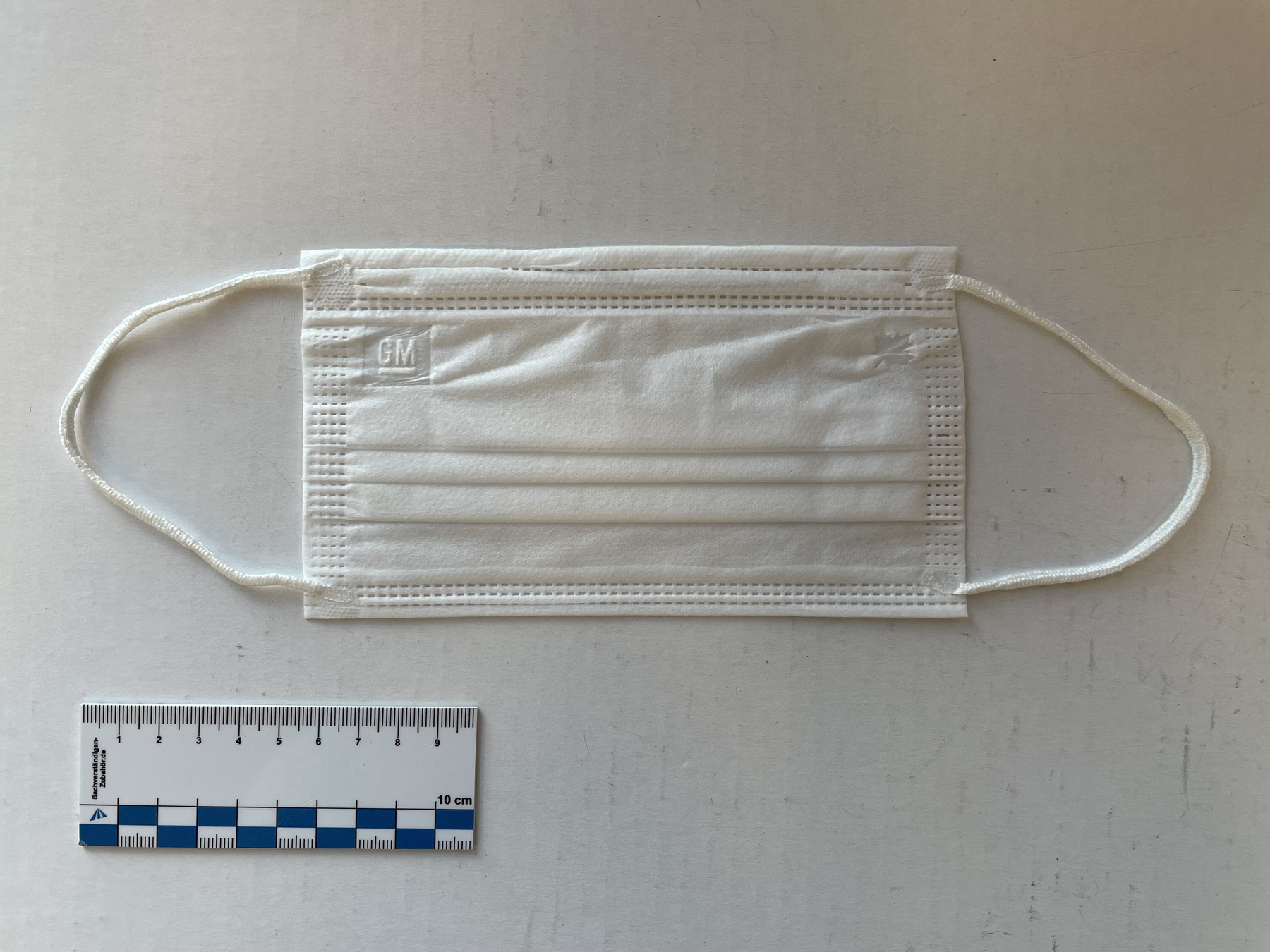

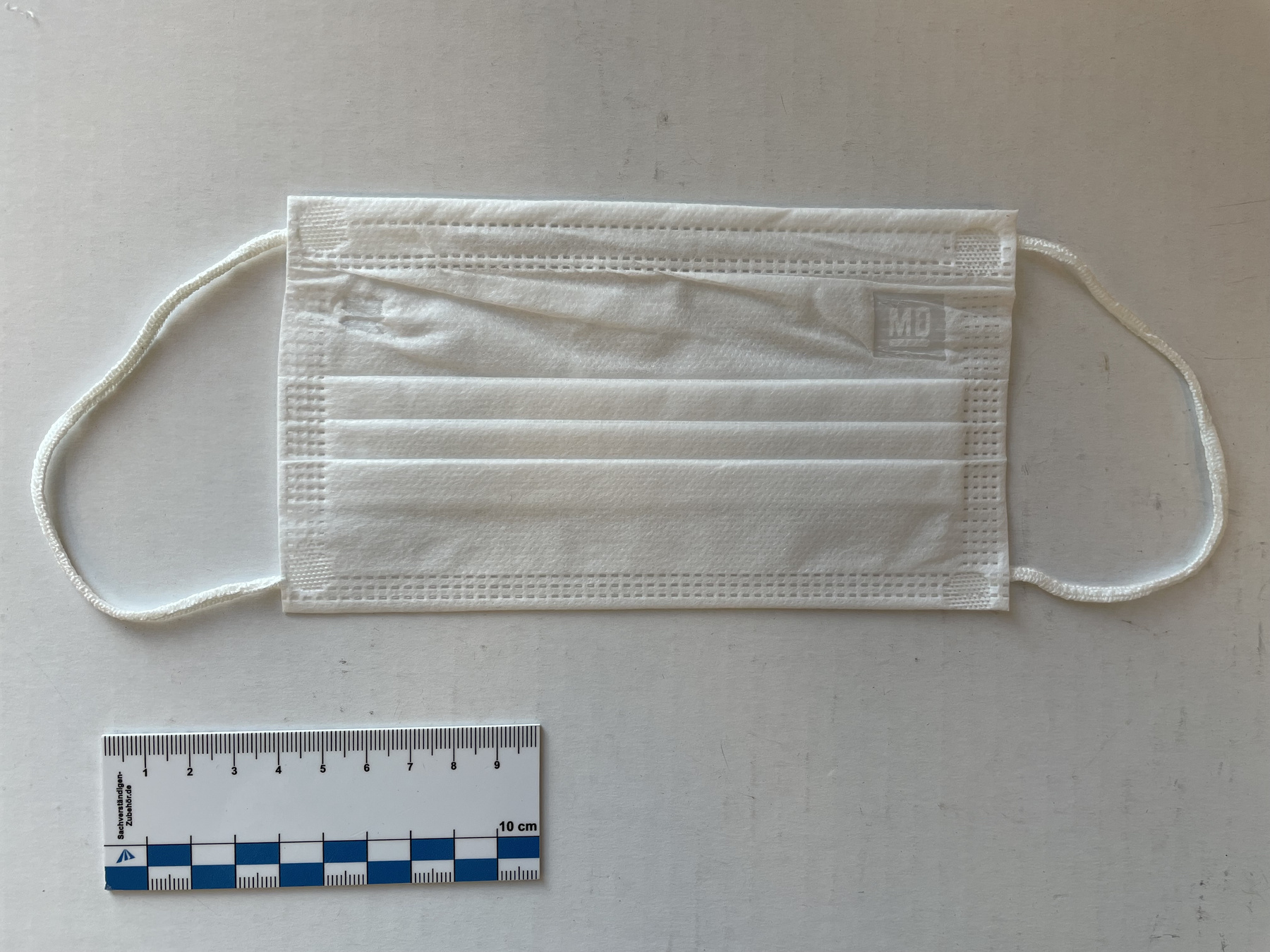

Masque chirurgical

Utiliser cette image

Puis-je réutiliser cette image sans autorisation? Oui

Les images sur le portail de la collection d’Ingenium ont la licence Creative Commons suivante :

Copyright Ingenium / CC BY-NC-ND (Attribution-NonCommercial 4.0 International (CC BY-NC 4.0)

ATTRIBUER CETTE IMAGE

Ingenium,

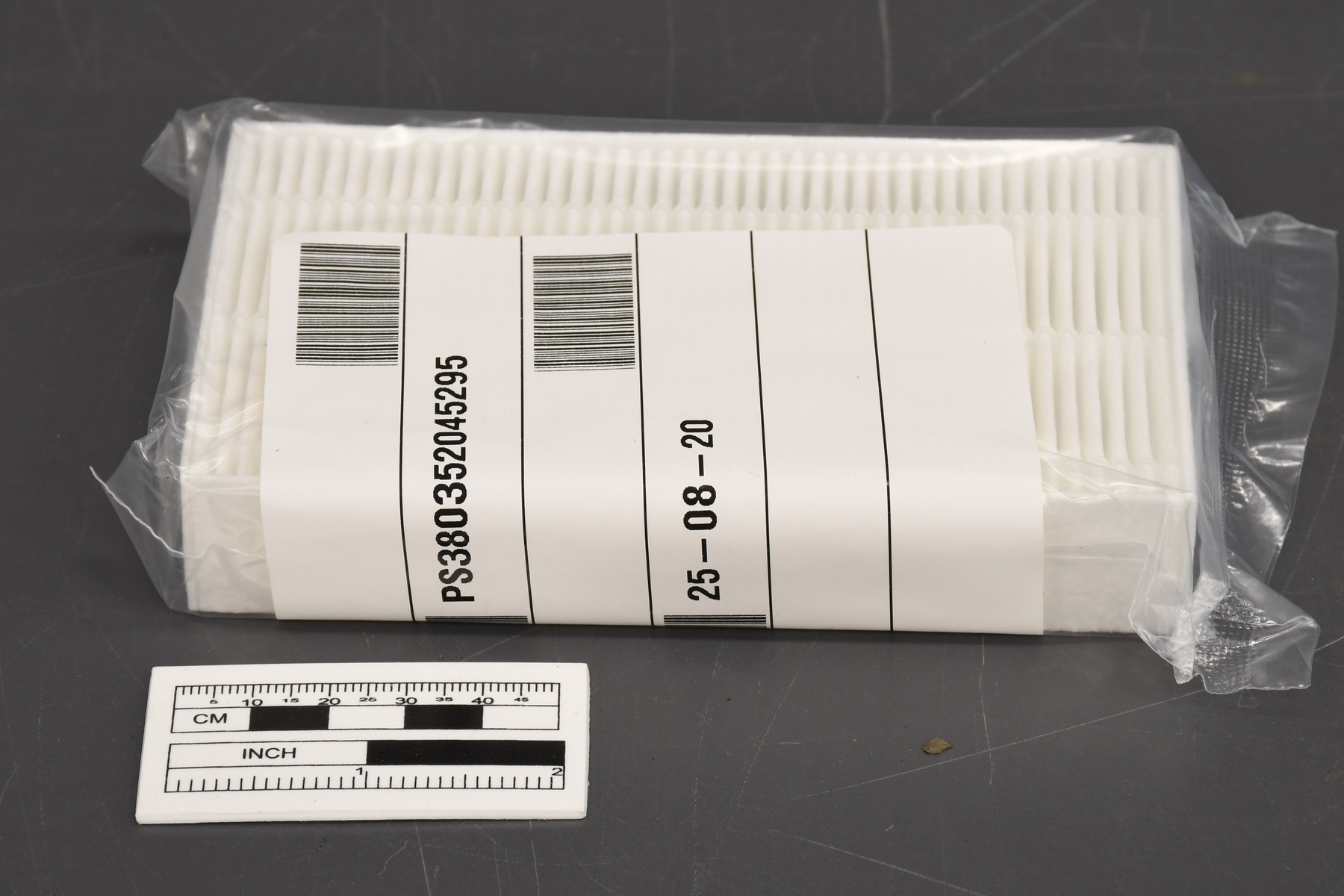

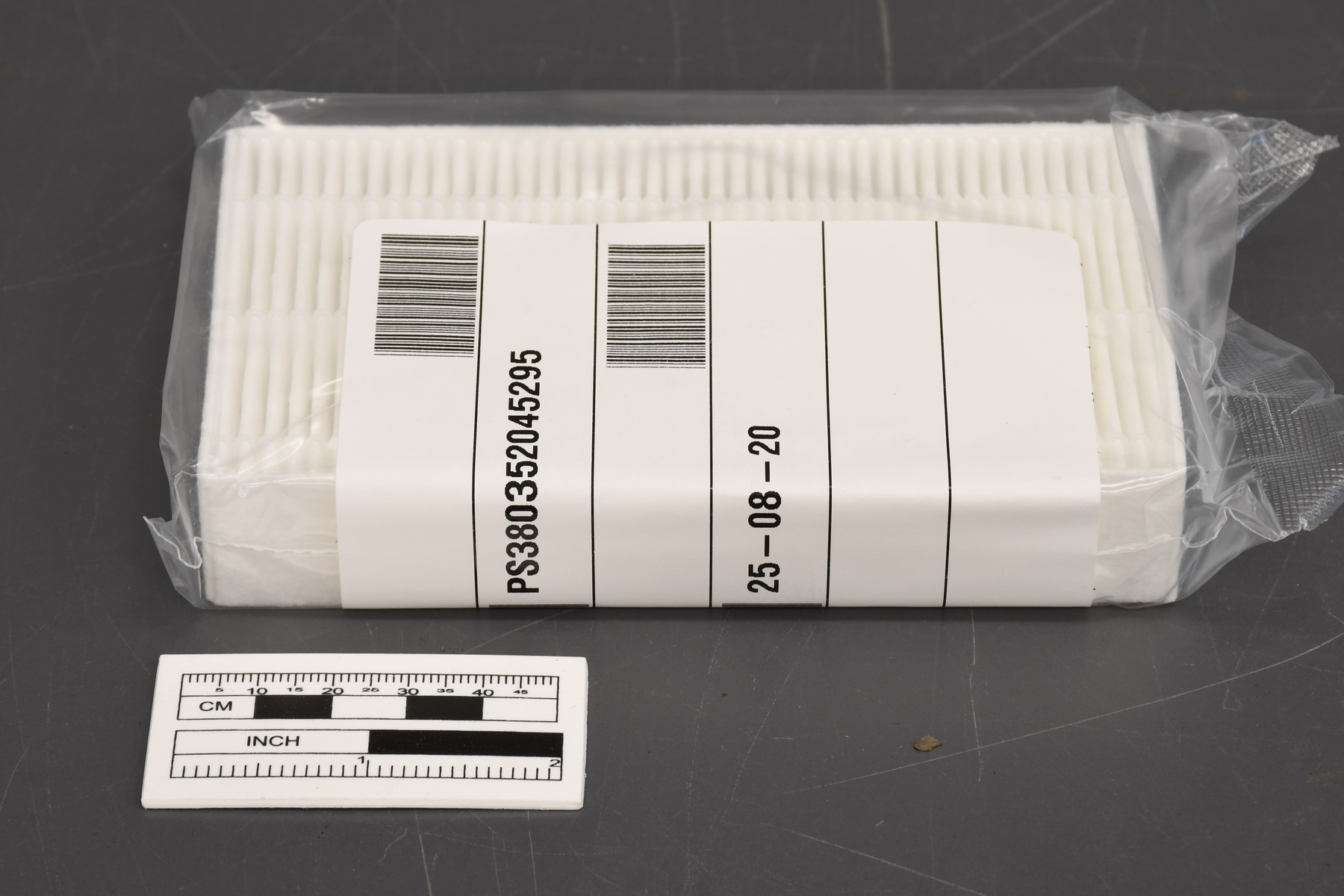

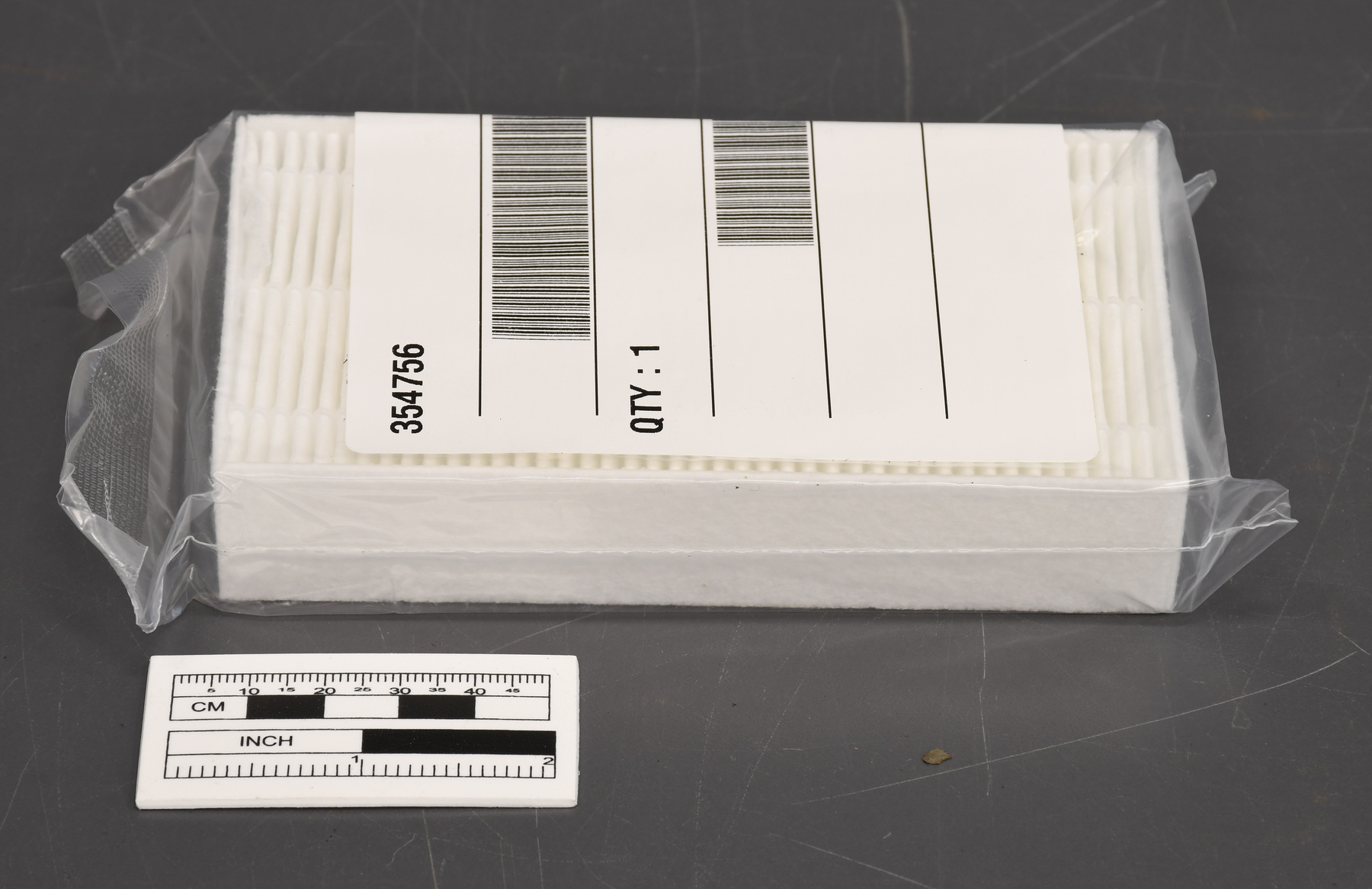

2021.0001.001

Permalien:

Ingenium diffuse cette image sous le cadre de licence Creative Commons et encourage son téléchargement et sa réutilisation à des fins non commerciales. Veuillez mentionner Ingenium et citer le numéro de l’artefact.

TÉLÉCHARGER L’IMAGEACHETER CETTE IMAGE

Cette image peut être utilisée gratuitement pour des fins non commerciales.

Pour un usage commercial, veuillez consulter nos frais de reproduction et communiquer avec nous pour acheter l’image.

- TYPE D’OBJET

- N95

- DATE

- 2021

- NUMÉRO DE L’ARTEFACT

- 2021.0001.001

- FABRICANT

- General Motors of Canada

- MODÈLE

- Inconnu

- EMPLACEMENT

- Oshawa, Ontario, Canada

Plus d’information

Renseignements généraux

- Nº de série

- 10000000

- Nº de partie

- 1

- Nombre total de parties

- 1

- Ou

- S/O

- Brevets

- S/O

- Description générale

- Synthetic and metal

Dimensions

Remarque : Cette information reflète la taille générale pour l’entreposage et ne représente pas nécessairement les véritables dimensions de l’objet.

- Longueur

- 9,6 cm

- Largeur

- 28,0 cm

- Hauteur

- S/O

- Épaisseur

- S/O

- Poids

- S/O

- Diamètre

- S/O

- Volume

- S/O

Lexique

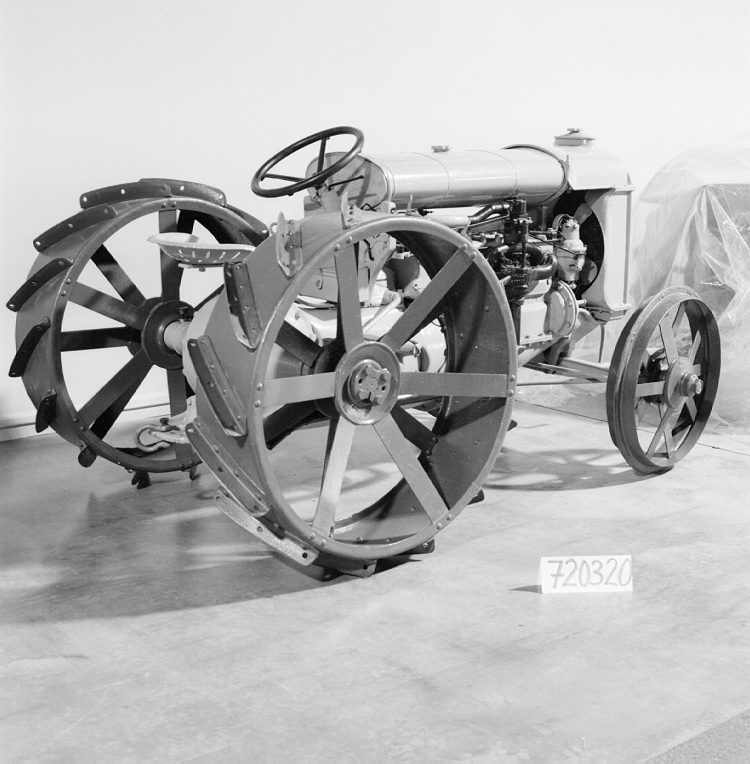

- Groupe

- Transports terrestres motorisés

- Catégorie

- Divers

- Sous-catégorie

- S/O

Fabricant

- Ou

- General Motors

- Pays

- Canada

- État/province

- Ontario

- Ville

- Oshawa

Contexte

- Pays

- Canada

- État/province

- Ontario

- Période

- New, never used

- Canada

-

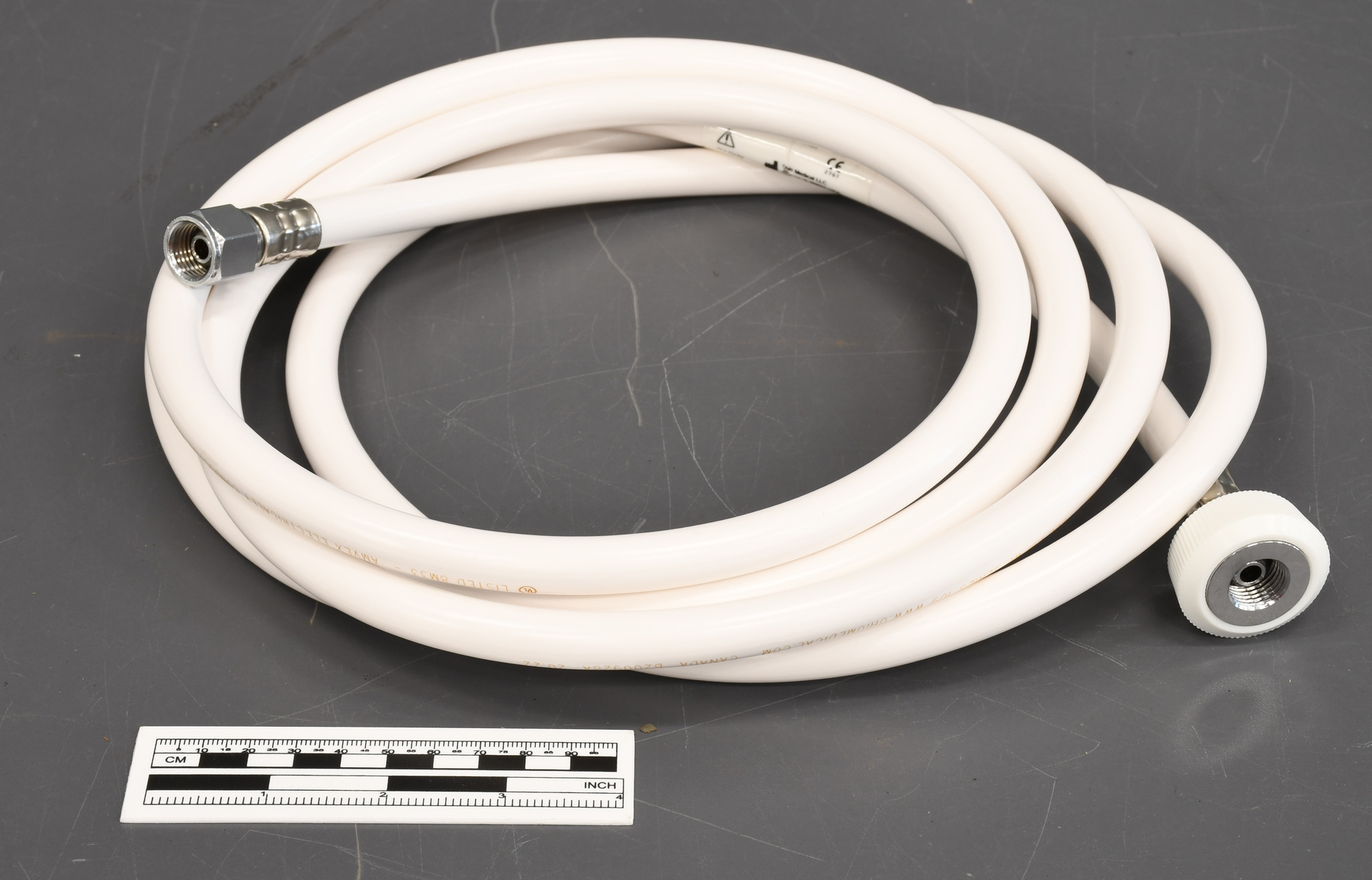

As per Acquisition proposal (see proposal for full transcipt, images, footnotes and references) "The first known case of COVID-19 in Canada dates to 23 January 2020. Within months, the country faced a critical N95 mask shortage; a central piece of PPE worn by health care professionals, many frontline workers, and, increasingly during this early period of the pandemic, Canadians looking to protect themselves and stop the spread of COVID-19. In response to this urgent need, on 24 April 2020, the Federal Minister of Innovation, Science and Industry announced that the government had signed a letter of intent with General Motors (GM) Canada which would see the manufacturer produce 10 million medical grade facemasks by the spring of 2021. GM Canada moved very quickly to ensure that the necessary pieces and spaces were in place so that they could begin production as soon as possible. The company successfully applied for a Medical Device Establishment License, which granted GM Canada permission to distribute medical devices in Canada. On the 29th of April, equipment for the mask making line arrived in Oshawa. GM Canada management, in consultation with GM colleagues in Warren, Michigan who had undertaken a very similar PPE making initiative a few weeks prior, selected a portion of the 5.1 million square meter plant that they then converted into an appropriate and functional space for production of N95 masks. During this time, staff at GM Canada and Oshawa Operations were also sourcing materials, producing enhanced safety protocols, installing equipment, and working with Unifor to recall and train 60 workers who were laid off in the fall of 2019 when the facility shuttered its assembly line operations. In the interviews I’ve completed with GM hourly and salaried staff, the fact that all this took place in just over three weeks time has been repeatedly stressed as significant and a source of pride for salaried and hourly employees. The Government of Canada issued a formal contract on 26 May 2020 for GM Canada to immediately begin manufacturing face masks at-cost at its Oshawa Operation for the Public Health Agency of Canada. One month later, GM Canada’s first shipment of masks, 436,000 in total, was shipped to the GOC. A few weeks later, on 10 July 2020, GM Canada produced its one millionth mask. The auto maker has celebrated each millionth milestone by inviting guests, such as municipal government leaders, local GM dealers, charitable organizations and business partners, to tour the Canadian Mask Making (CMM) room and sign a CMM banner. On 8 April 2021, GM Canada fulfilled its commitment to the Government of Canada to produce 10 million face masks at-cost. After fulfilling its obligation to the Canadian Government, GM Canada also produced nearly 500,000 additional masks that were distributed to its nearly 450 dealerships. In turn, dealers donated the masks to local charities of their choice across Canada. GM and GM Canada’s mask making operations are part of a larger discourse surrounding how industries are responding to the pandemic. In some cases, industries with the capabilities to do so are ‘pivoting’ their production and work products in order to address new needs and shortages caused by COVID-19, or rather the ensuing pandemic realities. In other cases, no such retooling was possible and industries have shuttered or been forced to permanently close their doors and cease operations. A major effort of the Curating Under Quarantine initiative has been to explore, document, and examine the myriad of ways that Canada’s science and technology industries (broadly defined) are responding to COVID-19. For now, these oral histories and accompanying photo documentation can be found here: S:\Curatorial Services\Curating Under Quarantine\Documenting Industry Reactions to COVID 19" - Fonction

-

To cover nose and mouth and prevent wearer from transmitting airborne pathogens. - Technique

-

As per Acquisition proposal (see proposal for full transcipt, footnotes and references) "In response to the COVID-19 pandemic, General Motors began producing face masks in Warren, Michigan and in China in the spring of 2020; the latter was through a joint venture with SAIC-GM-Wuling. The auto maker relied on existing supply chains and networks in order to make this shift in production. For example, the company sourced material from suppliers JR Automation in Holland, Michigan and Esys Automation in Auburn Hills, Michigan who typically provide GM with automotive-manufacturing equipment. For GM’s face mask production, JR and Esys, subsidiary companies of Hitachi LTD, collaborated in order to build a mask line that automatically folds, welds, and cuts face masks. GM was also able to source mask material from companies that typically provide the manufacturer with sound-deadening insulation found in doors, headliners, and trunks. These existing supply chains were instrumental in GM’s ability to quickly begin producting masks and, in turn, allowed GM Canada to establish their on mask making operations in Oshawa, Ontario. - Notes sur la région

-

Inconnu

Détails

- Marques

- Embossed into fabric "GM" and the a maple leaf.

- Manque

- Appears complete

- Fini

- White synthetic fabric with two ear loops and a metal nose bridge wire.

- Décoration

- Maple leaf representing Canada.

FAIRE RÉFÉRENCE À CET OBJET

Si vous souhaitez publier de l’information sur cet objet de collection, veuillez indiquer ce qui suit :

General Motors of Canada, Masque chirurgical, 2021, Numéro de l'artefact 2021.0001, Ingenium - Musées des sciences et de l'innovation du Canada, http://collection.ingeniumcanada.org/fr/id/2021.0001.001/

RÉTROACTION

Envoyer une question ou un commentaire sur cet artefact.

Plus comme ceci