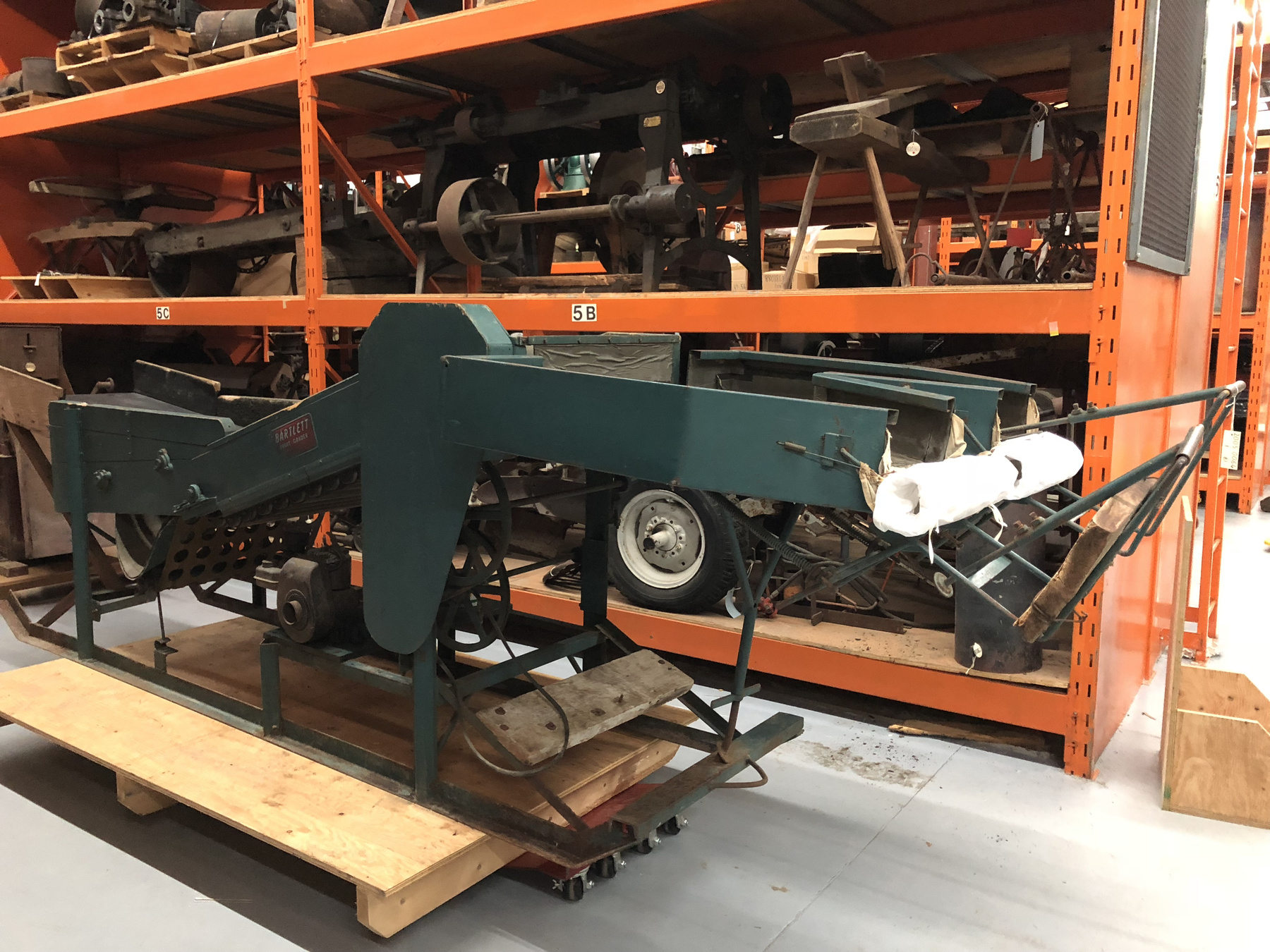

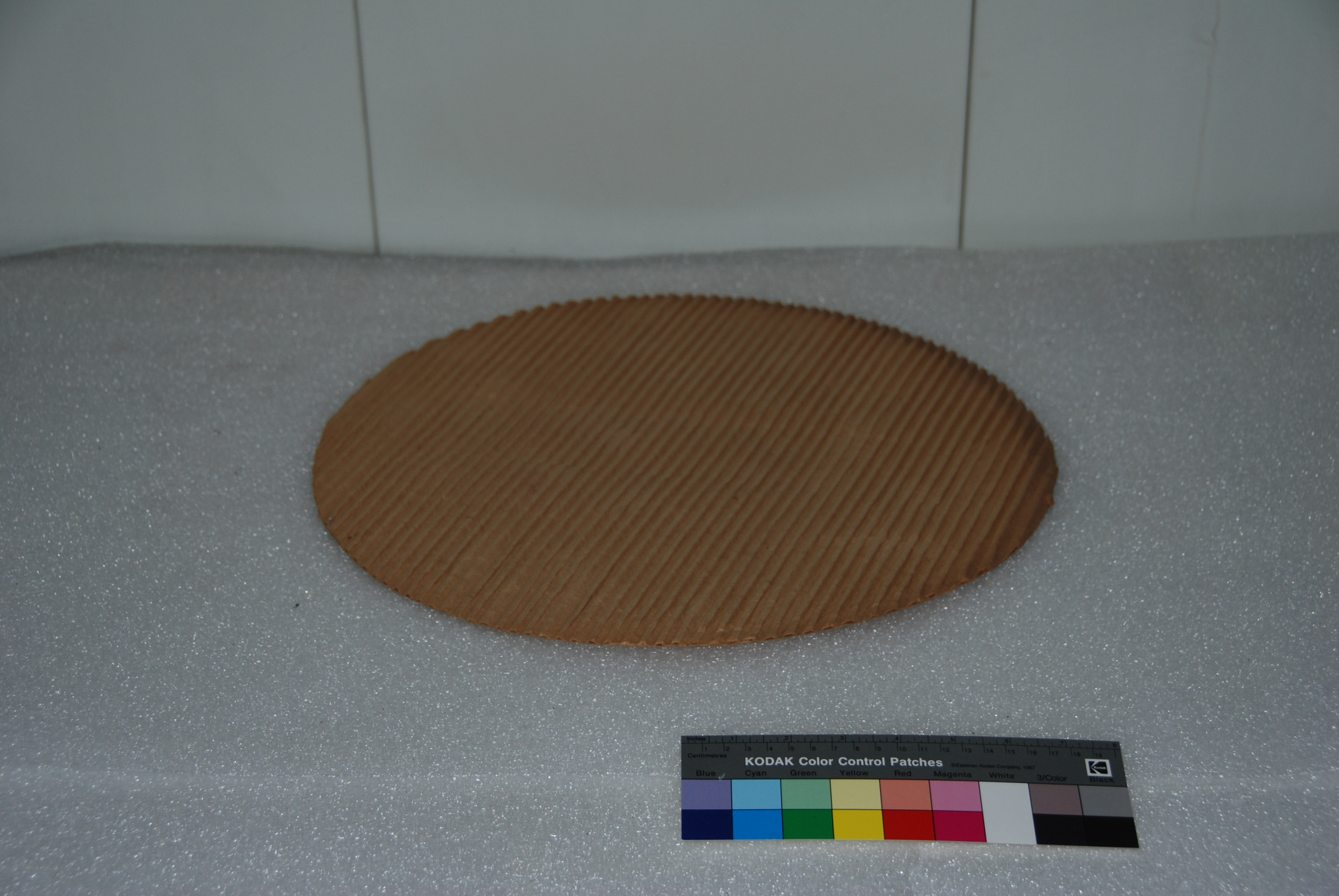

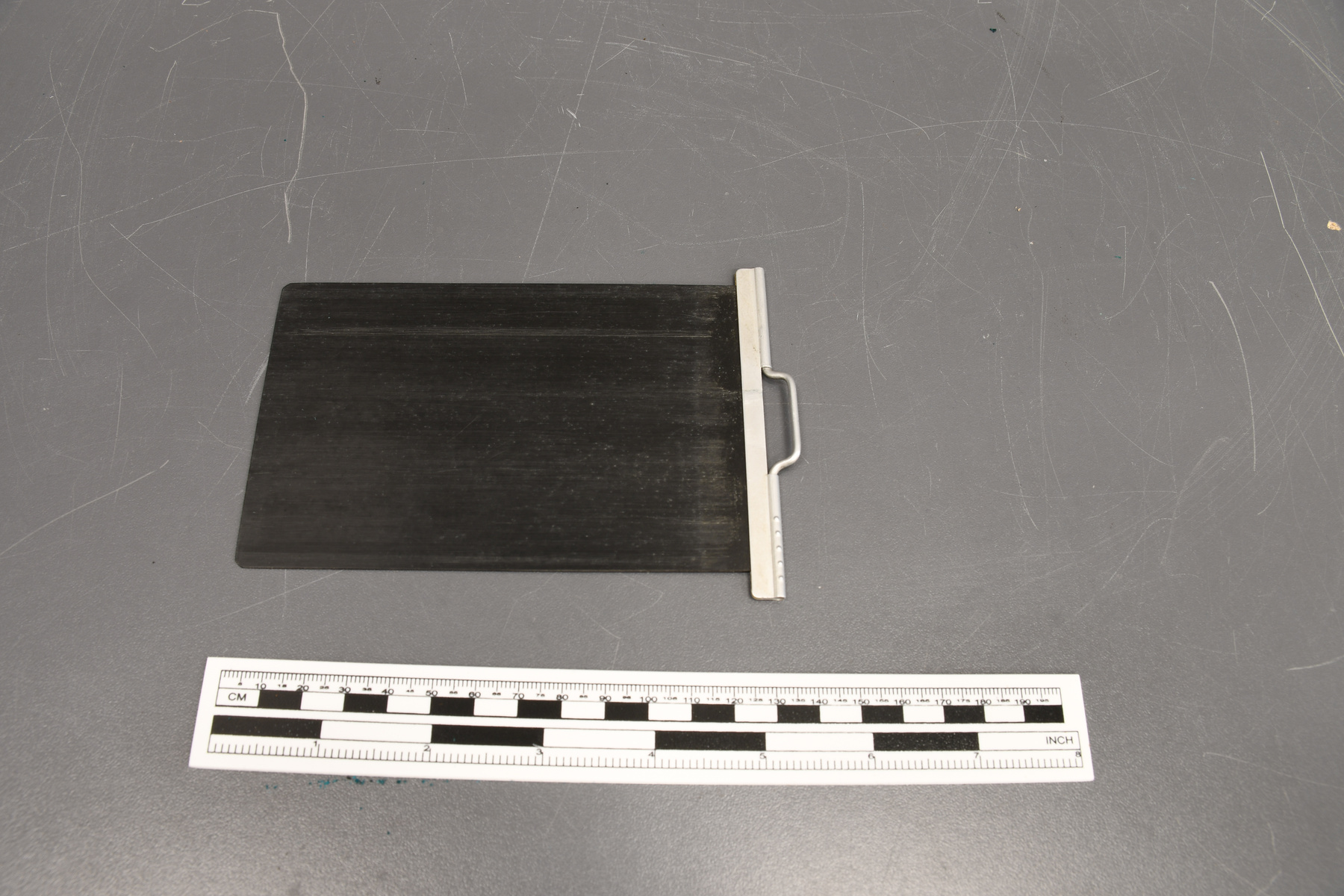

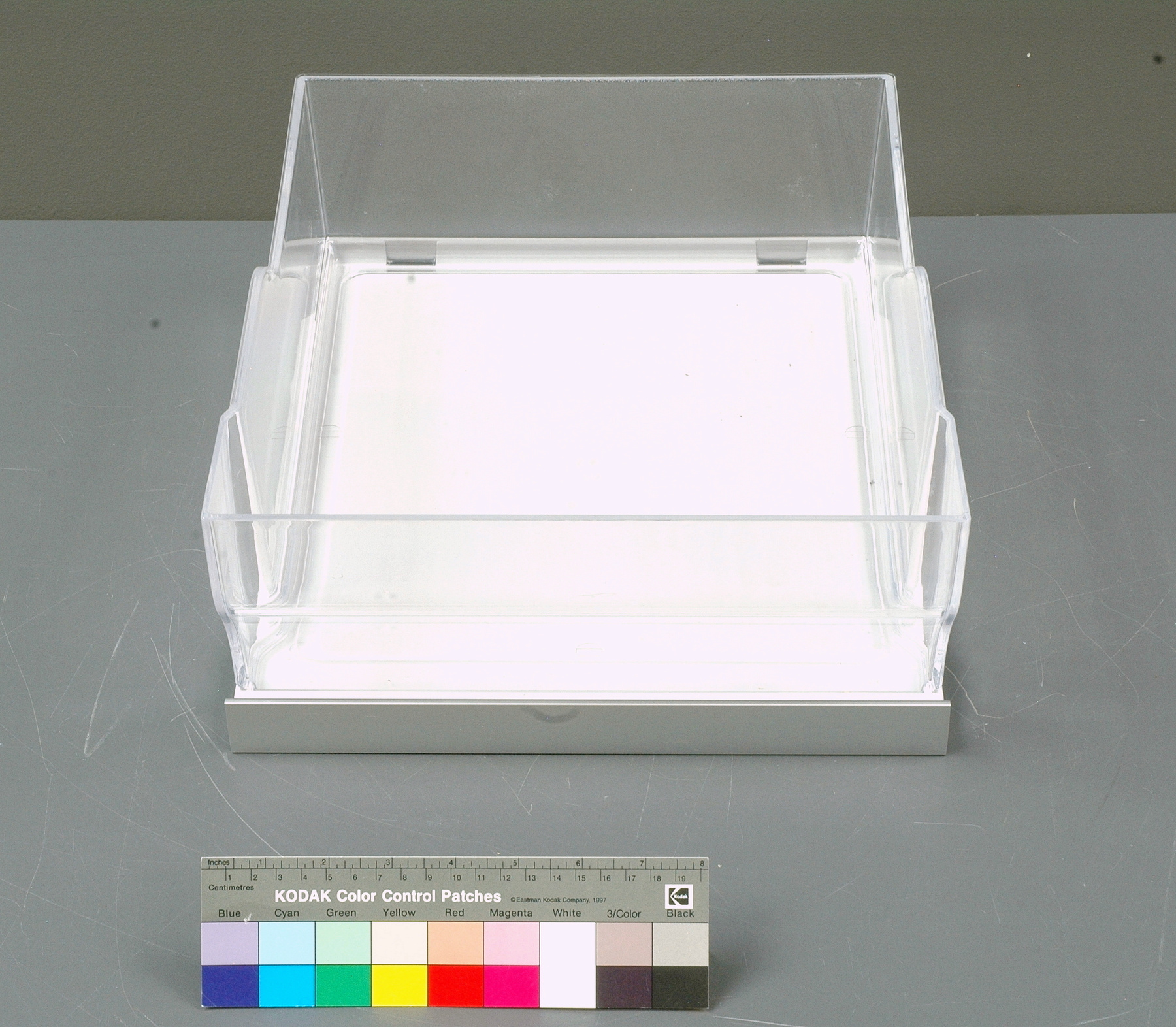

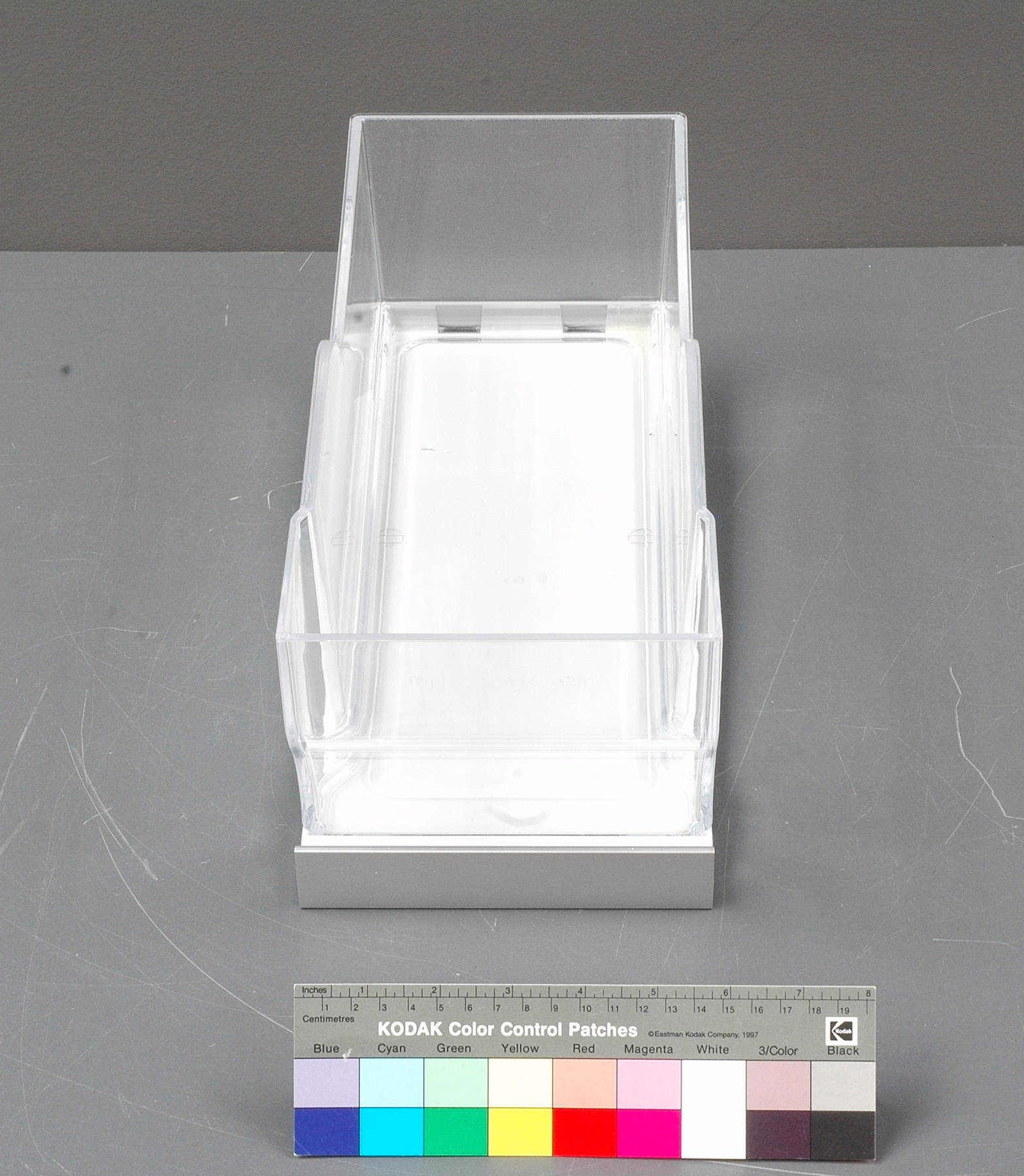

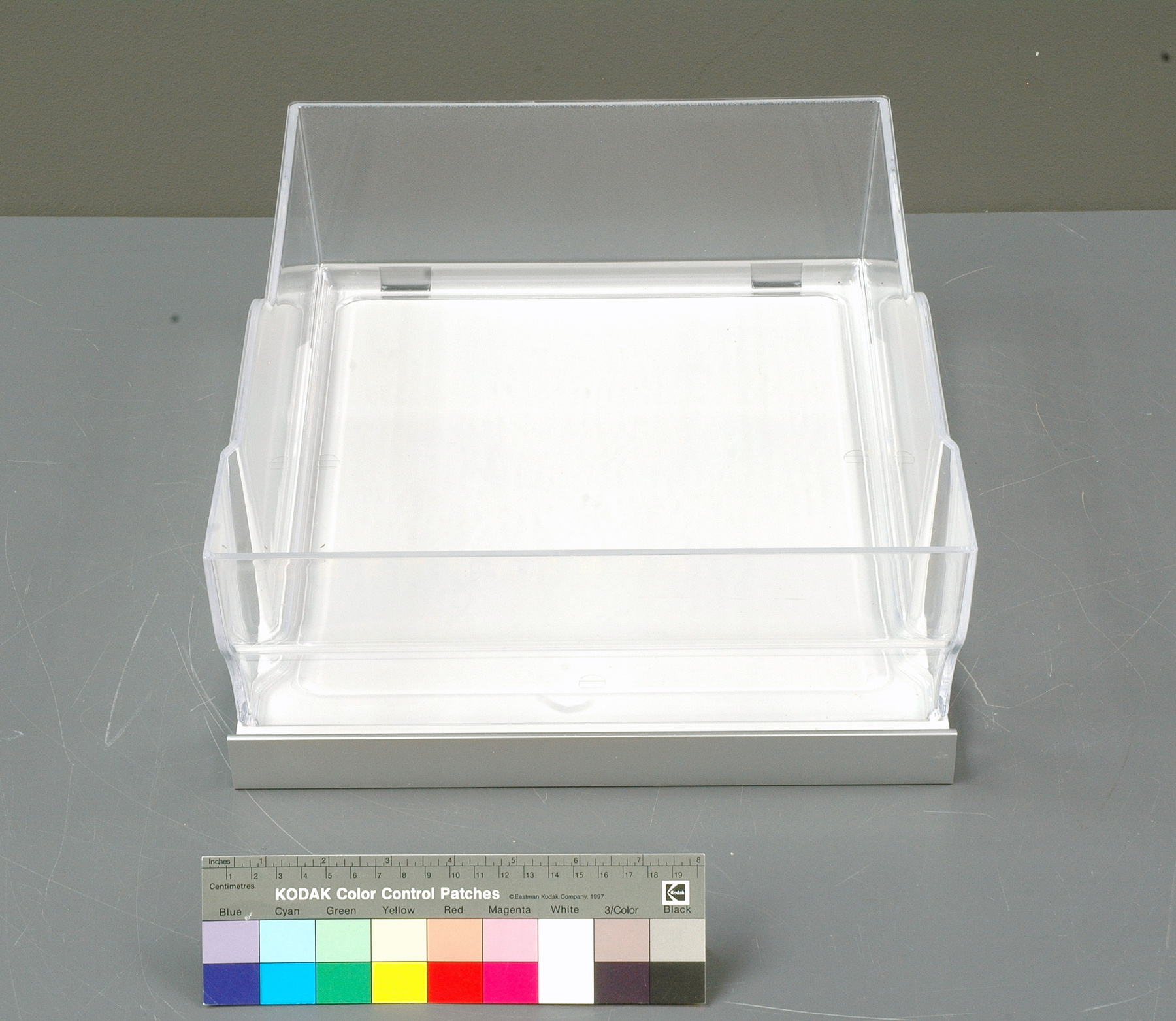

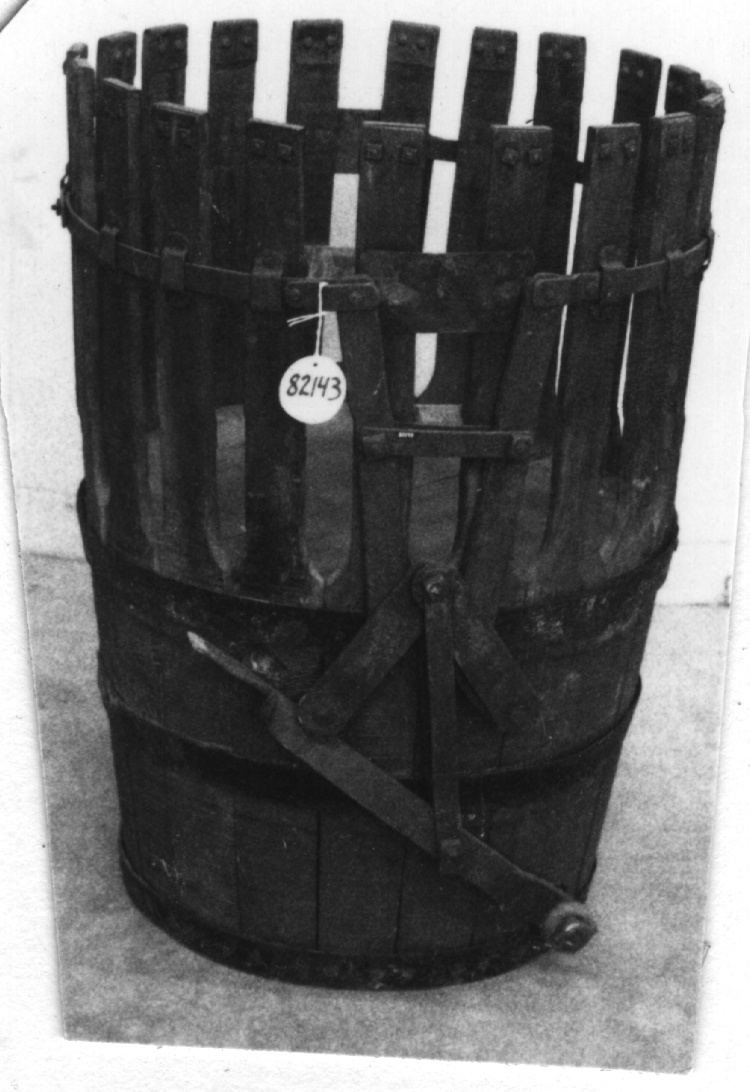

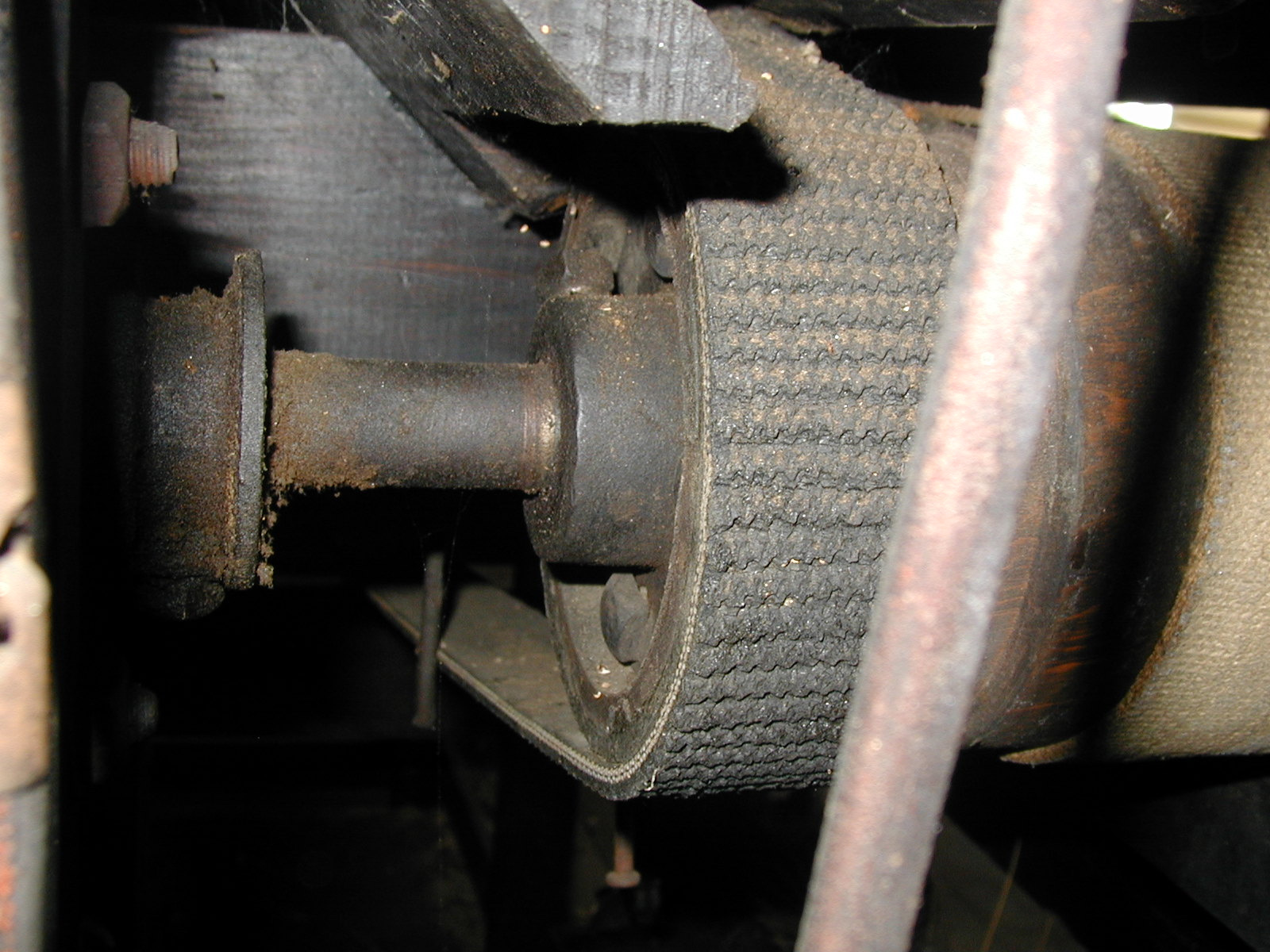

Grader & sizer, fruit & vegetable

Utiliser cette image

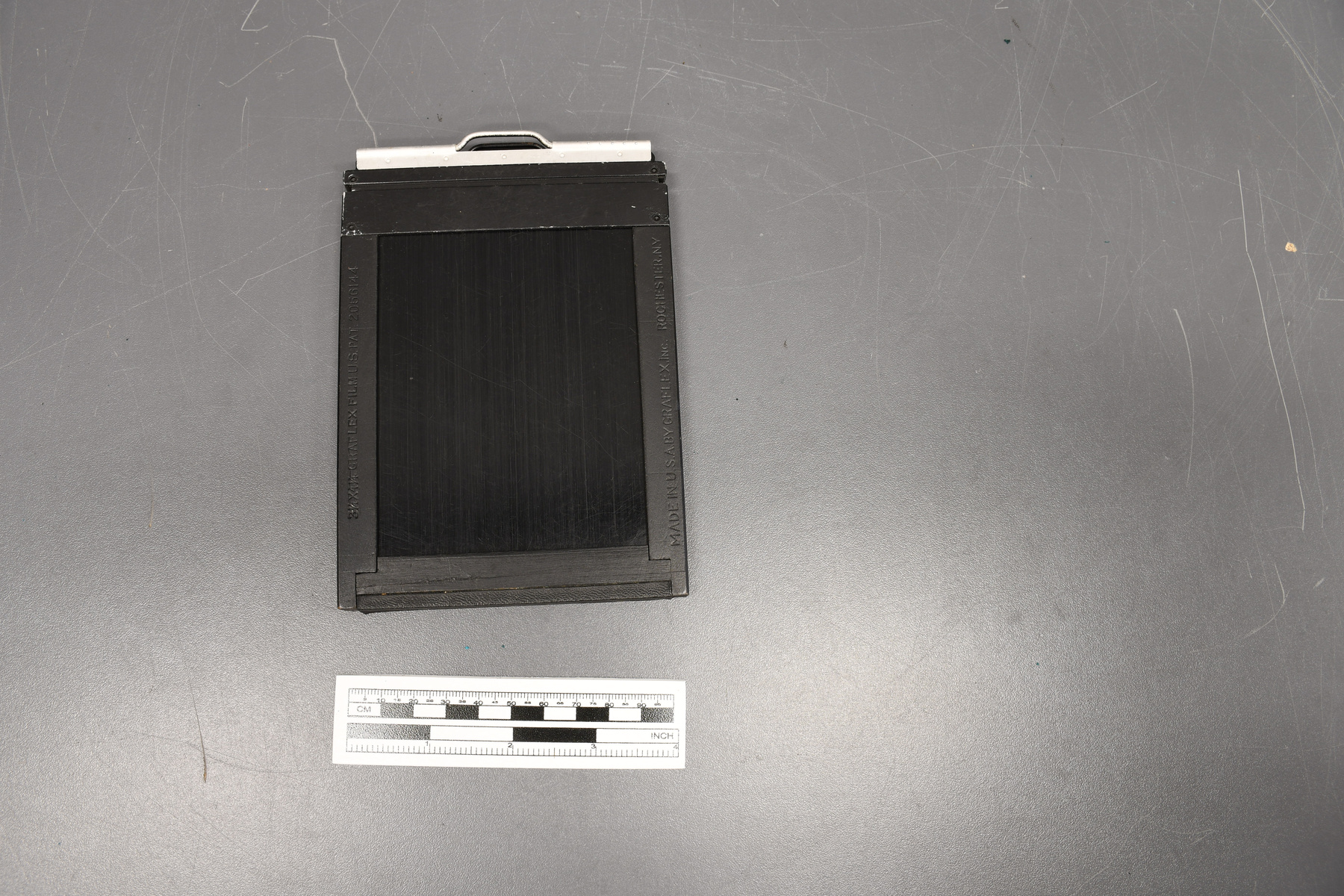

Puis-je réutiliser cette image sans autorisation? Oui

Les images sur le portail de la collection d’Ingenium ont la licence Creative Commons suivante :

Copyright Ingenium / CC BY-NC-ND (Attribution-NonCommercial 4.0 International (CC BY-NC 4.0)

ATTRIBUER CETTE IMAGE

Ingenium,

2010.0294.001

Permalien:

Ingenium diffuse cette image sous le cadre de licence Creative Commons et encourage son téléchargement et sa réutilisation à des fins non commerciales. Veuillez mentionner Ingenium et citer le numéro de l’artefact.

TÉLÉCHARGER L’IMAGEACHETER CETTE IMAGE

Cette image peut être utilisée gratuitement pour des fins non commerciales.

Pour un usage commercial, veuillez consulter nos frais de reproduction et communiquer avec nous pour acheter l’image.

- TYPE D’OBJET

- Electric

- DATE

- 1930

- NUMÉRO DE L’ARTEFACT

- 2010.0294.001

- FABRICANT

- Wayland Machinery Co. Inc.

- MODÈLE

- Inconnu

- EMPLACEMENT

- Covesville, Virginia, United States of America

Plus d’information

Renseignements généraux

- Nº de série

- 405

- Nº de partie

- 1

- Nombre total de parties

- 29

- Ou

- S/O

- Brevets

- S/O

- Description générale

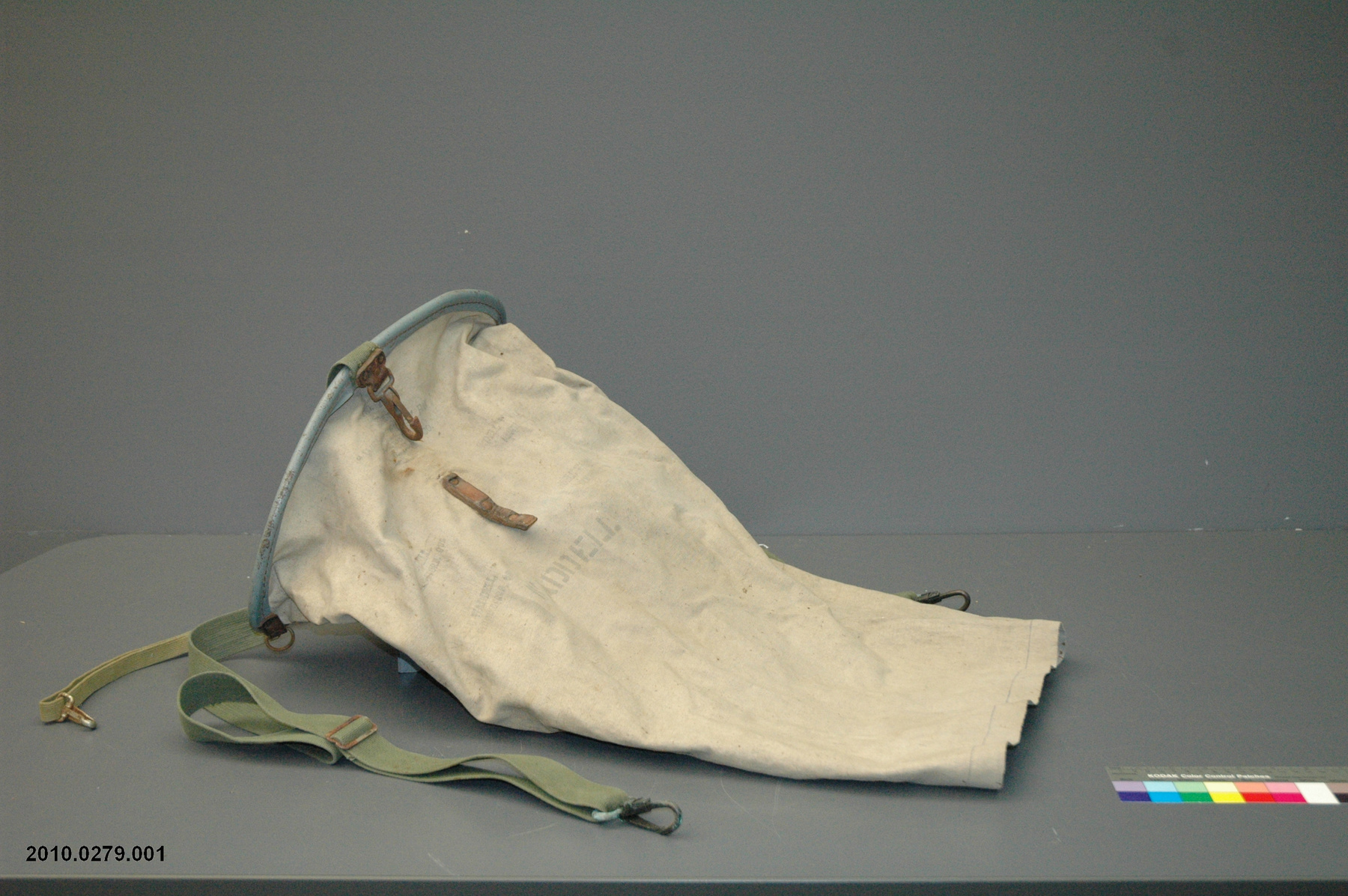

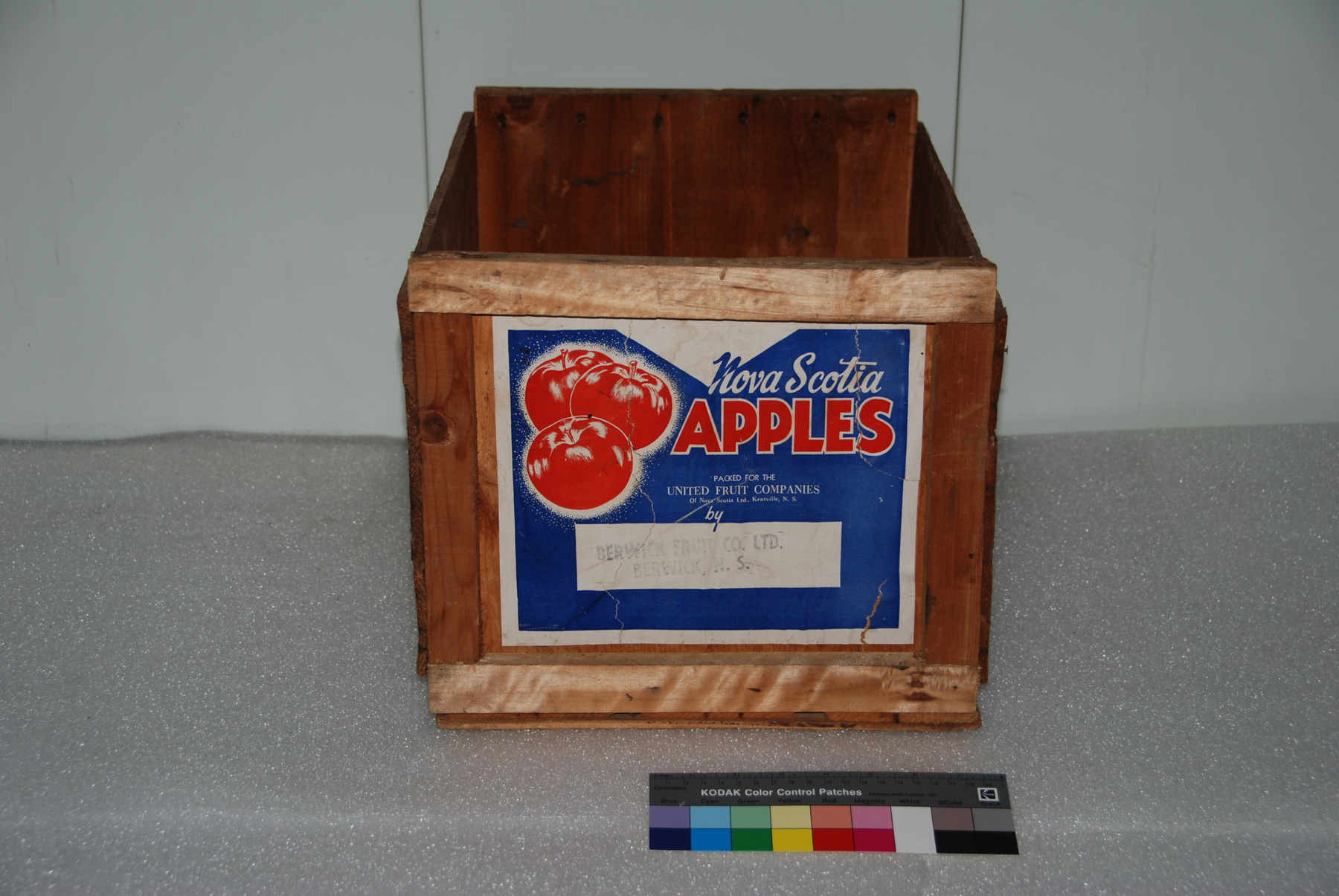

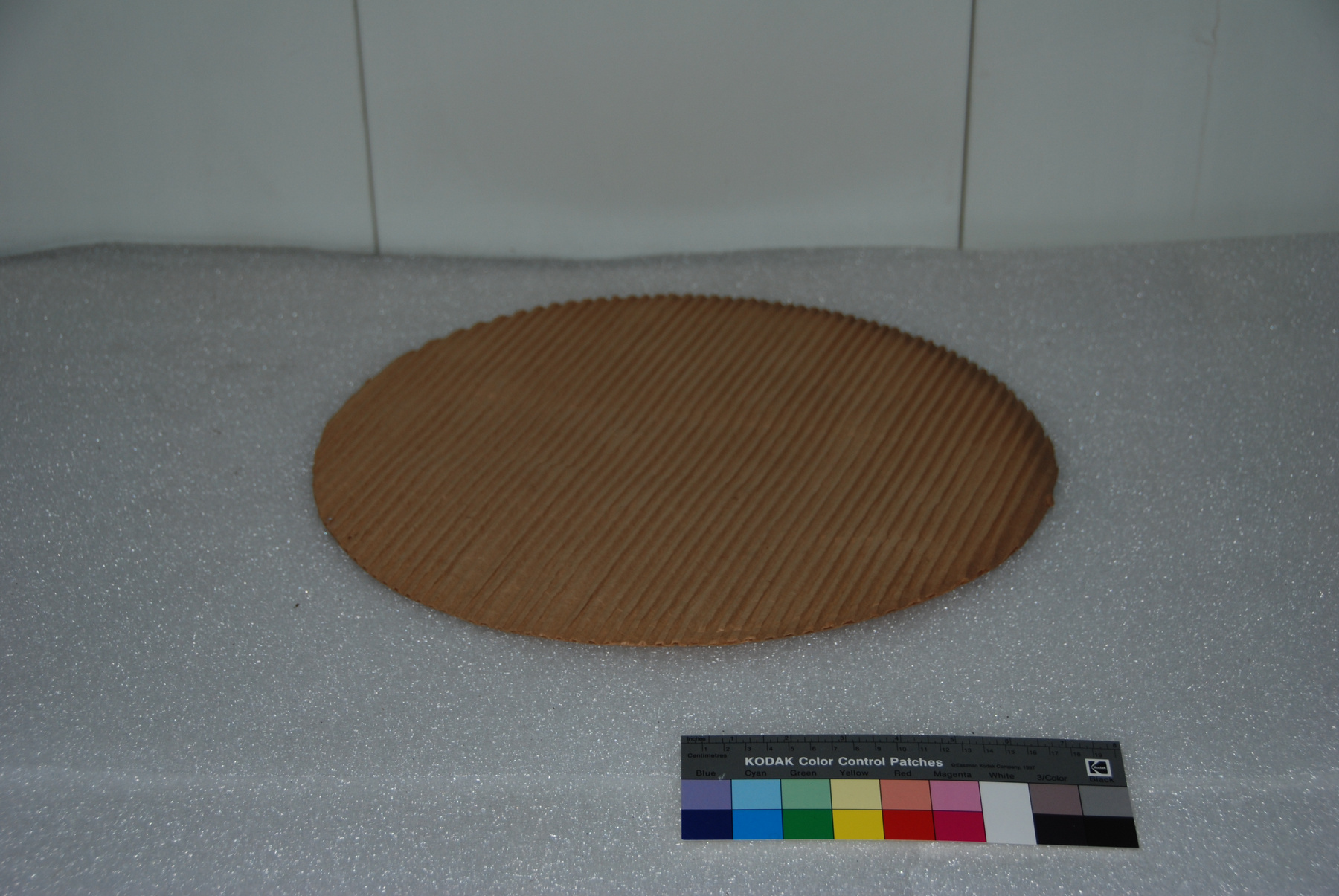

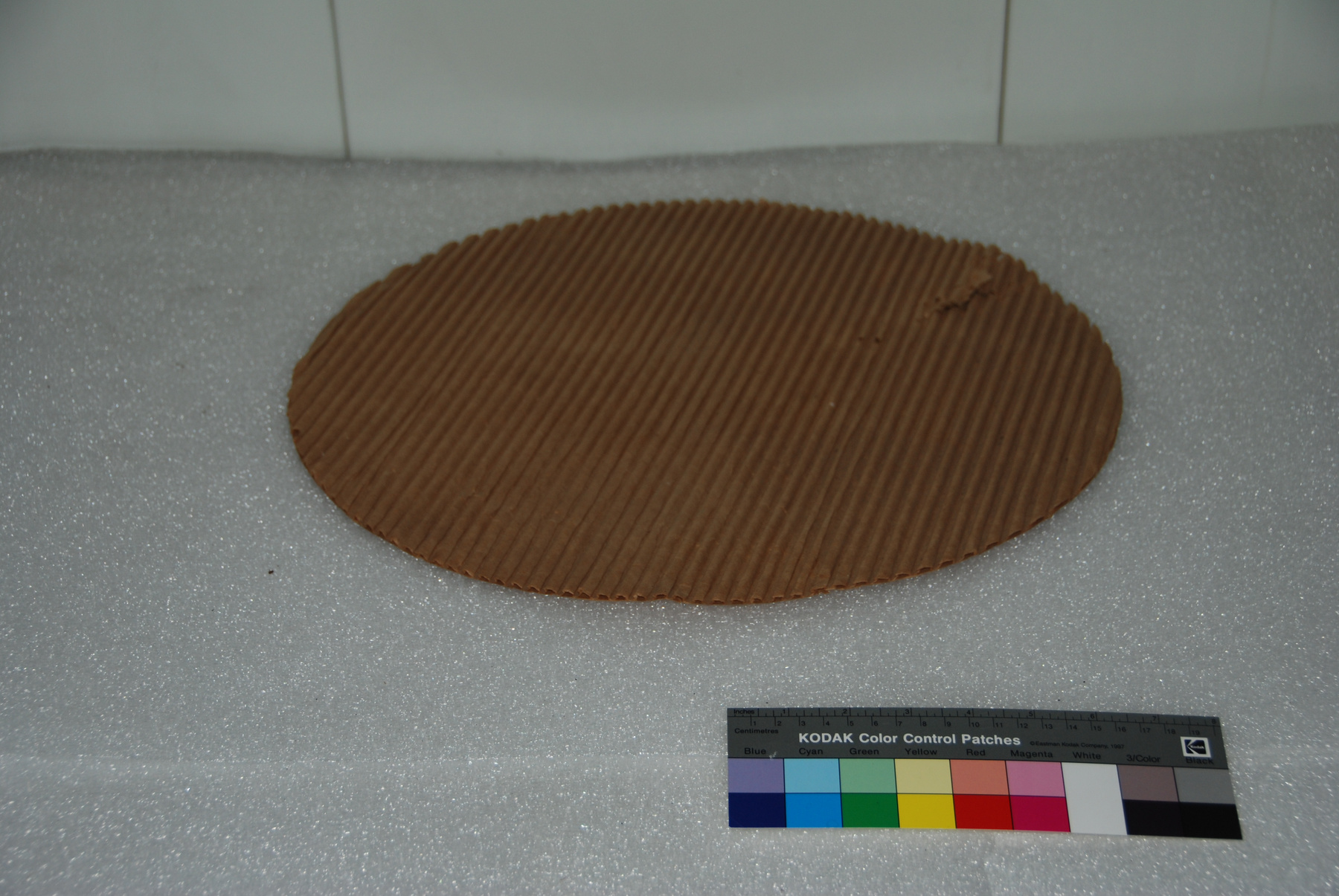

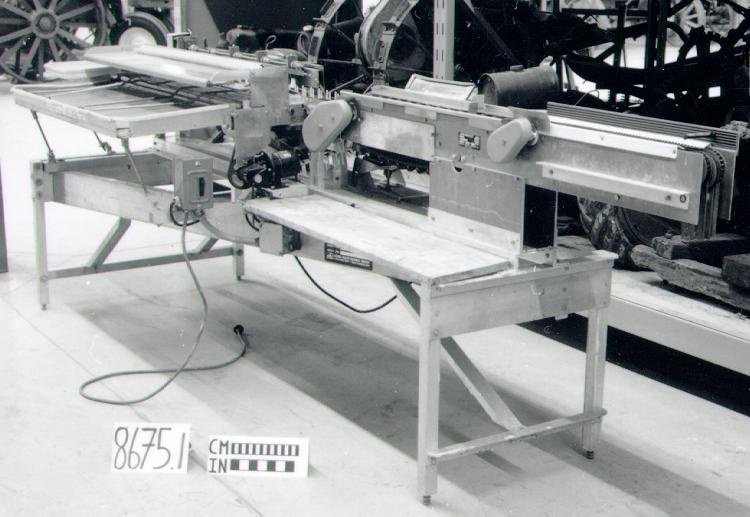

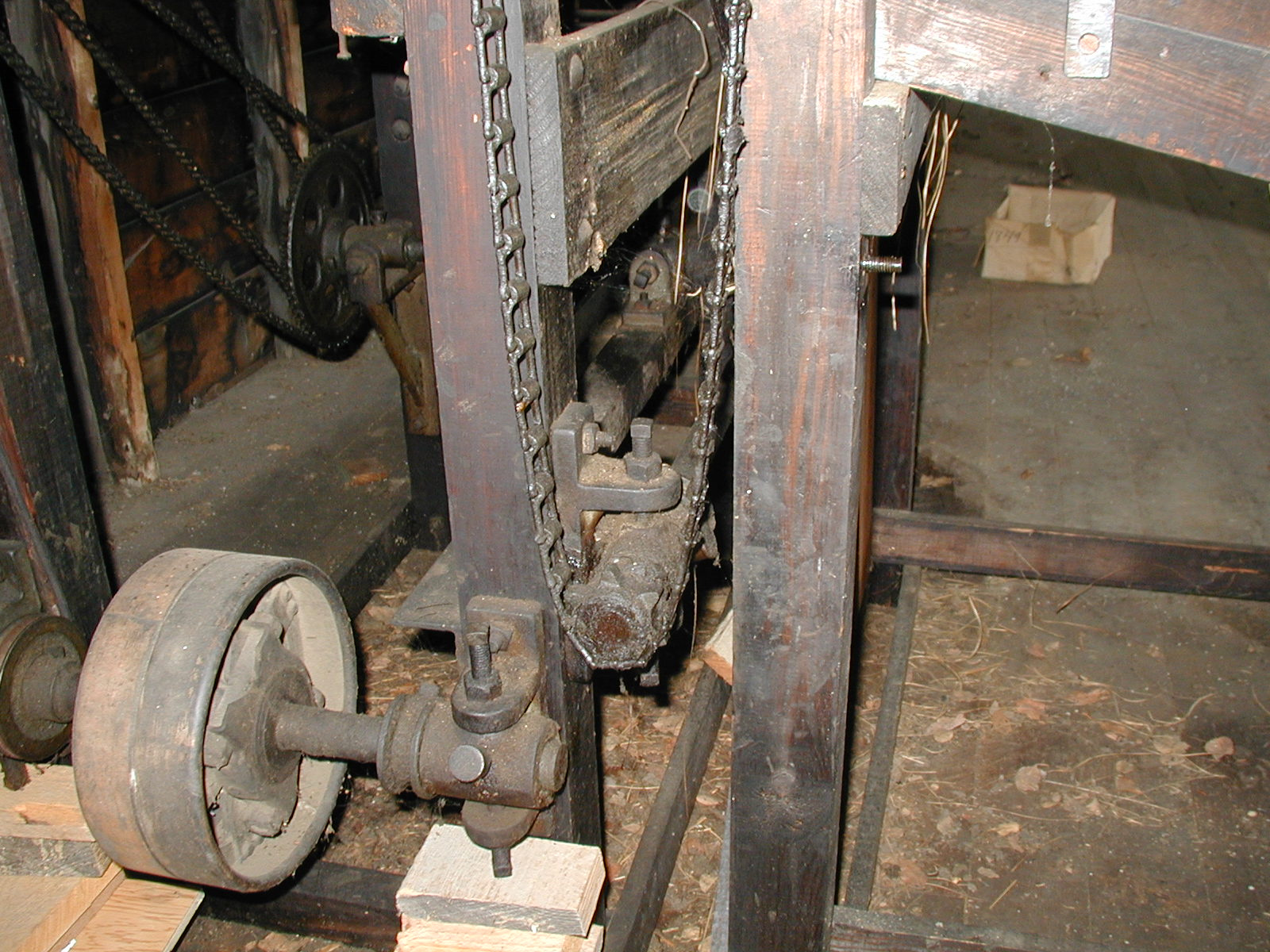

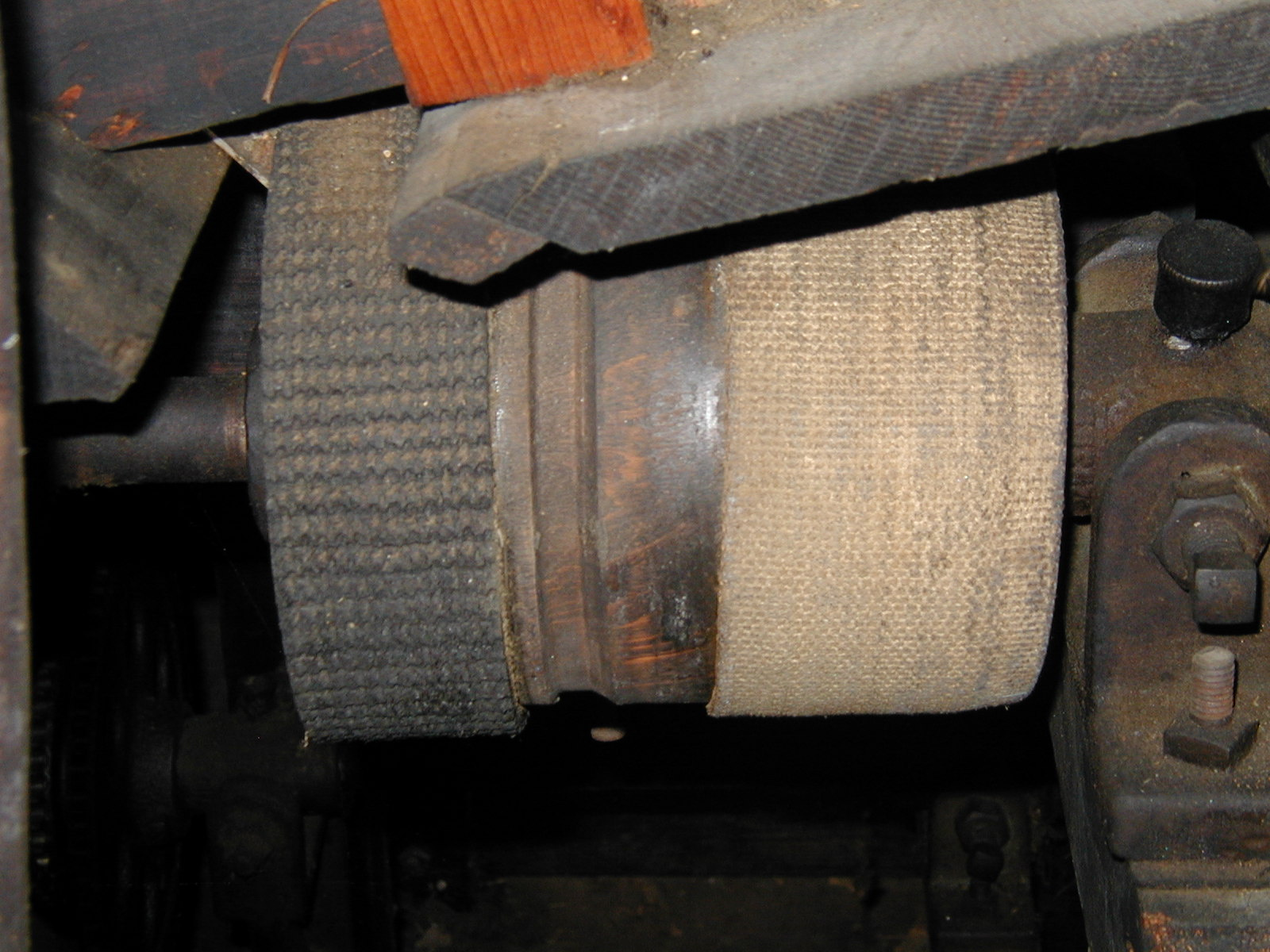

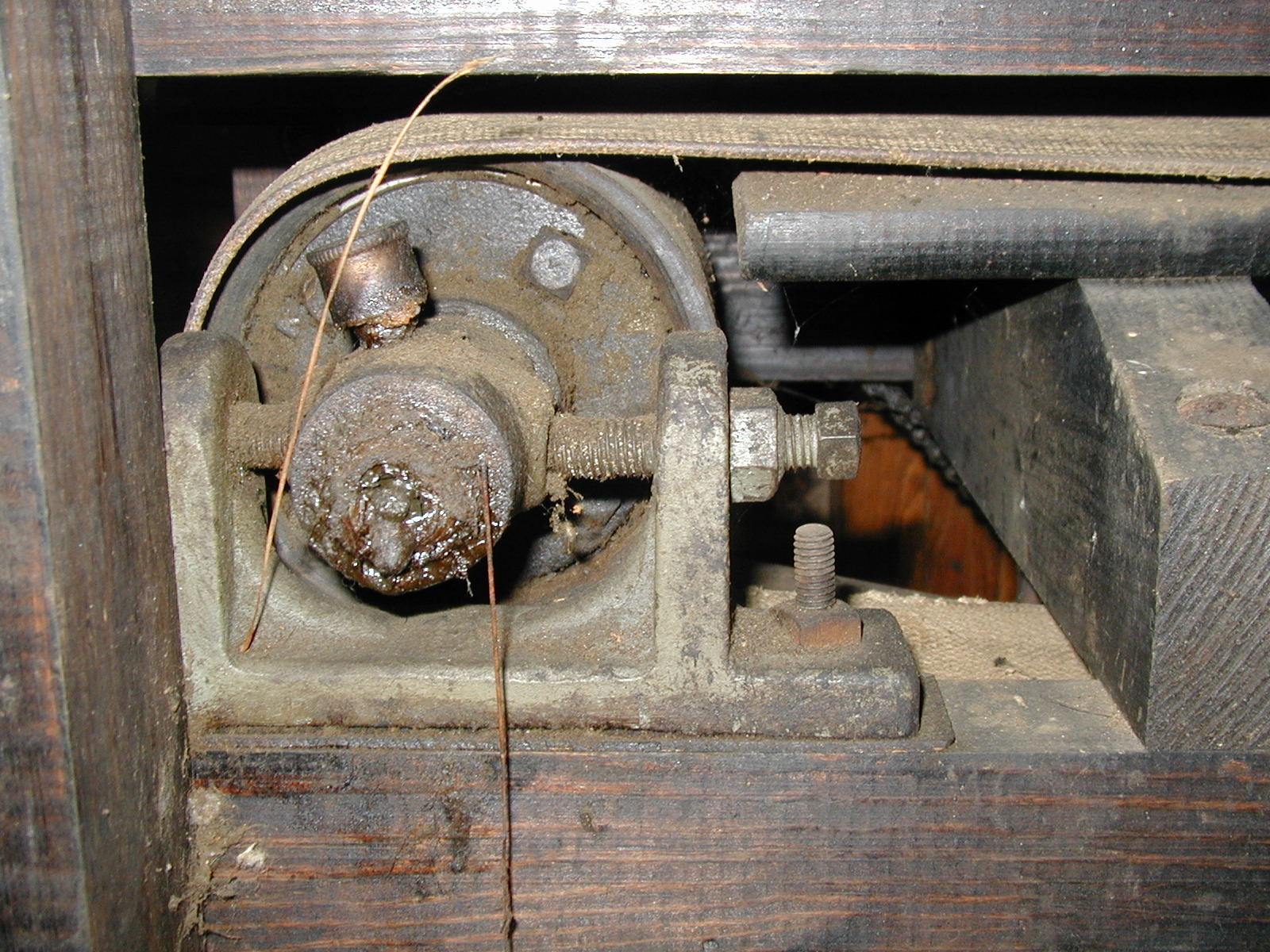

- Equipment generally composed of wood, metal, canvas and rubber.

Dimensions

Remarque : Cette information reflète la taille générale pour l’entreposage et ne représente pas nécessairement les véritables dimensions de l’objet.

- Longueur

- S/O

- Largeur

- S/O

- Hauteur

- S/O

- Épaisseur

- S/O

- Poids

- S/O

- Diamètre

- S/O

- Volume

- S/O

Lexique

- Groupe

- Agriculture

- Catégorie

- Traitement de récolte

- Sous-catégorie

- S/O

Fabricant

- Ou

- Wayland

- Pays

- United States of America

- État/province

- Virginia

- Ville

- Covesville

Contexte

- Pays

- Canada

- État/province

- Québec

- Période

- 1930's +

- Canada

-

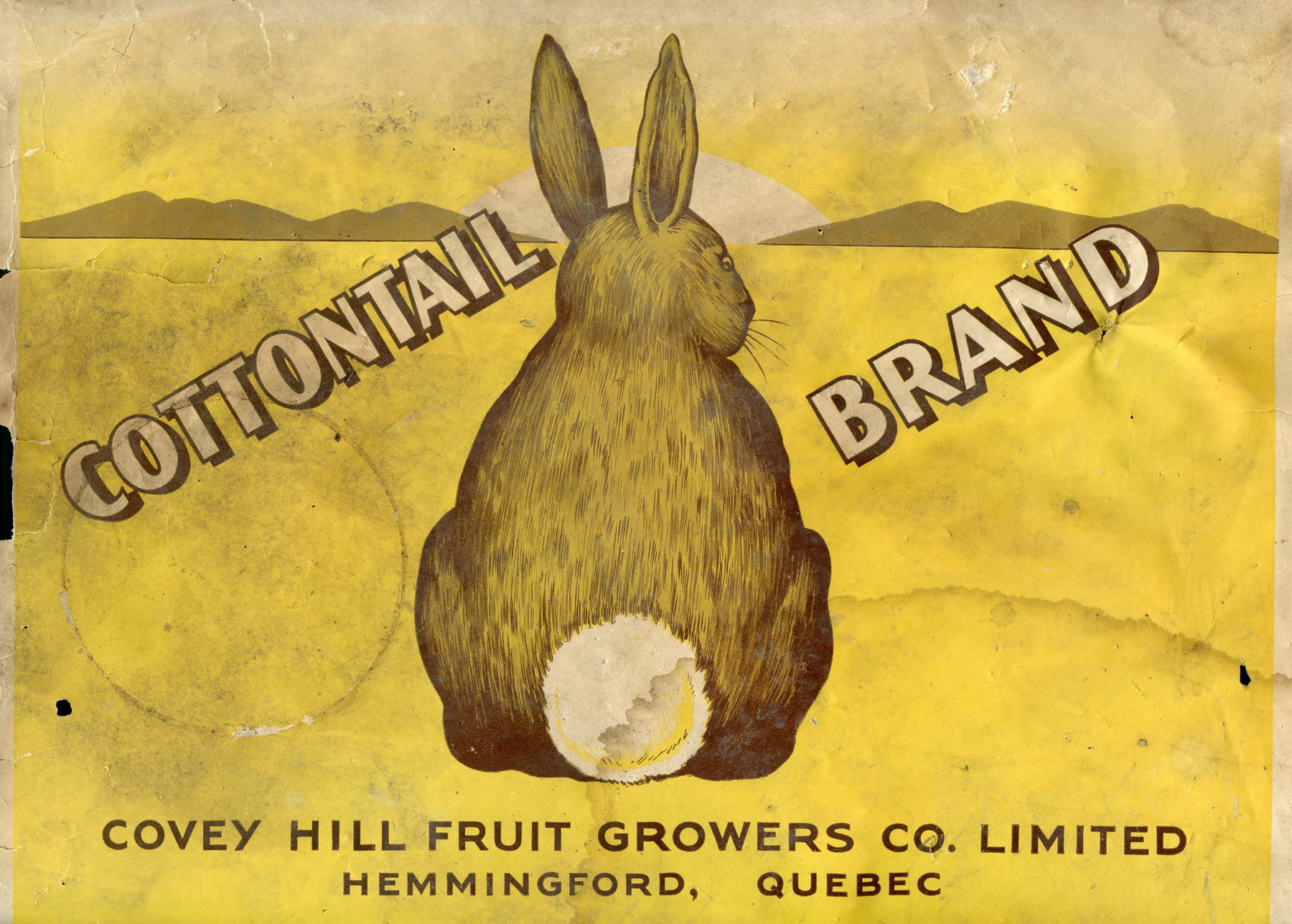

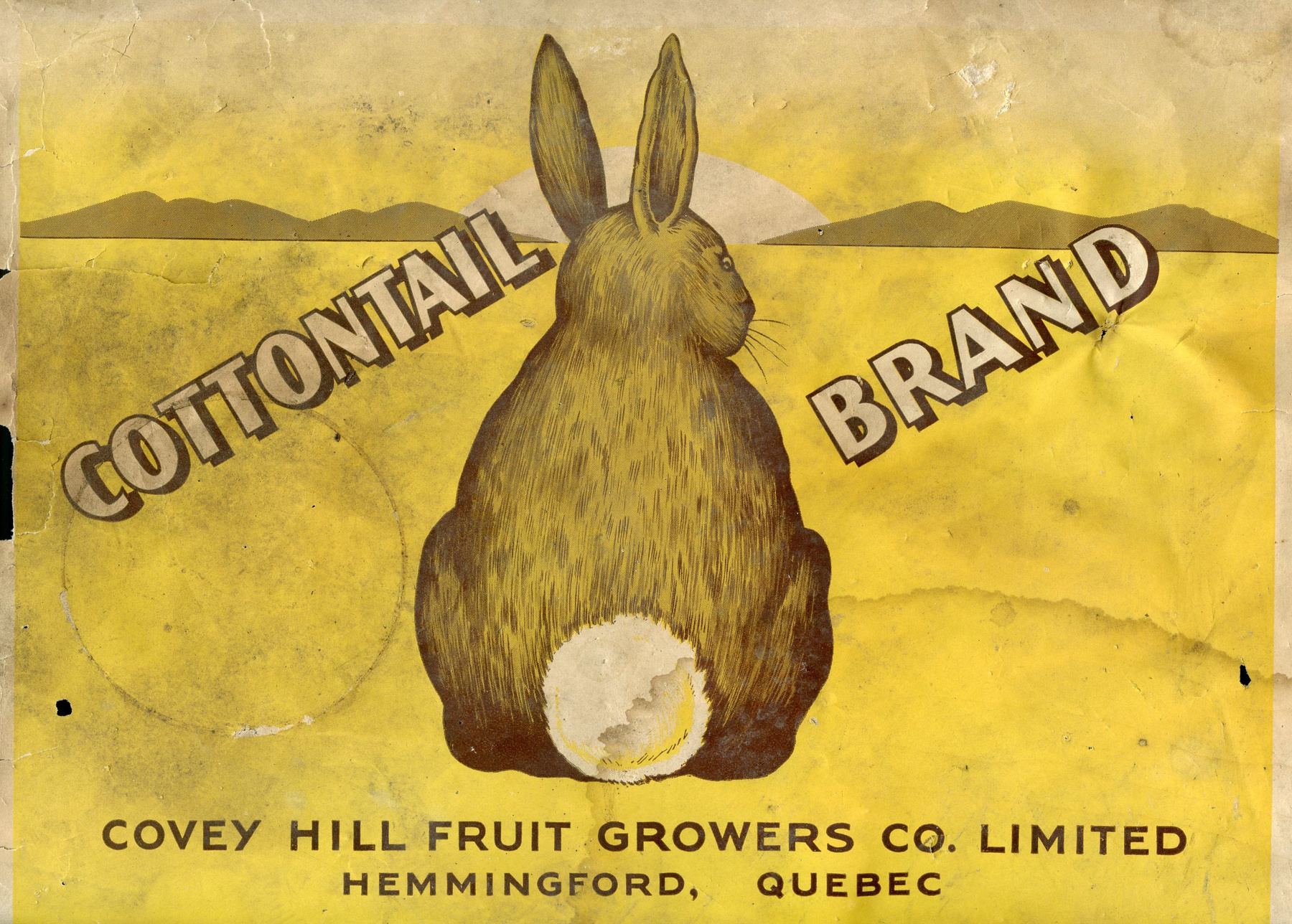

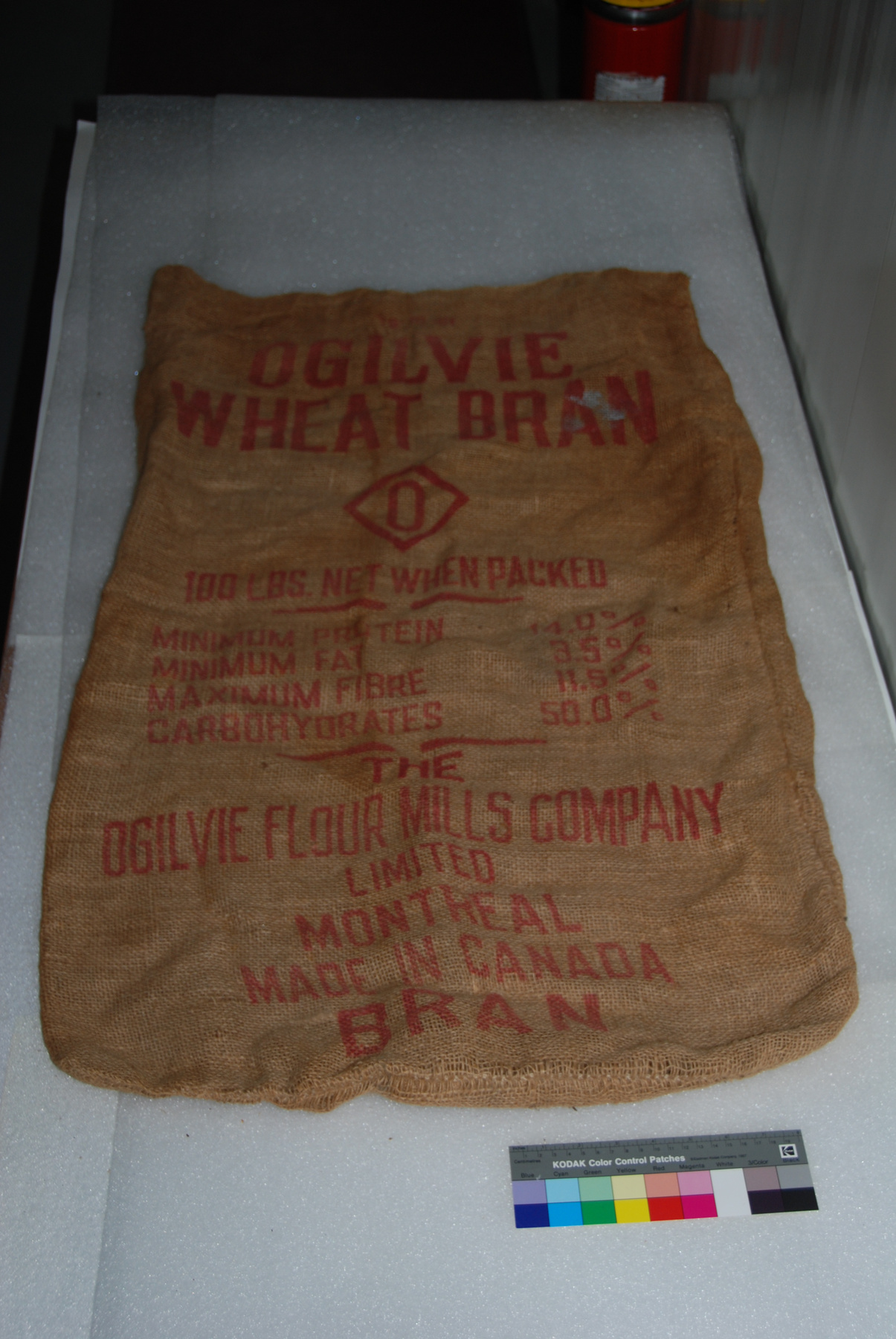

Used at a Canadian orchard co-op packing-house on Covey Hill in Quebec's Eastern townships. - Fonction

-

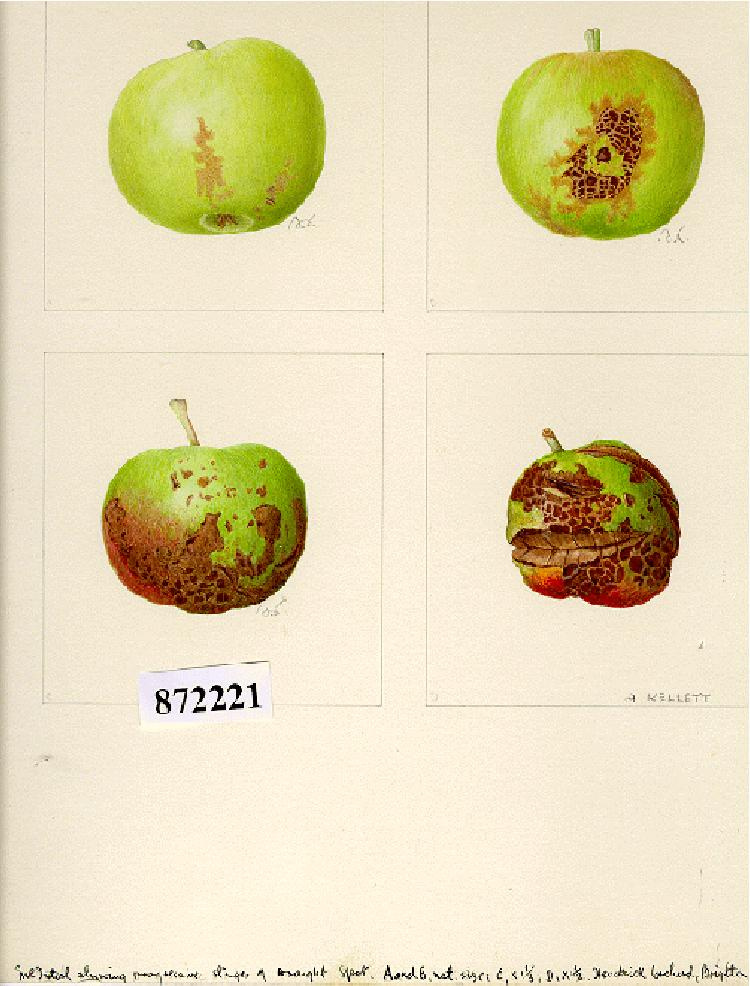

Small-scale packing line composed of multiple manual and mechanized components aiding in the sorting, sizing, and packing of produce. Specifically used to sort orchard fruits – apples mostly. - Technique

-

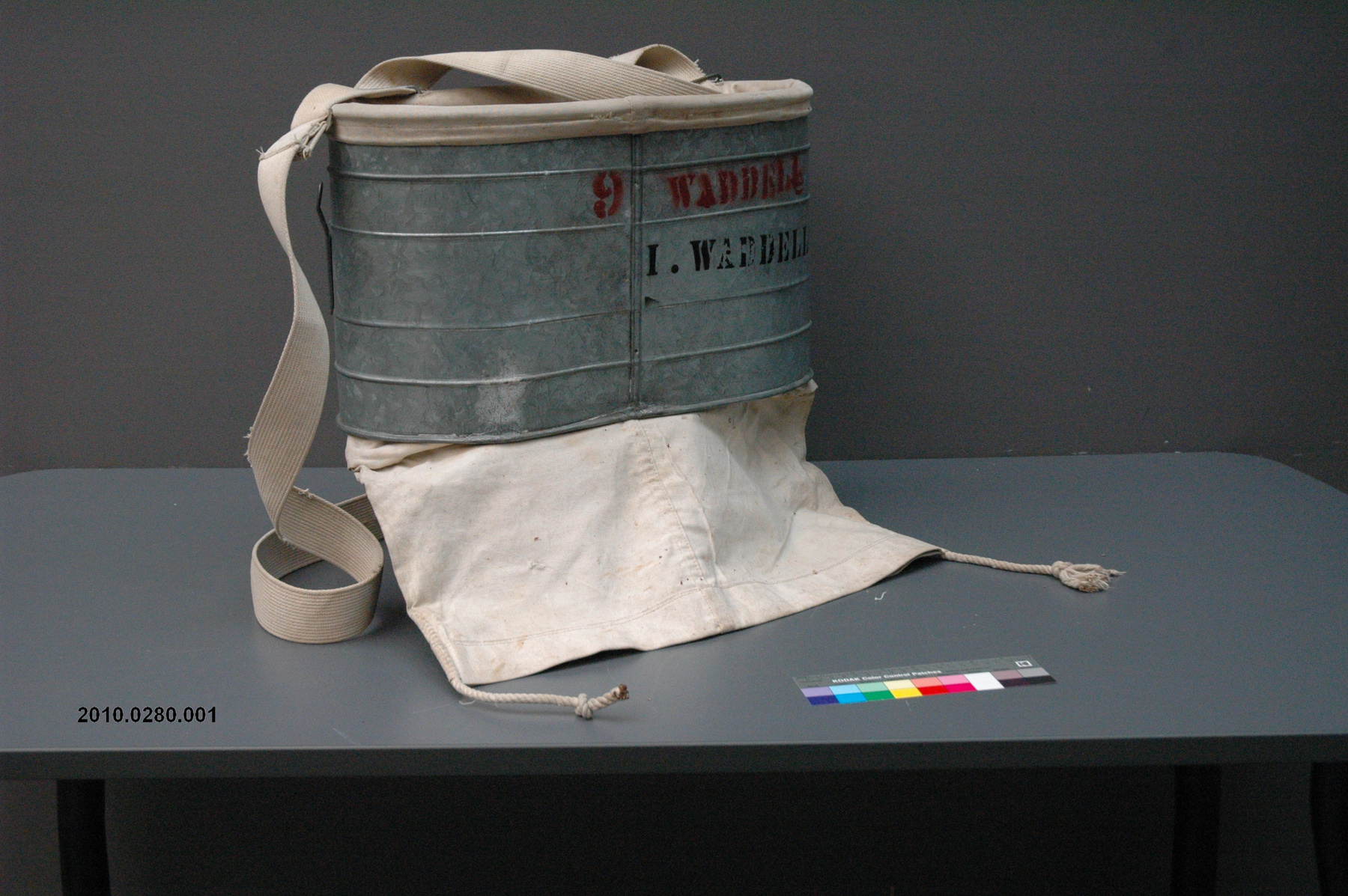

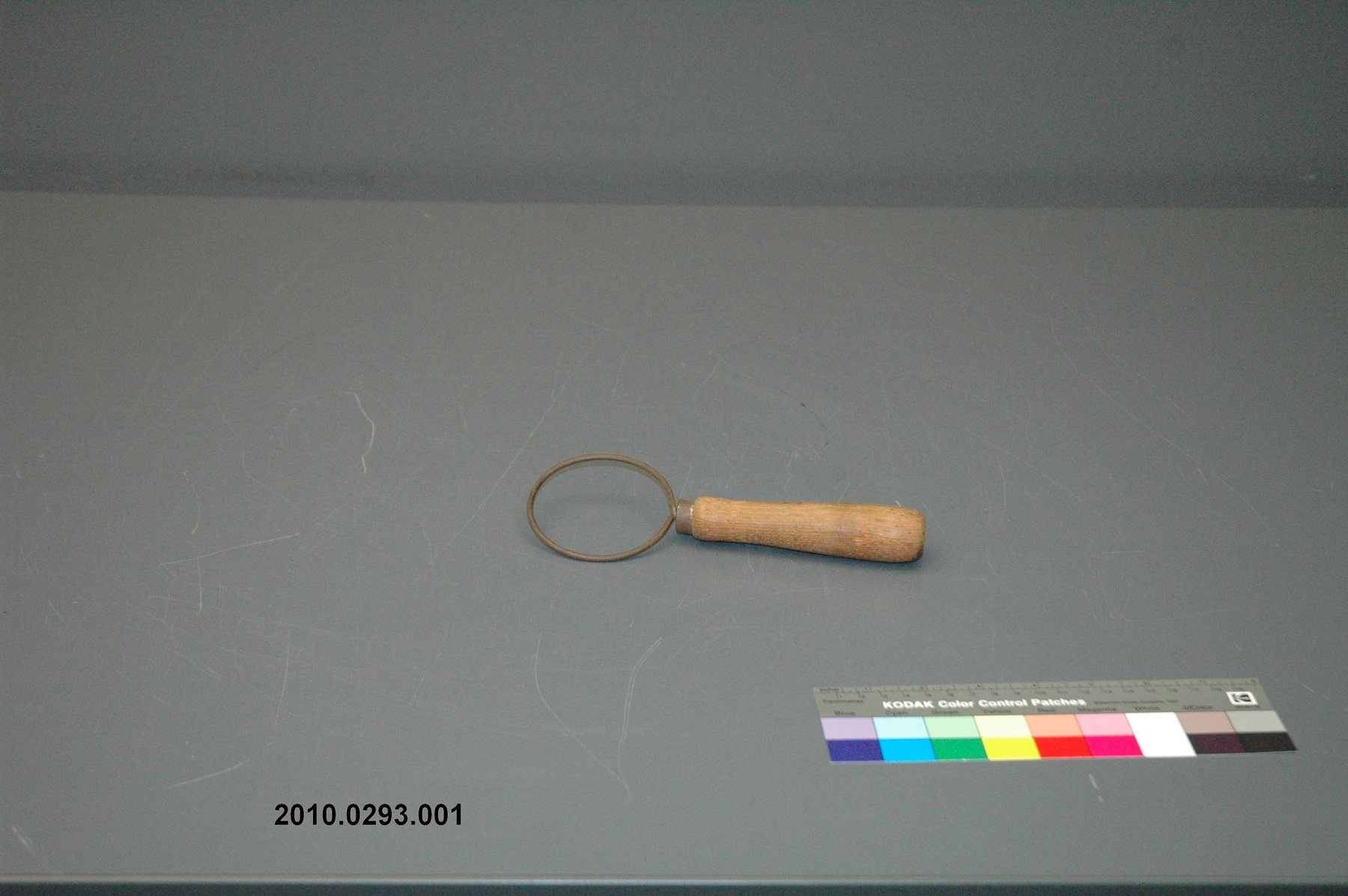

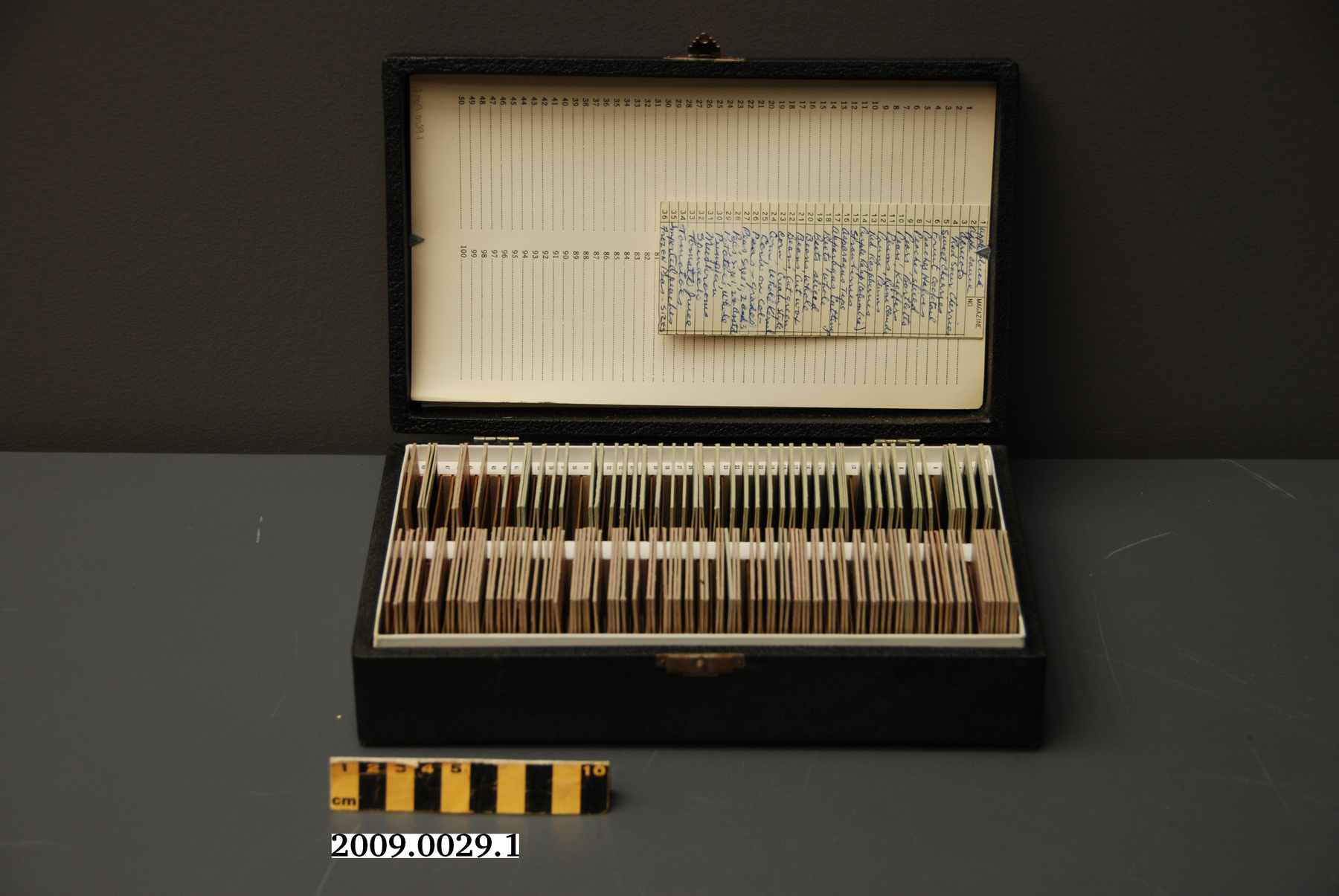

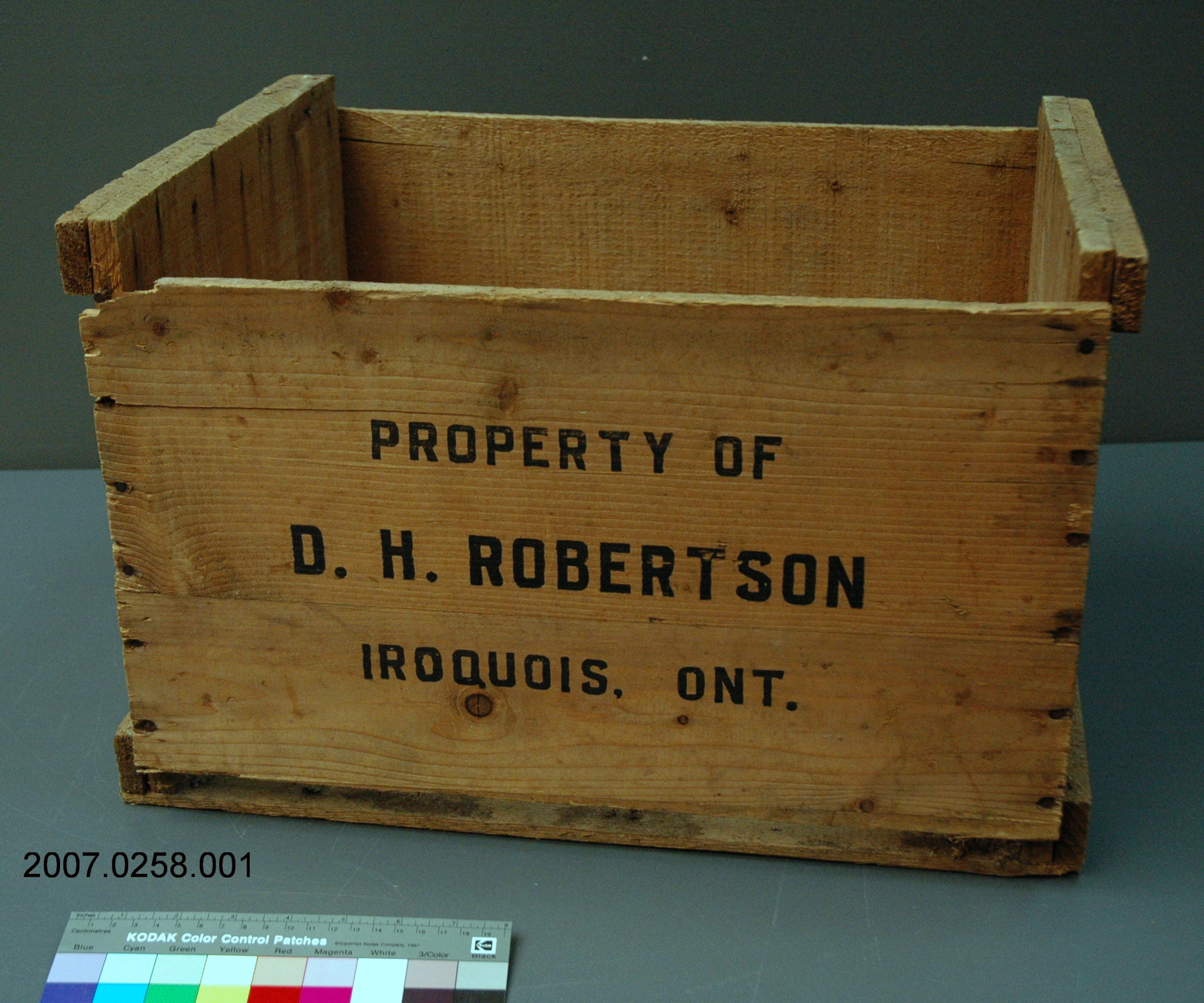

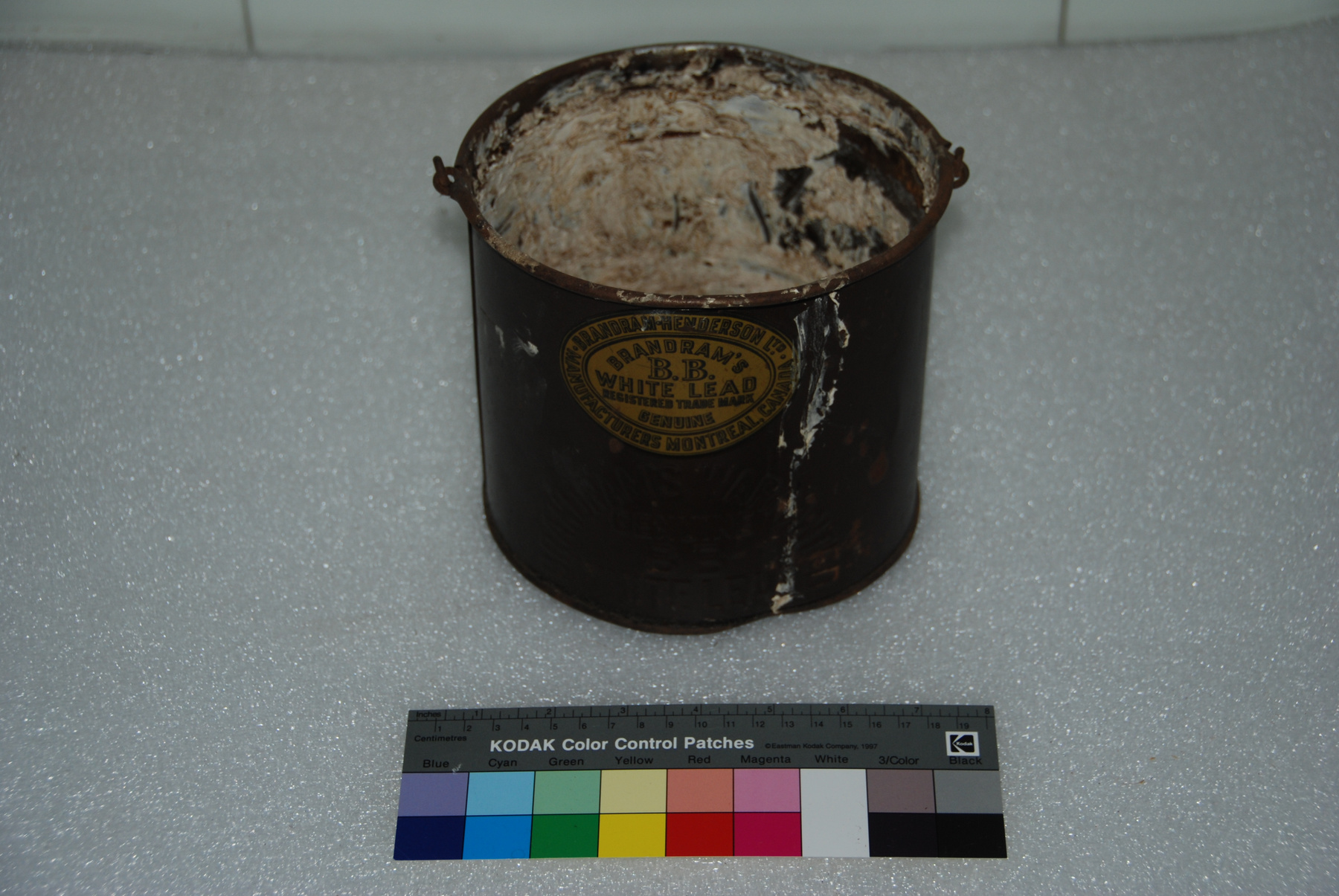

Before the advent of high-tech mechanisation, packing fruit was a labourious multi-step process. The grading, sorting and packing of fruit usually took place under one roof – more specifically, a packing house. Several pieces of equipment were used in conjunction to complete each step. Here is the process, broken down for this specific combination of equipment; using apples as an example of fruit being processed. Commonly referred to as ‘dumping’, a labourer grabbed a box of apples and emptied its contents onto a hopper (.002) – the entry point of the packing line. From there, the apples were fed onto a chain-driven roller conveyor (.003) where two labourers were tasked with sorting the culls from the grade apples. This step involved thorough visual inspections and manipulations so that the apples could be properly sorted and sent down the right conveyors. The conveying system was powered by a single motor (.024) and was made-up of a multitude of components: troughs (.010 & .011) set on a large frame (.009), conveyor belts (.020-.021) and drive shafts – like .018 and .019. When arriving on the sizing belt, the apples moved passed a series of ‘kicker’ wheels that were designed to expel apples, according to their sizes, into distinct packing bins (.013). As they went down the line, the apples were expelled systematically from largest to smallest. Sometimes, oversized fruit would get stuck or pinched underneath the kicker wheels; this was problematic as it clogged-up and slowed down the entire system. To prevent such a problem from occurring, the conveyor was equipped with an anti-jamming mechanism consisting of a series of brushes placed after each kicker the wheel. Set at specific heights, the brushes simply knocked oversized fruit off the belt before they could reach the next sizing wheel. When expelled from the sizing belt, the apples accumulated in bins or ‘packing stations’ (.013-.017). A labourer manned each station. Equipped with a packing table, packing tissues, liners, and multiple storage containers, a ‘packer’ would wrap each individual apple in a piece of tissue paper and place it in a box or basket. Apples had to be packed firmly so as to reduce the likelihood of having loose apples bouncing around and damaging the surrounding fruit. Once packed, the containers were sent to a lid-press to be sealed before being stamped and shipped to market. - Notes sur la région

-

Inconnu

Détails

- Marques

- S/O

- Manque

- Multiple components missing. Fruit & vegetable grader & sizer was not acquired in its entirety. See multimedia tab for pictures of fully assembled system.

- Fini

- Inconnu

- Décoration

- S/O

FAIRE RÉFÉRENCE À CET OBJET

Si vous souhaitez publier de l’information sur cet objet de collection, veuillez indiquer ce qui suit :

Wayland Machinery Co. Inc., Grader & sizer, fruit & vegetable, vers 1930, Numéro de l'artefact 2010.0294, Ingenium - Musées des sciences et de l'innovation du Canada, http://collection.ingeniumcanada.org/fr/item/2010.0294.001/

RÉTROACTION

Envoyer une question ou un commentaire sur cet artefact.

Plus comme ceci